Posts: 5,859

Threads: 175

Joined: Dec 2008

(01-02-2022, 10:12 PM)cnrglen Wrote: ...I have fitted the roofs to the cars but the side walls seem to have a warp to them so when the time comes, I'll be gluing and clamping things together to make the car straight. This was a bit disappointing as I had hoped to have the roofs removable.

You may be able to add some styrene crossmembers below the roof line, in order to re-straighten the sidewalls. If that's possible, the roofs should still be removeable.

I'm not overly familiar with these cars (I have a few), but when I have time, I'll open one up, and see what other options might be available.

Wayne

Posts: 883

Threads: 56

Joined: Mar 2015

That's a good idea. I think I'll look into that. I'm also going to check that I have all the windows pressed in completely. I noticed that if they are a bit out of the frame they can push against the seats and bow the walls out.

Posts: 883

Threads: 56

Joined: Mar 2015

Well, after fiddling with these two cars for the past week, trying to get them to run right, I've come to the conclusion that I won't be able to fix them. I ended up haveing to glue the roofs on because of the bowing. I even glued the styrene crossmembers and the roofs still wouldn't 'snap' into place like the instructions stated. And when I tried to run them on the layout, they consistently derailed on my 26" radius curve. I made the modification that Charlie suggested but that made no difference, the trucks still wouldn't rotate enough without hitting some of the underbody detail. I trimmed both the brake beams on the trucks and some of the brake rigging on the frame and still no go.

All I can say is, anyone what them?

Posts: 1,120

Threads: 84

Joined: Nov 2010

Posts: 883

Threads: 56

Joined: Mar 2015

Thank you for your advice. Armed with your and some others suggestions I performed some surgery on one of the cars.

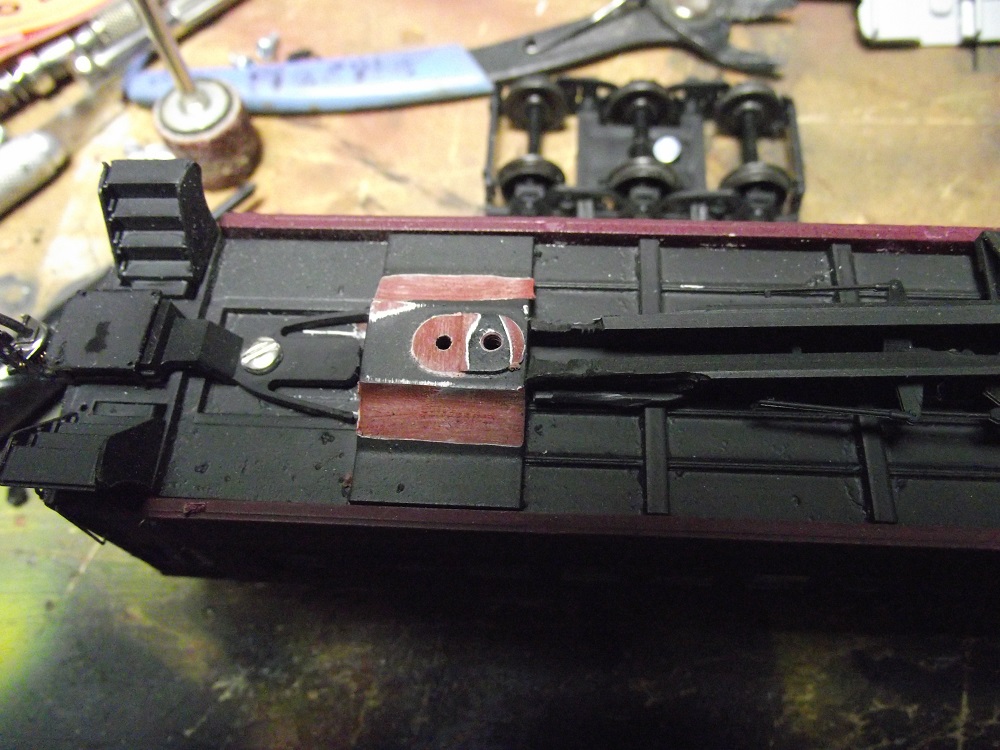

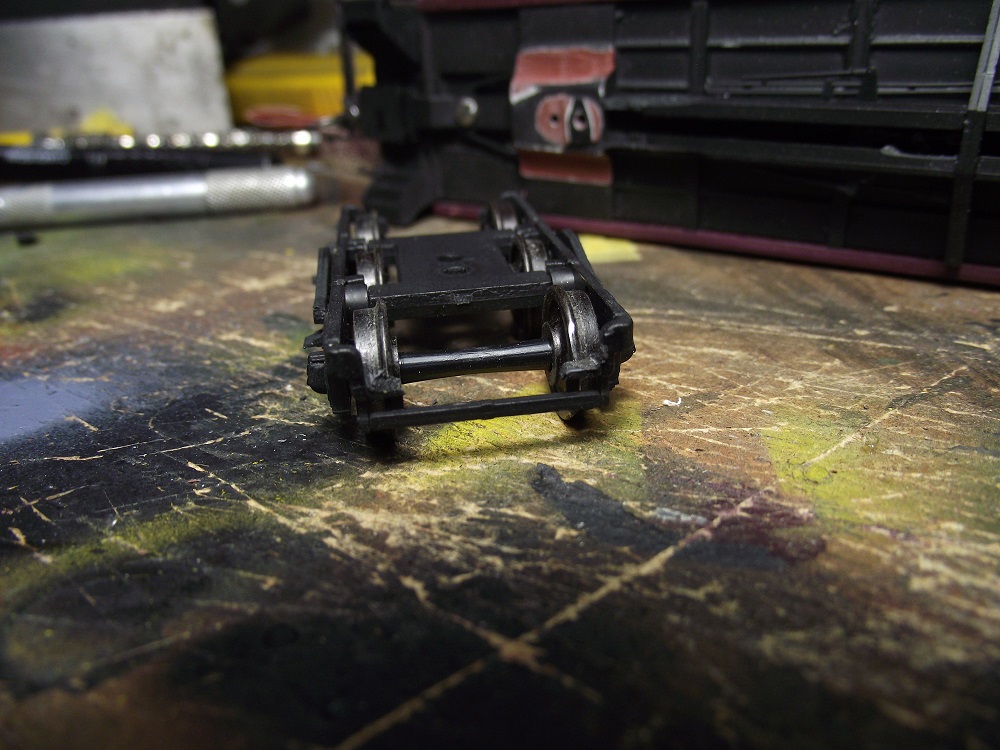

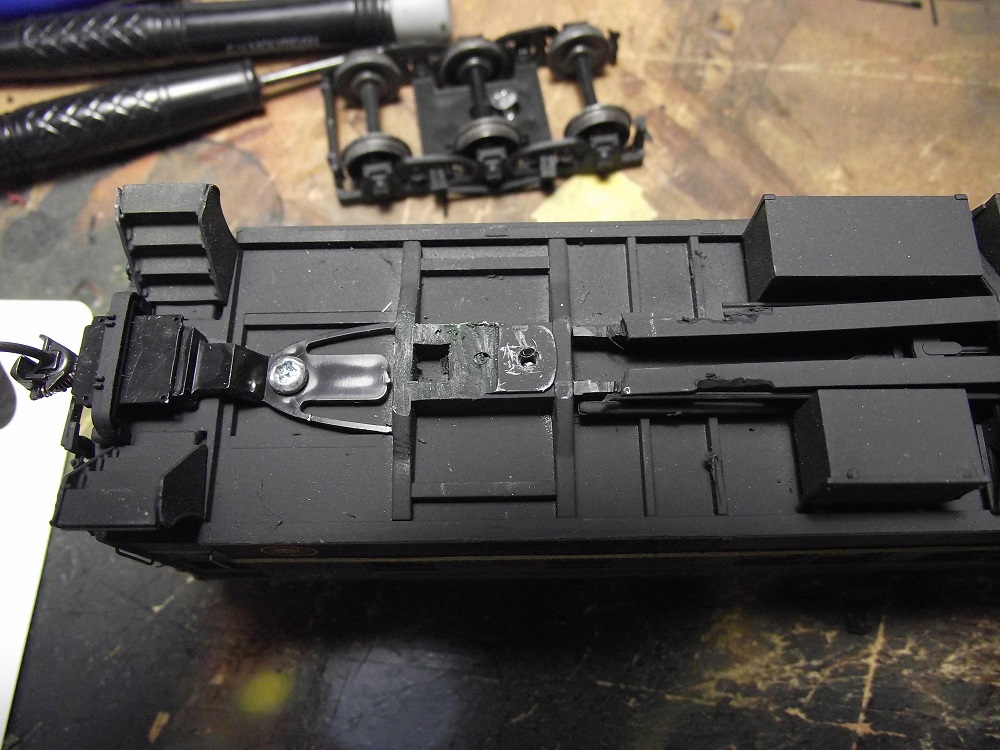

The center wheelset was hitting the bolster sides so I took my dremel sander and removed the material you see. I also cut the brake rigging back and sanded the center sills flat.

I also trimmed the brake beam like you did. After these mods, I found that the car could finally coast freely around the layout and the 26" curves.

My next step is to repeat the same procedure on the second car. I know the modifications look a bit extreme but once I repaint the areas and re-install the trucks it won't be that noticable.

After that I'll look into freeing up the coupler swing. I think I need to shorten the plastic 'springs' as they appear to be binding.

Posts: 883

Threads: 56

Joined: Mar 2015

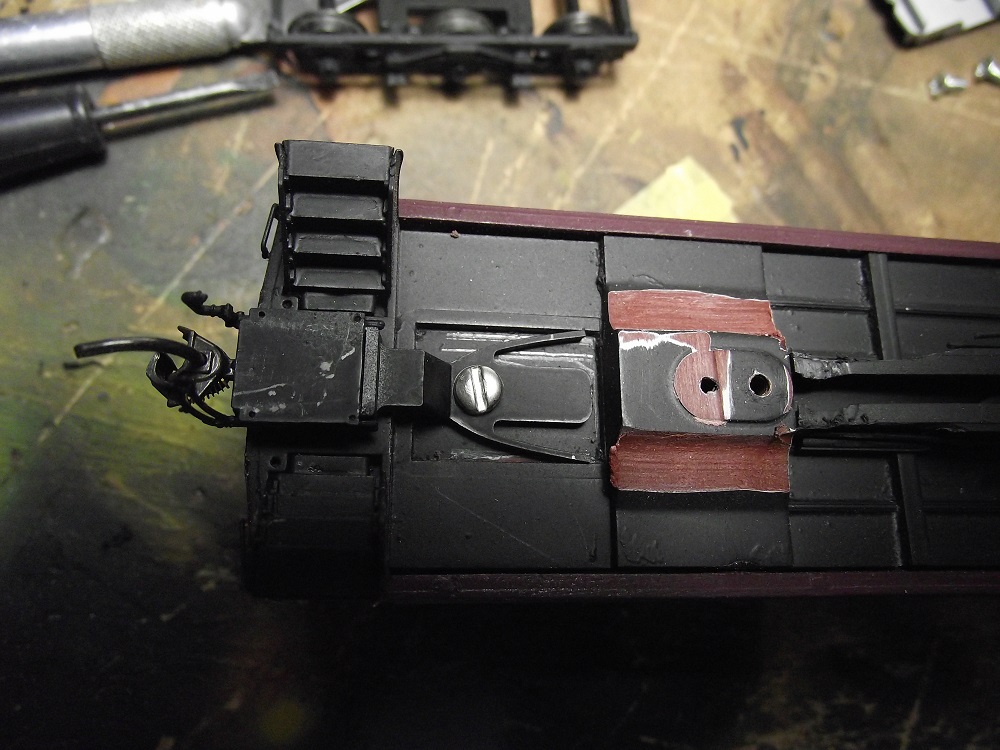

I modified the coupler box swing/spring mechanism slightly. I reamed out the mounting hole very slightly because it was too tight and causing a bind, then I shortened the plastic 'springs' by about 1/16".

I decided not to add the coupler yokes or coupler cut levers as they would interfere with the coupler swing on anything less than 28" radius curves. I'm also looking for replacement diaphragms as the branchline ones are too fragile and assembly looks too finicky.

I was going to make the same bolster modifications to my Branchline Pullman car.

But this one was better engineered so the bolster doesn't come into contact with the center wheels.

Now that the cars actually run, I'll be repainting the undersides and adding some touchups before a light weathering.

Posts: 883

Threads: 56

Joined: Mar 2015

I completed the two CP cars this week along with three freight cars that had been waiting their final airbrush weathering.

I just re-painted the areas that I had to grind away for the truck swing and touch up others that had some glue staining. After that I airbrushed some polly-s dirt on the undersides. I'm stating to run low on the Polly-s Dirt weather paint so I waited on the weathering for the three freight cars so I wouldn't waste paint.

I also want to take a moment to thank everyone who encouraged me and gave their advice on this fairly challenging project. These car would have not been completed without your help.

Posts: 9,709

Threads: 233

Joined: Dec 2008

Glen, as we rednecks from Ohio say. Ya done good.

Charlie

![[Image: dsc05286ytjqr.jpg]](https://abload.de/img/dsc05286ytjqr.jpg)

![[Image: dsc05287i0jl3.jpg]](https://abload.de/img/dsc05287i0jl3.jpg)

![[Image: dsc05288tfjru.jpg]](https://abload.de/img/dsc05288tfjru.jpg)

![[Image: dsc05289mwk9c.jpg]](https://abload.de/img/dsc05289mwk9c.jpg)

![[Image: dsc05290o6ksz.jpg]](https://abload.de/img/dsc05290o6ksz.jpg)