Posts: 1,797

Threads: 81

Joined: Dec 2008

Steamtrains Wrote:The "P" word is forbidden.....We WORK when we do the train thing.....Although that might just apply if there is a wife around....

Yes of course. I was looking for the right word when I posted that comment. Please pardon my transgression. I cannot wait to get home and pl ....I mean work with my trains tonight.

Posts: 1,999

Threads: 98

Joined: Dec 2008

tetters Wrote:Steamtrains Wrote:The "P" word is forbidden.....We WORK when we do the train thing.....Although that might just apply if there is a wife around....

Yes of course. I was looking for the right word when I posted that comment. Please pardon my transgression. I cannot wait to get home and pl ....I mean work with my trains tonight.

"Operate my railroad! empire"...Thats what I tell everyone........

Torrington, Ct.

NARA Member #87

I went to my Happy Place, but it was closed for renovations.

Posts: 446

Threads: 23

Joined: Mar 2009

Steamtrains Wrote:The "P" word is forbidden.....We WORK when we do the train thing.....Although that might just apply if there is a wife around....

Today I was working on my train layout. Everything didn't go right. I rambled on about whatever. I was building a wood inclosure for my control panel, with a hinged cover for access to the wireing. The wood enclosure is done! It came out good. My wife who always gives me a hard time, continued to do so. The "P" word and "W" word has no meaning to her. Giveing me a hard time is what she lives for. Please forgive me for using the "P" word when I was "P"ing. For when I used it, I was truely was "P"ing.

frank

" It's a Heck of a Day " !!!!

Posts: 446

Threads: 23

Joined: Mar 2009

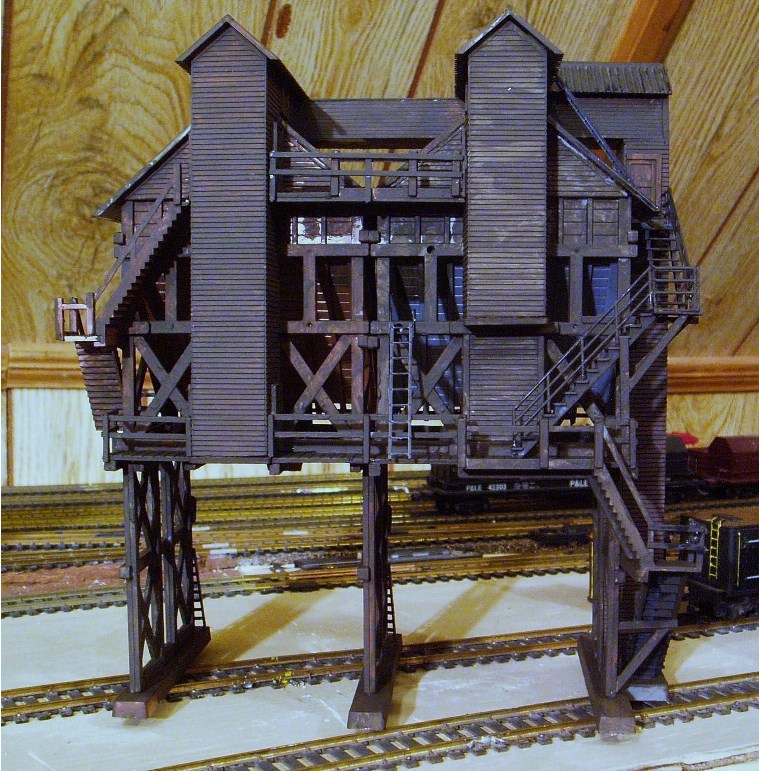

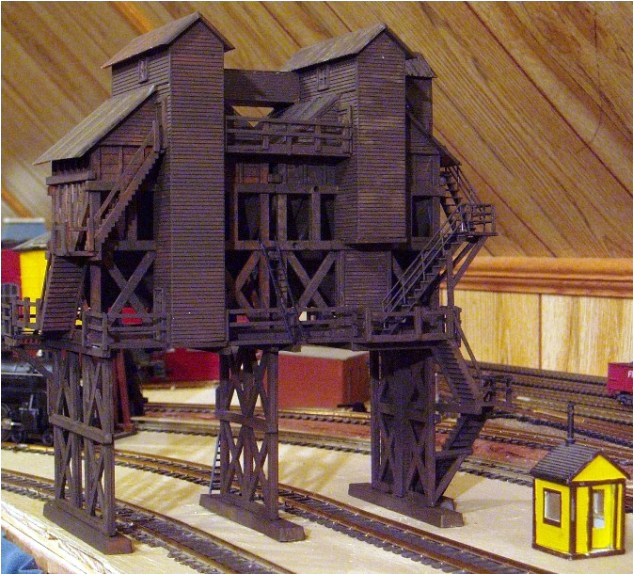

I had a need for a coaling tower that would service two tracks. All I had was Bachmann ( old Plasticville ) coaling towers. They get loaded from underneath and load to the side. For me this won't work. The basic idea was to cut the coal bin area free of the tower support legs. Then just put the legs back where I want them. It sounds easy. but their was alot more to it than that. A realistic way was needed to get the coal up to both bins. A third coal tower was needed to supply the chain and bucket lift housing to the upper conveyer belt that would deliver the coal to the two towers. This conveyer belt has to pass thro both bins. It needs to unload the coal onto another shorter conveyer belt which brings the coal to the top of the slide in each bin. Ok now I realize what would be necessary for this coal tower to be realistic. I'm not building the interior working parts. Just the housings that they would to in. I must have access to these conveyer belts, deflectors and slides to maintain them. Here is what I kitbashed.

First what a Bachmann coal tower looks like.

Next the tower completed in place with locos being serviced.

A photo of the entrance side.

" It's a Heck of a Day " !!!!

Posts: 2,959

Threads: 158

Joined: Dec 2008

I really like that kitbash! I also like all those old vintage steamers - mostly mantua?

--

Kevin

Check out my Shapeways creations!

3-d printed items in HO/HOn3 and more!

<!-- m --><a class="postlink" href="https://www.shapeways.com/shops/kevin-s-model-train-detail-parts">https://www.shapeways.com/shops/kevin-s ... tail-parts</a><!-- m -->

Posts: 446

Threads: 23

Joined: Mar 2009

A inspection tour of the twin coal Towers

In this photo of the rear of the coal towers you can see to the lower right the access stairway from ground level. Take this up to the first platform. Go the door on the left. Enter. This is the furthest out tower ladder access shaft to the top of the tower. The furthest out name is from the fact that coal is delivered first to the nearest tower to the coal raising device, then to the tower furthest from the coal raising device. So we have a near and far tower. Take the ladder up to the first platform with doors. There is a door to the left and one to the right. A ladder continues up from here. We take the door on the left. It goes outside the tower. a stairway goes down to a small platform and a second stairway goes further down to a platform bringing us around the side of the tower to the front platform. It is a short one and goes only to the coal shoot for the far tower. You can inspect the coal release door here. Its cable goes down lower to where a man on top of the tender can reach it to pull and release the coal to the shoot and down to the tender coal bin. Everything look OK here! Now to your right is a ladder up to a higher platform. Climb up to this platform. We see a ladder going up and one going down. We also see the cable and counter weight system for raising and lowering the coal shoots. The nearest is for this tower and the farthest for the other .Inspecting each proves them to be in good order. This platform crosses over to the opposite tower. Climbing down brings me to a small platform where the coal release door can be inspected. Finding this OK, we return to the upper platform. Now we go to the ladder going down. This ladder go to the platform between the coal shoots. This platform is only used for working on the coal shoots. Going over to the ladder going up, we take it up. Here we see the roofs over the two towers. On this end is the enclosure for the main conveyor belt that brings coal to the far tower. Now knowing the layout of these tower ladders, and platforms I know to climb up to the roof and pass under the conveyer enclosure walking to the far end and step down to the platform. Here I am between the two towers. A door to my left and one to my right. I go to the right and thro the door. here I am back on that platform with the door opposite me now that I took down to the front outside platform and the coal shoots. We are done there. Now I take the ladder up. At the top is the delivery end of this towers small conveyer belt. I see and inspect the end roller it pillow block bearings and belt tracking adjustments. I check the belt to see that it is tracking properly, centered on it rollers. Looking down I see the tower slide, and the coal that is in this tower. Back down to the platform and out the door onto the platform between the towers I cross over to the opposite door, enter and see the ladder up to this the near towers conveyer belt and slide. I go up and do my inspection. Back down to the platform, out the door, cross over to the far tower and down the ladder to and thro the tower entrance door to the platform outside. walking away from the door to the stairs going up, I take them up to a door at the top of the coal raising enclosure. looking to my left down the main conveyer, I see that the deflector is in place to load the near towers bin. Operating the local control for the deflector I watching it withdraw and extend. I use the local control for the coal raising equipment and watch it all operate. Coal comes up from below on to the main belt and heads for the deflector.I have put some coal on the main conveyer. belt.. Because the deflector is extended running the coal raiser runs the main belt and the near tower belt. I operate only the main conveyer and near tower belt to off load the coal into the near tower. Everything is running fine. It was a good test run. Now i withdraw the deflector. I run the main belt. Automatically the far tower belt also run. Everything is working right. I replace the deflector the way I found it put all switches back to remote control and off I go back down the tower. My inspection over.

" It's a Heck of a Day " !!!!

Posts: 446

Threads: 23

Joined: Mar 2009

Electrical operation

Olear Wapner coal tower.

**This 1926 version of our model CT1926T is shown here. This tower is available in single bin ( CT1926S),a twin bin as shown, and a triple bin (CT1926T). Special orders for towers with more bins can be made. Inquiries for this can be sent to our home office.

**The electrical operation for all our coal towers is basically the same. We use 3 phase 208 volt as the operating voltage supplied to all our towers. All large drive motors on our chain and bucket coal lifting tower, conveyer belts, and coal deflectors are 3 phase 208 volt. Single phase 110 volt is for the electrical control panel, coal shoot operating motor, coal release motor, and all lighting. Of course to prevent employee theft of light bulbs all fixtures are left hand threaded.

**When a locomotive engineer wishes to load his tender bin he must wait for a green light. Upon getting the green light he may proceed to where his fireman directs him to advance to. The fireman can now go to the shoot control switch below and to the right of the control light fixture, also a second is above on the platform by the coal shoot. From here he can lower the coal shoot above the tender bin. It can be reached from the ladder. The coal shoot can easily be seen from the upper part of the ladder. Or from a position of advantage on the upper platform. Once the shoot starts to move down the control light should turn to red. This tells the locomotive engineer not to move the locomotive.

**Now to release the coal to the shoot. This can be done two ways. The release rope hanging above the tender can be operated from either a high point on the tender or from the walkway above. We suggest use of the walkway location. The tender bin can be completely viewed from this location. The fireman can now operate the coal release and fill the tender bin.

**Once filled the fireman can use a second shoot lift control switch which is located on this platform on the wall by the ladder. When the shoot is all the way up and motion of the shoot has stopped, The control light will turn from red to green signaling that it is OK to move the locomotive. Once the fireman has resumed his position in the cab the engineer can relocate the locomotive clear of the tower.

***Instruction is finished. ****

" It's a Heck of a Day " !!!!

Posts: 1,797

Threads: 81

Joined: Dec 2008

toptrain Wrote:Of course to prevent employee theft of light bulbs all fixtures are left hand threaded.

Man I hate it when they do that!

Posts: 2,269

Threads: 181

Joined: Dec 2008

Me too, because it also means no one ever replaces burned out bulbs!

Posts: 446

Threads: 23

Joined: Mar 2009

Hey guys,don't blame me for that post. Those little people are takeing over. The Supervisor in charge of the maintance is loosing his grain of dust mind. He's using the internet to train, his little train people. When I leave the computer on and walk away for awile. Those little people start publishing blogs. They published a inspection tour and operational info for the coaling tower. Sneake little guys.

frank

" It's a Heck of a Day " !!!!

Posts: 2,269

Threads: 181

Joined: Dec 2008

Just hope they don't hold a meeting and decide to operate under new management!

Posts: 4,161

Threads: 174

Joined: Dec 2008

That's an excellent bash!!!! Nicely done!!!

Ralph

Posts: 446

Threads: 23

Joined: Mar 2009

The coal tower

tower front

tower rear

tower entrance side

" It's a Heck of a Day " !!!!

Posts: 1,797

Threads: 81

Joined: Dec 2008

That really is a fabulous looking structure. Nicely done!

Posts: 2,458

Threads: 57

Joined: Dec 2008

That's a great looking tower..!! I wouldn't even begin thinking about putting something that complex together...I'd be stompin' on it after a few days' time...

Gus (LC&P).