Posts: 1,817

Threads: 27

Joined: Dec 2009

It's coming along ... and looking good!

biL

Lehigh Susquehanna & Western

"America will never be destroyed from the outside. If we falter and lose our freedoms, it will be because we destroyed ourselves." ~~Abraham Lincoln

Posts: 88

Threads: 1

Joined: Oct 2010

Seeking ideas for an index system for the center track.

![[Image: plate1.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/plate1.jpg)

Posts: 1,817

Threads: 27

Joined: Dec 2009

What is the material under the pivoting track? :?:

What is the material under that track the the pivoting track sits on? :?:

I have a couple of potential ideas, but they all sort of have a dependence on materials.

That said, I had been wondering about that rear track. :?

I had assumed it was there for appearance sake, but I never noticed the pivoting track.

Great idea for getting the most out of a very small area.

biL

Lehigh Susquehanna & Western

"America will never be destroyed from the outside. If we falter and lose our freedoms, it will be because we destroyed ourselves." ~~Abraham Lincoln

Posts: 88

Threads: 1

Joined: Oct 2010

Hey Bil. The pivoting track is mounted on thin plywood (4mm+/-) with matboard roadbed, as is the rest of the track. The cut out indexing area is inset with smooth masonite so that all the rail is flush. A little tricky to get it all level, but it's simple, and works great. The "sector plate" as I've come to know it, is a common micro layout device popularized on this site:

<!-- m --><a class="postlink" href="http://www.carendt.com/scrapbook/page91a/index.html">http://www.carendt.com/scrapbook/page91a/index.html</a><!-- m -->

I've come across pages on the indexing subject before, just need to work out the details. Leaning towards a horizontally sprung ball-in-tube type arrangement. Want to be able to hear and feel a gently aligned "click" since the plate area will be mostly hidden by a bridge and building flat. until I get to rooting through my misc. harware bins, eyeballing will have to do.

Found the page I was thinking of: <!-- m --><a class="postlink" href="http://www.carendt.us/scrapbook/page45a/index.html">http://www.carendt.us/scrapbook/page45a/index.html</a><!-- m -->

I think the vertical bolt mount might push my plate up too much and out of flush. Fun challenge, this mini engineering!

Posts: 1,229

Threads: 23

Joined: Dec 2008

Why not just make a little mark on the throw rod itself? Align the track then nick the rod with a sharp knife or file or paint at the point where it exits the tube. Sure, it's not locking, but it'll get you there until you develop another method.

Another mechanical idea would be a stop block you can raise or lower.

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 88

Threads: 1

Joined: Oct 2010

Well I spent a couple of hours trying to build a surface mounted wire spring type indexer to no avail. Would prefer not to have to reach into the plate area, but that can wait. sticking with simple for now, thanks Galen.

Switching gears, I decided to get into the structures. Something I know I can do and show some real progress. Started with the ubiquitous "bridge" scene divider. A first for me. I see why it's used so often on micros. Big difference! Really helped bring back some motivation. Roughed in the factory flat behind the kick back too. Backdrop and fascia next.

![[Image: Bridge1.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/Bridge1.jpg)

Posts: 88

Threads: 1

Joined: Oct 2010

Slow but steady progress. I just reserved a table for the April 3rd RCT&HS Leesport Pa. meet at the Leesport Farmers market. You can see Carbon Corner here live and in person. Now that there's a deadline, I'll be getting this thing tuned up quick!

![[Image: CC1aa.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/CC1aa.jpg)

Posts: 612

Threads: 10

Joined: Feb 2011

Mr Bill

It might interest you to know that Effingham RailRoad EFRR 2716 was a former Reading switcher 2716.

It now wears EFRR Phase 2 paintwork inspired I believe by the Chicago and Great Western paint scheme.

Mark

Fake It till you Make It, then Fake It some More

Posts: 88

Threads: 1

Joined: Oct 2010

Took the layout to the show april 3rd. Got the fascia on and a pedestal built to provide a nice viewing height, and to be able to put sale items and stuff beneath it. I use project liguid nails (slow setting) for the major foam contact areas, and then gusset the connections with mat board and hot glue once it's square. Works great for being able to keep construction and operations moving along.

![[Image: Leesport4-3-11.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/Leesport4-3-11.jpg)

![[Image: Base1.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/Base1.jpg)

Posts: 88

Threads: 1

Joined: Oct 2010

Posts: 931

Threads: 68

Joined: Dec 2008

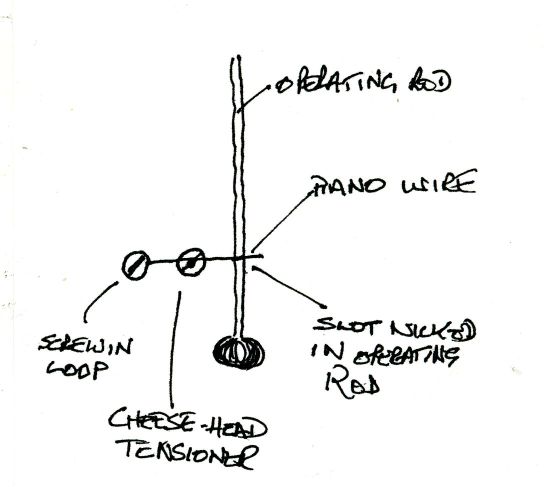

Sorry to pick up on this rather late on, however - re indexing - easiest would be to take a fine sharpie align the centre track and make a mark on the rod. Take a small triangular file, and make a nick in the top surface of the rod at that point - visit a music shop and get either a guitar string or some piano wire, bend a loop in the end to takes a screw, and screw it down so the wire clicks into the nick - take a cheesehead screw and screw it down on top of the wire so that it gives some tension, and it should click into the nick and lock it - hope it helps

Posts: 1,229

Threads: 23

Joined: Dec 2008

Ummm...cheese head? Is that the technical name? Sounds like a screw from Wisconsin.

Interesting concept.

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 931

Threads: 68

Joined: Dec 2008

A cheese-head screw is one where the underside of the head is flat, rather than countersunk - in this case it will bear down on the wire to provide tension

Posts: 1,229

Threads: 23

Joined: Dec 2008

Well, there you go! Nice to learn something everyday.

Your description was more than enough to figure out how a 'cheesehead' screw functioned so I got the concept right away...I had just never heard that name before. Maintaining the tension on the wire would be critical to the success of this mechanism, to ensure a constant alignment while moving over the gap.

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 229

Threads: 22

Joined: Dec 2008

shortliner Wrote:A cheese-head screw is one where the underside of the head is flat, rather than countersunk - in this case it will bear down on the wire to provide tension Oh, a Pan-Head Screw...

|

![[Image: plate1.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/plate1.jpg)

![[Image: Bridge1.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/Bridge1.jpg)

![[Image: CC1aa.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/CC1aa.jpg)

![[Image: Leesport4-3-11.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/Leesport4-3-11.jpg)

![[Image: Base1.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/Base1.jpg)

![[Image: ops7-24-11.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/ops7-24-11.jpg)

![[Image: flat1.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/flat1.jpg)

![[Image: flat2.jpg]](http://i454.photobucket.com/albums/qq261/MrBill/flat2.jpg)