08-09-2011, 02:18 PM

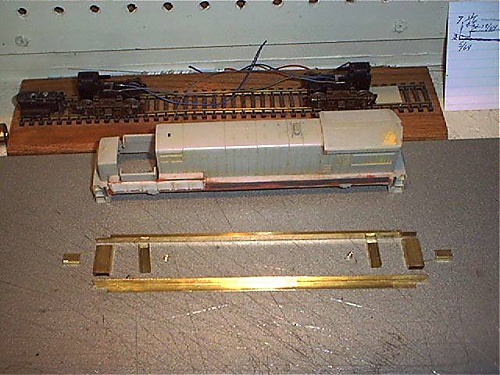

This is the start of the brass frame.

The frame rails are 7/32" x 7/32" angles cut to 7 11/16" and notched to clear the steps.

The end cross members are 3/16" x 3/8" rectangular tubing cut to 3/4".

The bolsters and coupler mounting pads are 1/4" x 1/8" channel.

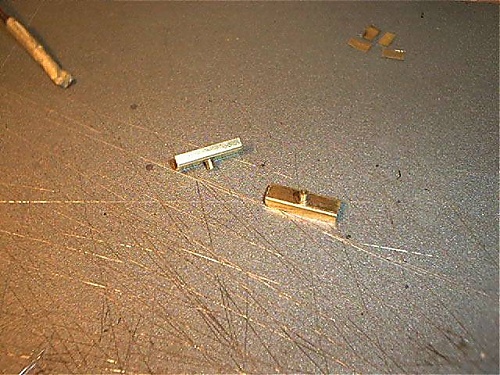

The king pins were turned on the lathe. They are 3/32" dia. and 1/8" long with a .050" high and 1/8" dia. head.

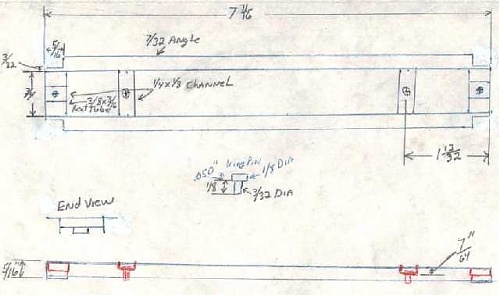

This is a crude drawing showing dimensions.

3/32" holes were drilled in the bolsters and the king pins were inserted and soldered in place.

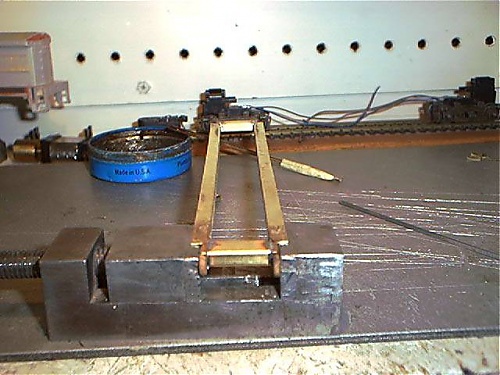

The frame rails and end cross members were clamped to a piece of wood and soldered.

To solder the tops of the cross member, the frame was clamped in a vise with Popsicle sticks as insulators.

The frame rails are 7/32" x 7/32" angles cut to 7 11/16" and notched to clear the steps.

The end cross members are 3/16" x 3/8" rectangular tubing cut to 3/4".

The bolsters and coupler mounting pads are 1/4" x 1/8" channel.

The king pins were turned on the lathe. They are 3/32" dia. and 1/8" long with a .050" high and 1/8" dia. head.

This is a crude drawing showing dimensions.

3/32" holes were drilled in the bolsters and the king pins were inserted and soldered in place.

The frame rails and end cross members were clamped to a piece of wood and soldered.

To solder the tops of the cross member, the frame was clamped in a vise with Popsicle sticks as insulators.

Ray Marinaccio