10-10-2016, 06:15 PM

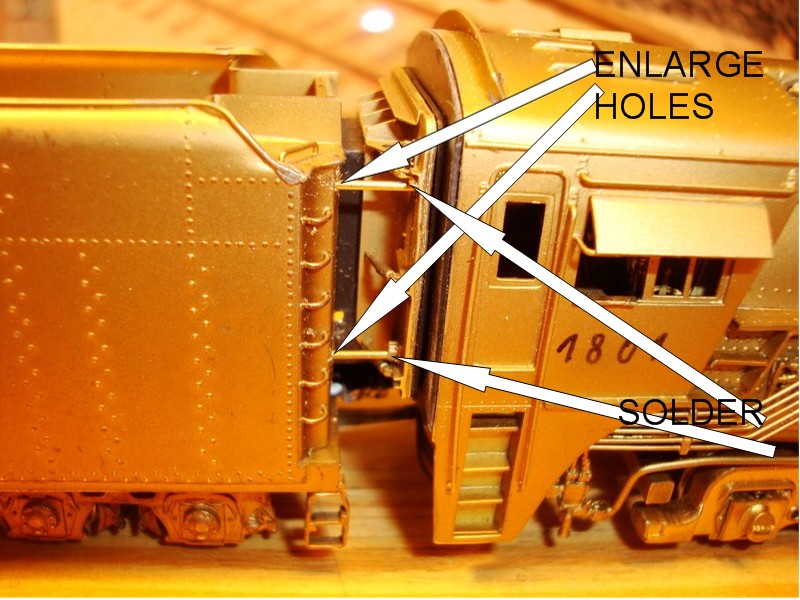

Perhaps I've misunderstood the set-up or misstated my suggestion: If the bent-over ends of the rods are supposed to remain in their countersunk positions, then simply cutting off the bent portion and soldering the rest to the brass plate at the front of the diaphragm should keep them in place. You could then enlarge the holes on the front of the tender itself to allow movement of the rods when the diaphragm pivots, as shown in the photo below. The black plastic plate could be cemented back into its original position:

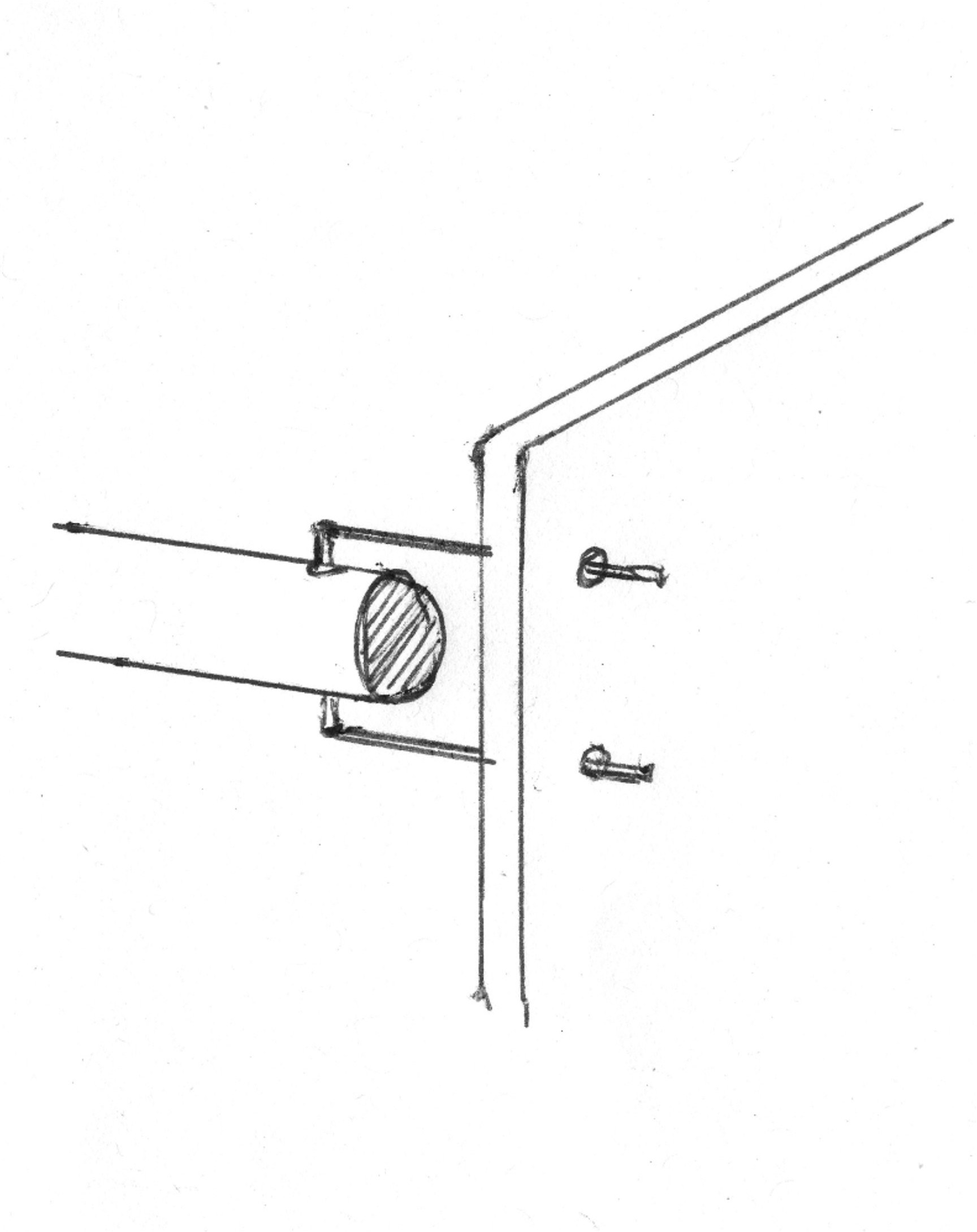

If you require more movement, drill-out the rods vertically near their ends, as illustrated below, then pass a phosphor bronze or stiff brass wire through each hole. Bend each wire into a tight "U"-shape, as, shown, then drill the brass plate to accept the free ends of the wire. Slip the wires through their matching holes in the brass plate, bend-over the protruding ends (leaving a little space between the end of each rod and the surface of the brass plate) and solder the wires to the brass plate. This will form a loose-fitting hinge at the front end of each rod.

A more elegant version could be had by adding a bracket above and below each rod on the rearward-facing side of the brass plate, and slipping the pivot wire through all three pieces and soldering the wire to each bracket.

Wayne

If you require more movement, drill-out the rods vertically near their ends, as illustrated below, then pass a phosphor bronze or stiff brass wire through each hole. Bend each wire into a tight "U"-shape, as, shown, then drill the brass plate to accept the free ends of the wire. Slip the wires through their matching holes in the brass plate, bend-over the protruding ends (leaving a little space between the end of each rod and the surface of the brass plate) and solder the wires to the brass plate. This will form a loose-fitting hinge at the front end of each rod.

A more elegant version could be had by adding a bracket above and below each rod on the rearward-facing side of the brass plate, and slipping the pivot wire through all three pieces and soldering the wire to each bracket.

Wayne