Posts: 1,263

Threads: 45

Joined: Feb 2010

alcanman Wrote:Going back to the pic of the Transload shed at DeLand, I'm now thinking that such a structure would perfectly fit on the team track at Palmetto. However, I am wondering how the structure would look from the trackside? Presumably, it would be open with piping/apparatus to discharge the plastic pellets from a hopper car into a truck. Also, it difficult to see on Google but it looks the roof of the structure provides cover for a truck whilst loading is proceeding.

Can anyone help, or provide pics of similar structures?

Thanks again,

Mal Mal;

The photos of this very simple trans-load shed have really peaked my interest and I've been looking at this quite a bit using Google/Bing and studying the photos you found. From what I can make out, I'd say that the track side of this structure is completely (or perhaps partially) open, with only small pipe like supports and bracing for the roof. You can tell what I mean by looking at the right side of the structure:

The really odd thing about this facility is that there appears to be only the single unloading pipe that runs over the top of the shed as you can see here - an interesting modeling detail in itself:

I can't see any evidence of there being an unloading pipe running parallel to the track, which would allow the consignee to connect and unload more than one car at a time. That's the usual procedure at most all of the plastics facilities that I've seen.

They no doubt have a connecting hose that is long enough to allow connecting to all the hoppers on the car, but that begs the question, how are they moving the cars if they need to unload more than one car between the times that the CSX local works the facility? With as many cars as you see waiting to be unloaded, it really bothers me that they seem to be able to only unload a single car per day. I suppose they could let gravity move a car or two down toward the switch to access additional cars, but still looks like they would be very limited as to the number of cars they could unload in a days time.

Still, it would make for a very interesting small footprint structure on a team/trans-load track on a switching layout, not to mention an unusual looking structure. It could certainly represent the trans-load facility for a small off-line plastics plant that only receives a car now and then. I know of one small plastics plant in Madison, IN, on the CMPA (Meese Orbitron Dunne Co http://www.meeseinc.com/), that receives only one or two cars of plastics pellets per week. So no reason that you couldn't have a similar off-line facility.

Ed

"Friends don't let friends build Timesavers"

Posts: 258

Threads: 8

Joined: May 2011

Thanks Ed,

Your comments are really helpful.

Like you, I've become increasingly fascinated by this little structure and have been looking more closely on Google Earth.

I hadn't realised that the structure could also be seen in the first pic

It does looks like the structure is open at each end and front (trackside)

Also, I'm a bit troubled about how they could unload so many cars without a switcher.

This has really focused my attention back to Palmetto and with the help of the 2 pics, I'm hoping to build a similar

transload facility which will fit on the team track. It will be nice to have a small structure and a specific commodity (plastics pellets) being delivered

to the team track, although I can still spot the occasional gon or bulkhead flatcar further along the track.

I've already picked up an Atlas 5701 pellet car quite cheaply here in the UK. At the weekend I'm off to the Newcastle -upon-Tyne show

(see Shortliners earlier thread) to see Jon Grant's superb ' Sweethome Alabama' which is making it's first appearance at a train show.

Thanks again,

Mal

Layout videos - <!-- m --><a class="postlink" href="http://www.youtube.com/user/Alcanman1">http://www.youtube.com/user/Alcanman1</a><!-- m -->

New Westbrook <!-- l --><a class="postlink-local" href="http://bigbluetrains.com/forum/viewtopic.php?f=46&t=8888">viewtopic.php?f=46&t=8888</a><!-- l -->

Posts: 1,263

Threads: 45

Joined: Feb 2010

Happy that my examination of this facility helps. Currently, I have a similar arrangement on my current ISL plan, although I'll be trans-loading feed and/or fertilizer from covered hoppers to trucks using a simple auger type conveyor. I do have the appropriate type of truck for an operation like that - so that gives me a destination for all my gravity discharge covered hoppers and what I hope will make for a nice small scene on the trans-load track. The cars wouldn't have to be moved while being unloaded, as the conveyor would be moved if more than one car is on spot at a time.

Ed

"Friends don't let friends build Timesavers"

Posts: 3,730

Threads: 44

Joined: Dec 2008

Good to see a Florida based layout!

Mike

Sent from my pocket calculator using two tin cans and a string

Posts: 100

Threads: 8

Joined: Sep 2010

Southern Tuxedo Wrote:Paulman,

Do you have any additional pictures of the White Road Boss truck? I'm always interested in how industries move railcars when a locomotive isn't present.

Mark Mark, afraid not. I didn't get that close to it...

Posts: 258

Threads: 8

Joined: May 2011

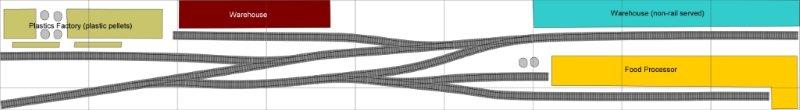

alcanman Wrote:Hi,

I would like a different track arrangement from Palmetto, so I've included a run-around with a trailing spur

leading to a Food Processor or Warehouse.

Mal

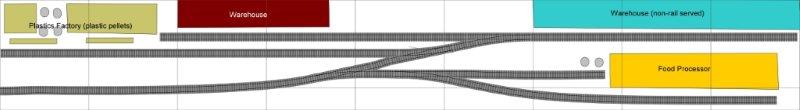

Hi, I recently bought a copy of Lance Mindheim's latest book, 'How to operate a Modern Era switching layout'. Once again, he advocates dispensing with

a run-around, particularly when planning a small switching layout. I decided to re-visit my plan and came up with a new one, which assumes that the run-around

is further along the line, offstage. A small spur has been added at the Food Processor for tank cars.

Trains are staged on the track in front of the non-rail served warehouse from where the loco pulls cars to switch the Food Processor and return to the staging

track. Cars are removed and replaced with new ones, with the loco shoving cars into the Plastic facility for switching.

Here's the old plan, for comparison

Which plan do you prefer, and why?

regards,

Mal

Layout videos - <!-- m --><a class="postlink" href="http://www.youtube.com/user/Alcanman1">http://www.youtube.com/user/Alcanman1</a><!-- m -->

New Westbrook <!-- l --><a class="postlink-local" href="http://bigbluetrains.com/forum/viewtopic.php?f=46&t=8888">viewtopic.php?f=46&t=8888</a><!-- l -->

Posts: 3,730

Threads: 44

Joined: Dec 2008

Mal I like the second one better. To me it's more visually interesting and has more operating possiblities.

Mike

Sent from my pocket calculator using two tin cans and a string

Posts: 1,263

Threads: 45

Joined: Feb 2010

Although you can find plenty of industrial spurs where the tracks run in both directions without a runaround track on the spur; in this case, I'd be inclined to go with plan variation #2 or something similar with the runaround track.

Not only could this plan represent an industrial spur off the main track, it could also be a separately operated short line or switching company. In that scenario, 2 or 3 interchange cars could be staged by the non-rail served warehouse and then switched accordingly, with your operating session ending by placing your outbound cars back on the interchange. That would also eliminate the need to re-stage your train in the middle of the operating session.

Not sure if it would work well or not, but you could also possibly operate either plan with two locomotives as Progressive Rail used to do at their Lakeville, MN operation. Just a thought.

Plan #2 actually resembles the Effingham Railroad in many ways and that might give you some ideas too.

Ed

"Friends don't let friends build Timesavers"

Posts: 931

Threads: 68

Joined: Dec 2008

Mal, #2 but remove the turnout at the RH end eiden the space behind the food processor and add a single reack sector plate behind it, feedin both the loop tracks

Posts: 258

Threads: 8

Joined: May 2011

Thanks to all for the replies.

Interesting that you all preferred plan #2 with the run-around, my original plan. My main concern with plan #1 was having to remove cars from the layout half-way thru a switching session.

I actually built a layout similar to plan #2 a few years ago, I think it was based on a plan called 'two nooks or double inglenook' and was attributed to a certain 'Shortliner'

The layout worked really well and was my last DC layout, then a I caught the DCC bug!

After reading your comments, I'm steering back to plan #2.

Thanks,

Mal

Layout videos - <!-- m --><a class="postlink" href="http://www.youtube.com/user/Alcanman1">http://www.youtube.com/user/Alcanman1</a><!-- m -->

New Westbrook <!-- l --><a class="postlink-local" href="http://bigbluetrains.com/forum/viewtopic.php?f=46&t=8888">viewtopic.php?f=46&t=8888</a><!-- l -->

Posts: 234

Threads: 4

Joined: Oct 2010

shortliner Wrote:Mal, #2 but remove the turnout at the RH end eiden the space behind the food processor and add a single reack sector plate behind it, feedin both the loop tracks

Jack,

Why do you recommend the use of a sector plate? Would it be to give the run around tracks more length and thereby make it look better and more prototypical? How long would you make the sector plate?

I understand why you would use one to save space when you have multiple tracks to switch to, but in this case I am a little confused as I don't see it saving too much space. I wondering if I am missing something here.

Mark

Posts: 931

Threads: 68

Joined: Dec 2008

It will give you a longer run-round in the loop as the whole track becomes part of the runround - since it is hidden, it all becomes "off-layout " swtching track. If you make it a"plug in"board, with the pivot point a jackplug, you can add another foot to the end and extend your trackage - without affecting storage capability when not in use

Mal If you can add a couple of inches to the board width, with the food processor as a hollow shell, you might be able to make the sector plate "double -track" and have another train staged on the second track

Posts: 234

Threads: 4

Joined: Oct 2010

Ok thanks Jack.

It's starting to make a little more sense to me each time I read your reply and look at Mal's design. Thanks for taking the time to respond to my questions.

Mark

Posts: 931

Threads: 68

Joined: Dec 2008

Mark, those who don't ask stay puzzled forever - Thats what I'm here for!

Posts: 88

Threads: 1

Joined: Oct 2010

Another vote for #2 with a sector plate. Reduces the amount of turnouts, gets rid of the unrealistic timesaver motif, and opens up more spotting locations.

|