Posts: 931

Threads: 68

Joined: Dec 2008

This article refers to UK industries - but may be useful for ideas for industrial layouts <!-- m --><a class="postlink" href="http://www.igg.org.uk/gansg/12-linind/012-index.htm">http://www.igg.org.uk/gansg/12-linind/012-index.htm</a><!-- m -->

Posts: 180

Threads: 6

Joined: Feb 2013

Thanks all for the imput so far,here's a list of the c/hoppers i have.

PWRS ACF 4600 3-bay c/hopper,UP x3

Intermountian 4-bay cylindrical c/hopper,NHAX x2

Atlas ACF 3-bay cylindrical c/hopper, CSXT x2

Exactrail Evans 4780 c/hopper, FMC Chemicals x1

Athearn 54' 4700 c/hopper, FMC X1

Atlas ACF 4650 3-bay c/hopper, SSW x1

Walthers 50' airslide c/hopper, CSXT x2

Walthers Trinity 100t 2-bay c/hoppers, CSXT x2

would all of these still be in use in the period i plan to model 1990-2000??,if not could you give me some examples of c/hoppers that would be.

Ray

Posts: 1,263

Threads: 45

Joined: Feb 2010

long island jack Wrote:Thanks all for the imput so far,here's a list of the c/hoppers i have.

PWRS ACF 4600 3-bay c/hopper,UP x3

Intermountian 4-bay cylindrical c/hopper,NHAX x2

Atlas ACF 3-bay cylindrical c/hopper, CSXT x2

Exactrail Evans 4780 c/hopper, FMC Chemicals x1

Athearn 54' 4700 c/hopper, FMC X1

Atlas ACF 4650 3-bay c/hopper, SSW x1

Walthers 50' airslide c/hopper, CSXT x2

Walthers Trinity 100t 2-bay c/hoppers, CSXT x2

would all of these still be in use in the period i plan to model 1990-2000??,if not could you give me some examples of c/hoppers that would be.

Ray As for the reporting marks; CSXT, NAHX, SSW (UP), USLX (the FMC car), UP, those would all be valid for your era. I found examples of most of the cars you list and they all appear to be primarily used for grain/potash/fertilizer handling. The Trinity 100 ton 2 bay hoppers would be primarily used to transport cement.

There are plenty of the 50ft Airslide hoppers still in use transporting flour and sugar and I see them quite frequently around here, although as time goes on, they are rapidly being replaced with the newer pressure differential cars.

The Atlas cylindrical covered hopper is an early style ACF centerflow, first introduced around 1966. I haven't seen one one them in a long time, but no reason you couldn't use them on your layout. We had a fleet of them lettered for ACFX and SHPX assigned to National Distillers used for shipping distillers dried grain.

Looks like you've got plenty of covered hoppers for handling inbound grain, but only a couple that would handle sugar. I've looked at aerial views of several General Mills plants around the country and most of the cars visible in the views appear to be inbound grain. Most of the Kellog plants that I've been able to track down, don't appear to use rail service, even though they might be located close to a rail line! Go figure! Of course the final product would be shipped out via truck, although you could have inbound box car loads of packaging materials.

For what it's worth, I'd still try and have separate industries on your plan rather than try and make one large industry fit with your car fleet. Gives you a lot more flexibility.

Ed

"Friends don't let friends build Timesavers"

Posts: 255

Threads: 4

Joined: May 2010

FCIN Wrote:long island jack Wrote:Thanks all for the imput so far,here's a list of the c/hoppers i have.

PWRS ACF 4600 3-bay c/hopper,UP x3

Intermountian 4-bay cylindrical c/hopper,NHAX x2

Atlas ACF 3-bay cylindrical c/hopper, CSXT x2

Exactrail Evans 4780 c/hopper, FMC Chemicals x1

Athearn 54' 4700 c/hopper, FMC X1

Atlas ACF 4650 3-bay c/hopper, SSW x1

Walthers 50' airslide c/hopper, CSXT x2

Walthers Trinity 100t 2-bay c/hoppers, CSXT x2

would all of these still be in use in the period i plan to model 1990-2000??,if not could you give me some examples of c/hoppers that would be.

Ray As for the reporting marks; CSXT, NAHX, SSW (UP), USLX (the FMC car), UP, those would all be valid for your era. I found examples of most of the cars you list and they all appear to be primarily used for grain/potash/fertilizer handling. The Trinity 100 ton 2 bay hoppers would be primarily used to transport cement.

There are plenty of the 50ft Airslide hoppers still in use transporting flour and sugar and I see them quite frequently around here, although as time goes on, they are rapidly being replaced with the newer pressure differential cars.

The Atlas cylindrical covered hopper is an early style ACF centerflow, first introduced around 1966. I haven't seen one one them in a long time, but no reason you couldn't use them on your layout. We had a fleet of them lettered for ACFX and SHPX assigned to National Distillers used for shipping distillers dried grain.

Looks like you've got plenty of covered hoppers for handling inbound grain, but only a couple that would handle sugar. I've looked at aerial views of several General Mills plants around the country and most of the cars visible in the views appear to be inbound grain. Most of the Kellog plants that I've been able to track down, don't appear to use rail service, even though they might be located close to a rail line! Go figure! Of course the final product would be shipped out via truck, although you could have inbound box car loads of packaging materials.

For what it's worth, I'd still try and have separate industries on your plan rather than try and make one large industry fit with your car fleet. Gives you a lot more flexibility.

After retiring as a food microbiologist for a large Sara Lee Corporatiion bakery production facility, we also had a rail spur entering our plant, but was never used. All of our packaging as well as ingredients were trucked in. Packaging, both corrugated exterior cardboard as well as inner cartons, needed to be inspected upon arrival to verify ingredient statements and to check for damaged cardboard. Errors in these statements or damaged packaging would have stopped production and to get replacement packaging on short notice was beyond the capabilities of the railroad since this facility was not serviced by a class 1 railroad. Truck shipments appeared to be the only way to get replacement materials within 36 hours and to get the defective material removed quickly and back to the supplier.

Homogenized whole eggs, granulated sugar, flour and corn syrup were the major bulk ingredients that were brought into the facility in either stainless tanker trucks or center flow trailer trucks. Four 40K lb bulk egg tanks as well as six corn syrup and bulk flour tanks were housed inside the plant. Two ninety foot tall granulated sugar tanks were located outside the plant.

Posts: 347

Threads: 23

Joined: Sep 2011

It amaze me that those bulk products where not shipped by rail!!!!!

Posts: 255

Threads: 4

Joined: May 2010

kamerad47 Wrote:It amaze me that those bulk products where not shipped by rail!!!!!

Kamerad47,

Bulk eggs were shipped in stainless steel tankers from cracking plants in southern Indiana to our northern Michigan facility. These tankers were loaded at 32 degrees and would rise no more than two degrees in 30 hours with very few stops on the way. Attempting to load a large rail tanker and then get it moving north into Michigan and then uncoupled down state somewhere, then placed on a secondary railroad for the trip to the facility would take several hours longer. Also, the secondary railroad was headquartered fifty miles south of the Sara Lee plant.

Flour came primarily from mills in southern Michigan and corn syrup was off loaded from Class 1 rail tank cars, also in southern Michigan and pumped into stainless tankers and trucked up to the northern Michigan facility.

Posts: 180

Threads: 6

Joined: Feb 2013

Cheers guys

Looking like the cereal plant not going to work,going to have to have a re-think.

I'm happy with the track plan,just got to fit some industries to suit the freight cars i have,keep the imput coming.

Ray

Posts: 347

Threads: 23

Joined: Sep 2011

I understand what you saying But, 1 rail car = a least 4 truckloads ,bulk hauling is the RR game!!!! Trucking co's unload bulk tankers & tanker trailers !! They don't want to pay people to unload railcars??

Posts: 255

Threads: 4

Joined: May 2010

Corn syrup, flour and granulated sugar could have been shipped by rail, however bulk egg is a tricky item, due to it's nature. You have to realize it becomes a liability game in the event that contaminants are found in bulk items. Where did the contamination originate... from the supplier or from the tank car leasing company? This goes for both truck tankers as well as rail cars. Several smaller loads of bulk items are more manageable than a few large loads.

Posts: 2,269

Threads: 181

Joined: Dec 2008

fast car Wrote:Corn syrup, flour and granulated sugar could have been shipped by rail, however bulk egg is a tricky item, due to it's nature. You have to realize it becomes a liability game in the event that contaminants are found in bulk items. Where did the contamination originate... from the supplier or from the tank car leasing company? This goes for both truck tankers as well as rail cars. Several smaller loads of bulk items are more manageable than a few large loads.

Sounds like the solution is to have your own chickens and process your own eggs. Otherwise, outside contaminants will always be an issue no matter how it is transported.  But if the OP wants to use rail transport, he can easily do so, since your plant used to use it as proven by the existing rail spur which is still in place. Too many modelers end up talking themsleves out of the layout they really want because of "realism" issues.

But if the OP wants to use rail transport, he can easily do so, since your plant used to use it as proven by the existing rail spur which is still in place. Too many modelers end up talking themsleves out of the layout they really want because of "realism" issues.

Posts: 255

Threads: 4

Joined: May 2010

MountainMan Wrote:fast car Wrote:Corn syrup, flour and granulated sugar could have been shipped by rail, however bulk egg is a tricky item, due to it's nature. You have to realize it becomes a liability game in the event that contaminants are found in bulk items. Where did the contamination originate... from the supplier or from the tank car leasing company? This goes for both truck tankers as well as rail cars. Several smaller loads of bulk items are more manageable than a few large loads.

Sounds like the solution is to have your own chickens and process your own eggs. Otherwise, outside contaminants will always be an issue no matter how it is transported.

But if the OP wants to use rail transport, he can easily do so, since your plant used to use it as proven by the existing rail spur which is still in place. Too many modelers end up talking themsleves out of the layout they really want because of "realism" issues.

Outside contamination, whether it is introduced during the production process or in the making of the raw material itself, is and always will be an issue. We purchased pasteurized whole eggs and preceeded to repasteurize the eggs once they were in-house. It's a small price to pay for piece of mind. We went as far as to purchase our own frozen warehouse facilities and staff them with our employees to make sure there is accountability and everyone is reading from the same page.

I'm not really sure what was delivered to our plant by rail. It was probably used during the late 60's and all through the 70's. I started in 1984, retiring this last January, 2013 and it was never used while I was there.

Posts: 180

Threads: 6

Joined: Feb 2013

Still trying different track plans,i've found a box in the loft which i'd forgot about,it's full of 60' bulkheads and 72' centre beams,going to try and fit them into my plans,might have to be a industrial spur with a team track.

This is why i always allow myself time for planning,before i start the build,you can always change things on paper alot easier.

On another note what is the average size (height) of the"shoe box"type factories,are they made mainly of sheet metals siding on brick bases,or are there poured concrete slab construction??

Ray

Posts: 255

Threads: 4

Joined: May 2010

LIJ

I have been modeling a Miami theme similar to Lance Mindheim's. Most of my structures are of poured concrete sidewalls, between 3.0" and 3.5" in height. I suppose that the geographical location has a lot to do with whether it is block or poured concrete. Uninsulated concrete sidewalls are cooler. However, once they warm up, they hold heat.

![[Image: IMG_0044-2.jpg]](http://i136.photobucket.com/albums/q166/ROADMAN_2006/IMG_0044-2.jpg)

![[Image: Photo008.jpg]](http://i136.photobucket.com/albums/q166/ROADMAN_2006/Photo008.jpg)

![[Image: IMG_0031-2.jpg]](http://i136.photobucket.com/albums/q166/ROADMAN_2006/IMG_0031-2.jpg)

Posts: 1,291

Threads: 64

Joined: May 2011

This is why I suggested a chemical plant. Different commodities with different weights and densities. Reefers were also used for some chemicals so that they could maintain a constant temperature. If you have a chemical plant and a building supply (cement, sand, gravel, lumber, and all other sorts of building supply & hardware.

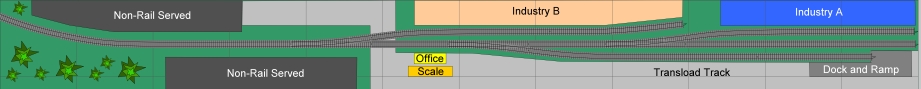

I redesigned your layout for 168 x 18 inches so that I could squeeze in another track:

![[Image: 8904334760_7d7e6b3493_o.jpg]](http://farm6.staticflickr.com/5469/8904334760_7d7e6b3493_o.jpg)

Mike Kieran

Port Able Lines

" If the world were perfect, it wouldn't be " - Yogi Berra.

Posts: 1,263

Threads: 45

Joined: Feb 2010

I think that Ray said he only had a length of 12ft (144in) available and Mike's plan is for 14ft. Even if Ray could add the the additional 2 feet, the switching lead is not long enough to be able to work the spurs comfortably. Even a very simple looking plan like this designed for Ray's available space (12ft x 14in) and using Peco No. 8 turnouts, would provide for a nice long switching session with an ample switching lead. Having two different main industries along with the transload track would take care of most all of Ray's equipment types.

The transload track could handle all sorts of cars: tank cars, covered hoppers of different types and commodities, box cars of various products, reefers if not used at one of the main structures and of course your bulkhead flats of lumber, wallboard, etc. The Centerbeams would be a problem as you must have access to both sides of the car, so in that case you might want to move the transload track closer to the edge to allow for access on both sides of the track; if necessary, move the main track a bit closer to the rear and reduce the depth of the two main industry structures.

For some ideas, I show some features on the transload such as the office and truck scale along with a dock and ramp at the end. Industries A and B can be whatever you find interesting and at least one of them should handle mostly box cars. The two non-rail served structures gives the plan the feel of your typical industrial spur.

Trying to find one large industry that would handle the majority of your equipment types is going to be a problem, as you've no doubt seen and a plan like this allows for more variety. You could of course change the industries from time to time as several folks have suggested and that would give you even more variety.

Ed

"Friends don't let friends build Timesavers"

|

![[Image: IMG_0044-2.jpg]](http://i136.photobucket.com/albums/q166/ROADMAN_2006/IMG_0044-2.jpg)

![[Image: Photo008.jpg]](http://i136.photobucket.com/albums/q166/ROADMAN_2006/Photo008.jpg)

![[Image: IMG_0031-2.jpg]](http://i136.photobucket.com/albums/q166/ROADMAN_2006/IMG_0031-2.jpg)

![[Image: 8904334760_7d7e6b3493_o.jpg]](http://farm6.staticflickr.com/5469/8904334760_7d7e6b3493_o.jpg)