10-08-2017, 02:48 PM

Thanks Gents.

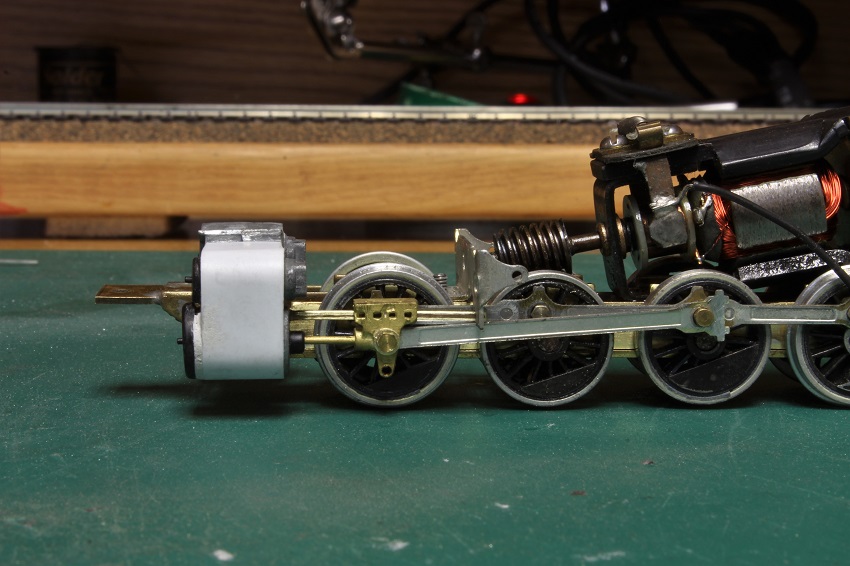

I did check my brass frame for bad solder joints after reading your post Twilight, and all seems good. It was able to withstand the force of me twisting the front portion back into alignment with out any failures. Thanks for the heads up . I also checked the h-9 frame against my brass one and they are extremely similar. The main difference between the two is in the drive, and that lies in the crosshead and guides.

. I also checked the h-9 frame against my brass one and they are extremely similar. The main difference between the two is in the drive, and that lies in the crosshead and guides.

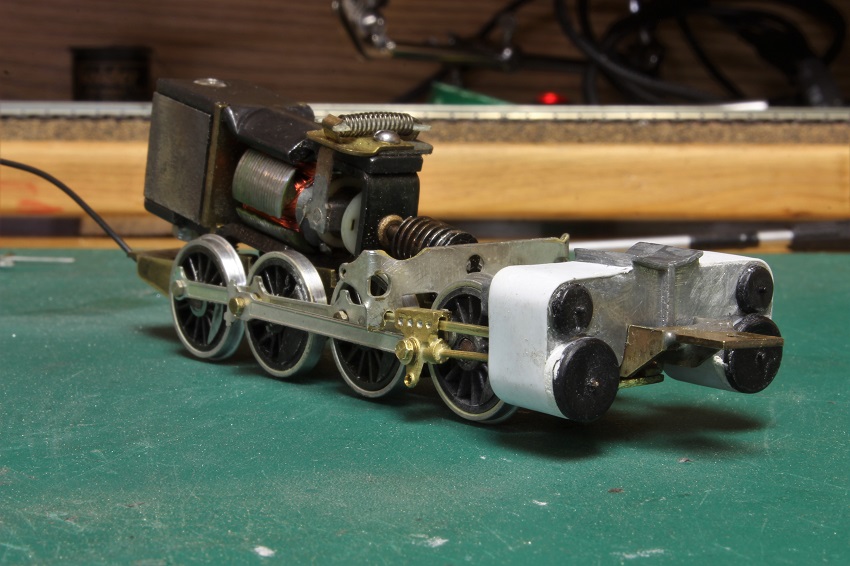

Now some more work on the cylinders. I removed the cylinder and valve covers from B-man plastic castings and attached to the Bowser castings.

A wrapper was also added around the outer edge to give them a closer profile to the Reading cylinders. I did notice the Bowser cylinder casting should be just a touch wider than it is. I may have to do some creative bending to the valve gear to keep them from binding against the side rods.

This crosshead is not lining up on the guide as nice as it should on this side. This will need some work.

You will also notice that I added another feature from the plastic castings. It's a small tube that extends out from where the piston enters the cylinder. I added this as the pistons are just a tad bit too short. Every few revolutions it will pop out of the hole in the cylinder when the main rods are at far end of their stroke.

I did check my brass frame for bad solder joints after reading your post Twilight, and all seems good. It was able to withstand the force of me twisting the front portion back into alignment with out any failures. Thanks for the heads up

. I also checked the h-9 frame against my brass one and they are extremely similar. The main difference between the two is in the drive, and that lies in the crosshead and guides.

. I also checked the h-9 frame against my brass one and they are extremely similar. The main difference between the two is in the drive, and that lies in the crosshead and guides. Now some more work on the cylinders. I removed the cylinder and valve covers from B-man plastic castings and attached to the Bowser castings.

A wrapper was also added around the outer edge to give them a closer profile to the Reading cylinders. I did notice the Bowser cylinder casting should be just a touch wider than it is. I may have to do some creative bending to the valve gear to keep them from binding against the side rods.

This crosshead is not lining up on the guide as nice as it should on this side. This will need some work.

You will also notice that I added another feature from the plastic castings. It's a small tube that extends out from where the piston enters the cylinder. I added this as the pistons are just a tad bit too short. Every few revolutions it will pop out of the hole in the cylinder when the main rods are at far end of their stroke.

My other car is a locomotive, ARHS restoration crew