01-20-2013, 06:44 PM

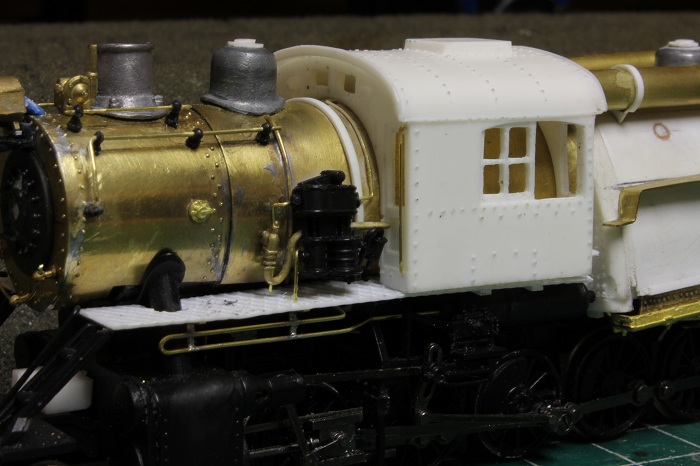

The next thing to do was the air and steam lines that feed in and out of the compressor. I got a drawing of the cross compound air pump piping from here. <!-- m --><a class="postlink" href="http://trainperson99.home.comcast.net/~trainperson99/brakes.html">http://trainperson99.home.comcast.net/~ ... rakes.html</a><!-- m --> They were formed out of some brass wire that scales out to about 1 1/4 inches in diameter. These pipes normally range from 1 1/8 to 1 1/2 inch so I felt that this was close enough.

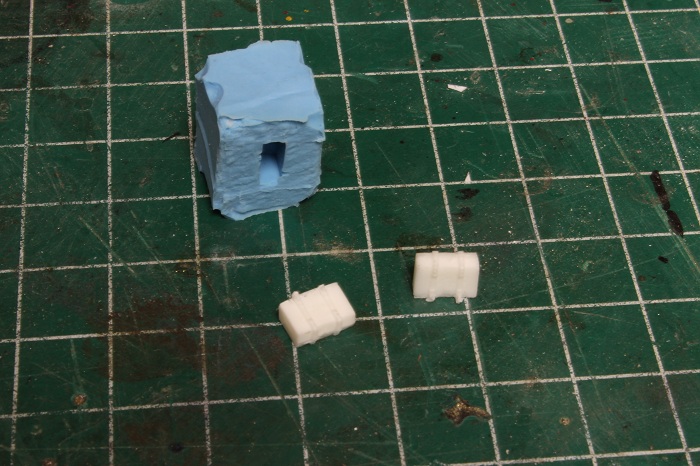

From there I moved on to a detail that was originally meant for my CNJ 2-8-0 that was featured in last June's issue of Railroad model craftsman but was not correct enough for the CNJ loco. But this is a freelanced model so it works just fine...I based the cab signal and train control system off of the CNJ's composite system of ATC speed & ATC stop. I'll go more into that later, but the box that I fabricated to hold the automatic train stop equipment on my 2-8-0 was too small, so it was rebuilt to the correct size. This left me with a unusable mold, or so I thought. I managed to find my old mold but not my master ...I built that by starting with an O scale suitcase, cutting off the handle, and adding hinges & straps to it from styrene. When I mixed up some resin I got this..

...I built that by starting with an O scale suitcase, cutting off the handle, and adding hinges & straps to it from styrene. When I mixed up some resin I got this..

it was the first time I used this mold and I was happy with the results. This cabinet was then placed on the pilot deck where it belongs.

it was the first time I used this mold and I was happy with the results. This cabinet was then placed on the pilot deck where it belongs.

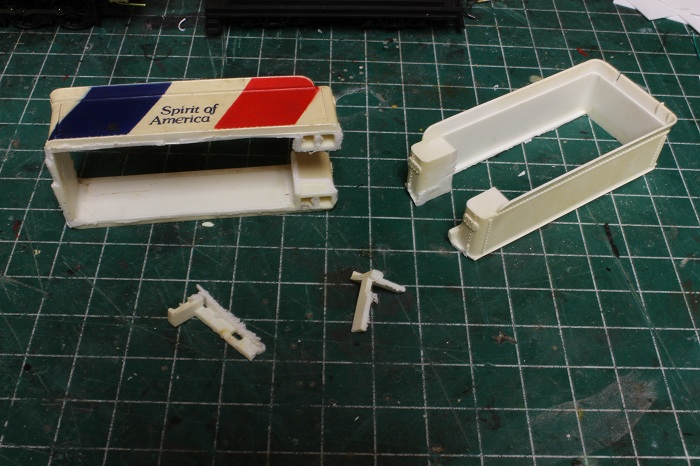

From there I moved on to the tender. I wanted to use an older style tender to emphasize that this loco was rebuilt several times over it's career, but retained it's original tender. I took some Tyco old time 2-6-0/4-8-0 tenders and rough cut off the parts that I didn't need. The tender frames will need to be shortened to fit the new cisterns, but that is work for another day.

I took some Tyco old time 2-6-0/4-8-0 tenders and rough cut off the parts that I didn't need. The tender frames will need to be shortened to fit the new cisterns, but that is work for another day.

From there I moved on to a detail that was originally meant for my CNJ 2-8-0 that was featured in last June's issue of Railroad model craftsman but was not correct enough for the CNJ loco. But this is a freelanced model so it works just fine...I based the cab signal and train control system off of the CNJ's composite system of ATC speed & ATC stop. I'll go more into that later, but the box that I fabricated to hold the automatic train stop equipment on my 2-8-0 was too small, so it was rebuilt to the correct size. This left me with a unusable mold, or so I thought. I managed to find my old mold but not my master

...I built that by starting with an O scale suitcase, cutting off the handle, and adding hinges & straps to it from styrene. When I mixed up some resin I got this..

...I built that by starting with an O scale suitcase, cutting off the handle, and adding hinges & straps to it from styrene. When I mixed up some resin I got this..

From there I moved on to the tender. I wanted to use an older style tender to emphasize that this loco was rebuilt several times over it's career, but retained it's original tender.

My other car is a locomotive, ARHS restoration crew