Posts: 250

Threads: 12

Joined: Dec 2008

Charlie, is this a standalone shelf or is it going to be integrated into your layout?

300ft of track!!!! and for a display yard that is for rolling stock currently in boxes....... you must have a gazillion units in your RR company. ;-)

It will be great to see them all.

Jack

LIFE....

..... Abandon the search for truth

Look for a good fantasy

Posts: 604

Threads: 12

Joined: Jun 2022

That's gonna be awesome! My own storage yard is hidden under my viewing level. Makes things very compact, but there are countless times when I wish it was all right in front of me.

Posts: 5,160

Threads: 100

Joined: Dec 2008

Hi Charlie---during your last visit you suggested the idea of a second level for the Leetown Division---thanks for your inspiration and these recent pictures from the Wilderson Division.Like yourself I have the need for additional trackage to show all those locomotives and rolling stock that are hidden away in their boxes---a good time to get motivated and start a similiar project on the Leetown Division.

Posts: 2,090

Threads: 40

Joined: Dec 2008

This should prove to be interesting since eventually I would like to add something similar. I am very curious to see how it works out and how it is put together.

Posts: 9,732

Threads: 233

Joined: Dec 2008

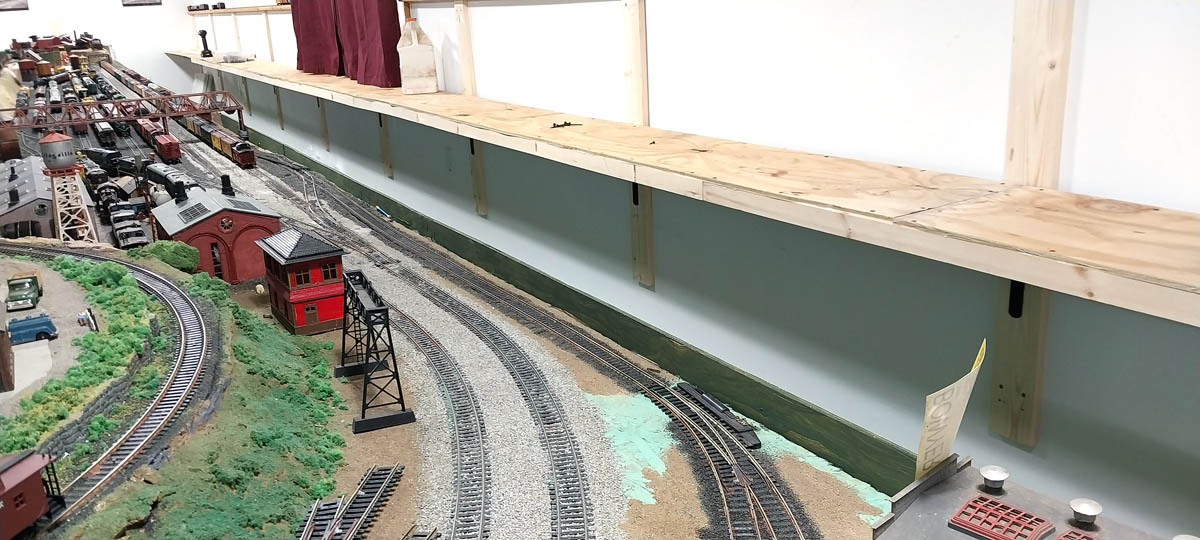

This morning I waited for a little heat from the sun so I could cut the plywood outside. I cut it 12 inches wide. Usually I would rip 1x2s from 2x4s but my table saw had quit and I did' ent to take time to check it out so I ordered some 1x2s and 1x4s from Home Depot for curbside pick up (the closest store is 10 miles but the other direction the store is 15 miles but the price was all most 40 percent cheaper). These were some beautiful strips though the wood came from Sweden.

I glued a 1x2 with the 2 inch side flat against the length of the plywood in the rear and screwed it every 12 inches. I staggered them so the joints were in the center of the 8 foot plywood run. (I used plywood because I had some left from a project) I cut 1x4 blocks and placed them on the braces to keep the shelf flat and glued them to the plywood and screwed the shelf to the braces. Next I glued and screwed the 1x2s to the front edge with the 1 inch side to the plywood.

At that point my back and legs had had it so tomorrow will continue with the other wall which is only 16 feet. I will take some photos of that construction that will show the screwing and glueing in more detail.

Charlie

Posts: 604

Threads: 12

Joined: Jun 2022

You made quick work of that! What's the plan for the curtains?

Posts: 9,732

Threads: 233

Joined: Dec 2008

Hello Blue.

Todd, the curtains will be shortened 5 inches. (My wife made them, she can shorten them). I keep them closed so I don't have sun fading everything. Had I been thinking in the beginning I would not have had windows. They are triple pane made from freezer doors I was given. They are heavy, and will open but it seldom gets that warm in the train building. I insulated it very heavy and caulked every seam that could leak air or allow bugs and mice.

Today I put the shelf on the north side and tied it in I am attaching pictures of the construction described above. I used lots of glue and screws to keep it together and that also adds some strength to the light weight construction. I am short about 12 feet of 1x2 for the front edge but I have 3 extra 1x4's so I will cut one to get those pieces. Early quit because I need to let the advil kick in. Maybe so more this evening.

Charlie

Posts: 9,732

Threads: 233

Joined: Dec 2008

I didn't get much visible work done today but I got the remainder of the support screws in and did a little filing of some rough edges,

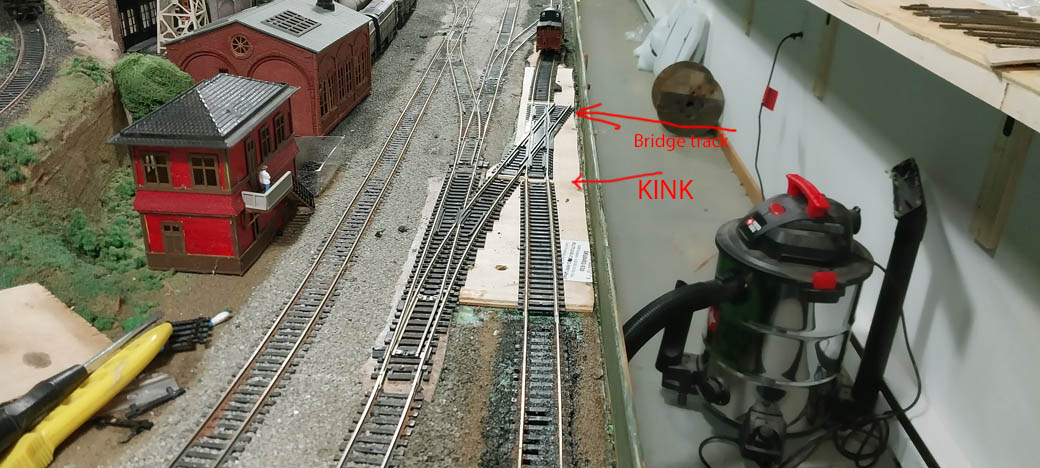

I figured it was time to start building track from the main line. I had room for one #6 switch from the outer main but had to cross a siding. I have a 12.5 degree crossing that will work with only minor adaption. Here are some pictures with the section of track cut out

The beauty of using white glue and water to hold the ballast and track down is a little bit of water and a couple minutes soak time and the track can be removed. I made the cut for the switch before I softened the glue, then removed that section and cleaned the base with a scraper and tidied up with my shop vac. It looks like a short 3 inch piece of flex track between the switch (turnout) and the crossing will allow the slight 1 or 2 degree curve to keep the industrial siding straight.

I will let the site dry overnight and tomorrow finish that up. The removable bridge will head out the other side of the crossing.

Charlie

Posts: 2,090

Threads: 40

Joined: Dec 2008

Posts: 604

Threads: 12

Joined: Jun 2022

Looking forward to seeing how you approach the removable sections, Charlie.

Posts: 9,732

Threads: 233

Joined: Dec 2008

I installed the switch from the main and the crossing on the siding and connected them I noticed in the photo a small kink I can easily remove before I put down ballast. It is on an industrial siding so a kink isn't a problem but it is a very easy fix. I will lay ties under the joints before ballast. The tracl level is the same on both sides although it looks like the shelf is higher. I have put my level on it at least 5 times because it looks higher to the eye too but it isn't It went well and I did not work long today.

Charlie

Posts: 9,732

Threads: 233

Joined: Dec 2008

I did begin to make the tie in bridge for the one end. I am not an engineer by any means so I have to work things out It is really only going to be a board with track to run a train from one section to another so it must support a good section of track and be sturdy when in place and easy to install and remove. I can all ready see I can spend a lot of time with the shelf making and sorting trains to run on the main. Here is what I have so far.

Charlie

Posts: 2,090

Threads: 40

Joined: Dec 2008

Good job so far.

The shelf yard should make for some interesting times.

Posts: 9,732

Threads: 233

Joined: Dec 2008

I ballasted the new switch and the new track yesterday and it is glued in place. It should be dry enough to work on the lift out today.

I am thinking of using a section of flex track 4 foot long that is easily removed from the lift out which will make it easier than a permanent mounted track with small sections on either end (like the modular groups use) I have some ideas that should work.

to be continued

Charlie

Posts: 9,732

Threads: 233

Joined: Dec 2008

I managed to get some track down and i was hoping to get it glued and ballasted but that is not in the cards today. I want to get it a little straighter. I really am not that fussy. I haven't decided whether to use the old black cinder ballast or Limestone. I will decide in the morning

. There is about 75 feet of storage track here, and there will be about 150 feet in the center yard with another 75 feet in the west yard which will probably be for coaches. Subject to change according to how i feel

Charlie