Posts: 3,683

Threads: 118

Joined: Jan 2009

I picked up the "thru-the-wall" sleeve for the air conditioner today. I'll get it put in this weekend and finish the sheetrock that has been left out because of the sleeve. Then I'll hire a finisher and hopefully will be done in a week or so.

Bending the shelf rails wasn't all that bad. Back on the "old Gauge" we had quite the discussion of how to level the brackets/benchwork - from shims to leveling bolts installed in the brackets to grinding the brackets a bit at the rail/bracket junction to just making the benchwork dimensions in the front a little less than in the back. Then I discovered the "brute force" method and used that.

Three Foot Rule In Effect At All Times

Posts: 2,423

Threads: 63

Joined: Dec 2008

Ocali:

I just built 2 of the Bullfrogs; now I need to figure out what I was going to do with them.

They are a very fast assembly: laser cut wood that glues and screws together. Go slowly with the first one until you see the pattern. Tabs may need a bit of filing.

They also sell a rod for activating it. This is 2 pieces of plastic tube plus some fittings. warning: do not glue the knob together until you reach final installation.

There is another outfit selling a similar device in blue plastic. They also sell an activating rod that looks like FastTracks but has different hardware. I like bits of both.

David

Moderato ma non troppo

Perth & Exeter Railway Company

Esquesing & Chinguacousy Radial Railway

In model railroading, there are between six and two hundred ways of performing a given task.

Most modellers can get two of them to work.

Posts: 1,229

Threads: 23

Joined: Dec 2008

BR60103 Wrote:Ocali:

I just built 2 of the Bullfrogs; now I need to figure out what I was going to do with them.

They are a very fast assembly: laser cut wood that glues and screws together. Go slowly with the first one until you see the pattern. Tabs may need a bit of filing.

They also sell a rod for activating it. This is 2 pieces of plastic tube plus some fittings. warning: do not glue the knob together until you reach final installation.

There is another outfit selling a similar device in blue plastic. They also sell an activating rod that looks like FastTracks but has different hardware. I like bits of both.

I have heard of the blue one (blue point...right?) but have not looked into it yet. I'll have to take a look before I reach that stage.

Spent some time tonight cleaning up the garage in preparation for beginning the benchwork. I have printed out a copy of each section and overlayed both the bracket locations and the framing dimensions/locations in different colored inks. I know it won't be long before trains are running! (A few months at most, I hope).

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 2,423

Threads: 63

Joined: Dec 2008

Just one more point: the BullFrog has an SPDT microswitch while the blue one looks to have a DPDT switch.

BullFrog comes either as a kit or built up; blue point I've only seen built up. (kit is about half price).

David

Moderato ma non troppo

Perth & Exeter Railway Company

Esquesing & Chinguacousy Radial Railway

In model railroading, there are between six and two hundred ways of performing a given task.

Most modellers can get two of them to work.

Posts: 1,229

Threads: 23

Joined: Dec 2008

If you've never read it, I highly recommend borrowing or purchasing your own copy of Iain Rice's "Mid-Sized and Managable" Layout designs book. In general it's good reading whether or not you're planning or building a layout. In particular, the section about finances, time and family involvement are well said and important to consider ideas especially if you are building or planning a layout.

That said, I've done some budgeting of my own (both time and money) regarding my current layout project. Holiday gift cards and a small surplus of cash enabled me to purchase the necessary shelving parts and framing lumber for benchwork. That, along with the track lighting units we already have should give me plenty to do while saving the monthly stipend (mad money) for track and related componants.

I will need to purchase flex-track and turnouts, plus turnout control mechanisms, and MRC DCC sockets for each side (along with another throttle, eventually). When I budget this and run it out over time, well, it's not looking good for moving too quickly.

There is a possibility of running into some additional funds if MRH online magazine buys the article I'm preparing, as mentioned above, but that's still in the works.

In the mean time, I'll keep plugging along with the spring contest and working on benchwork. You'll see the progress as it happens...only that may be a bit farther between than I'd originally hoped.

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 1,229

Threads: 23

Joined: Dec 2008

Howdy, folks! Glad to be posting on this topic again...that means progress, people!

Here are the latest photos:

[albumimg]2414[/albumimg]

[albumimg]2415[/albumimg]

[albumimg]2416[/albumimg]

This is the framework for side 'A', the rural scene. Took me a couple hours, I guess, working mostly by myself. It won't be resting here for long, though, as I will be taking it back down to the garage to use it to mark out the dimensions for the plywood top. That's right, butt joint construction with a tabletop.

NO L-girders with risers here. This, I believe, is cheaper by far and the more useful choice for this layout. L-girder has it's place, granted, but in this case basic box frame and ply construction will suffice and be far simpler. At the risk of being labled a luddite, I even cut the lumber with a hand saw  hock: but I did use a power drill for assembly.

I may cut a little stream bed into the ply and framing at some point, and perhaps add a brace when I do, but for now it'll be a solid top. Most of the scenery will be at or above grade so there's no need for any serious dips or depressions. The 'bridge' section across the room will include some actual below-grade scenery.

It's not level at present, either, as you can see by the third picture where the framing does not rest on the short brace. I will be adding shims between the rear member and shelf brackets, at some point. I may lay track before then...we'll see. Part of the benefit of this construction is being able to take it off the shelf and lay it on the floor to work on it.

Tomorrow is supposed to be beautiful, just like today, so I may not get to begin work on side 'B'. Also, I have not purchased lumber for the connecting bridges between each side, although I may use leftover ply for one of them. We'll see. One of my LHSs is having a 'retirement' sale so I picked up a bundle of micro-engineering flex track and two Atlas code 83 custom line turnouts (a L and R each, both #4's).

I'll be posting again soon, hopefully, with a revised track plan. Instead of a complete double track main, I may be making it single track across the 'bridge' section spanning the room. I've always liked the idea of one train waiting in the hole for the other. A simple operational concept, but very prototypical, and can really add more interest to a layout....trains taking turns rather than both making laps.

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 3,683

Threads: 118

Joined: Jan 2009

Galen, that is looking very professional. I agree with your assessment of the L-girders. What you have there will be plenty strong, and a big plus as you mentioned is being able to remove the "shelf" to work on it at a different location. You mentioned cutting a stream bed... that is why I like 2" foam on top of the shelf. Makes it easy to cut ditches and make minor elevation changes.

Three Foot Rule In Effect At All Times

Posts: 1,229

Threads: 23

Joined: Dec 2008

Gary S Wrote:Galen, that is looking very professional. I agree with your assessment of the L-girders. What you have there will be plenty strong, and a big plus as you mentioned is being able to remove the "shelf" to work on it at a different location. You mentioned cutting a stream bed... that is why I like 2" foam on top of the shelf. Makes it easy to cut ditches and make minor elevation changes.

Thanks, Gary. I'll be adding a layer of fiber board on top of the ply, just under the trackwork. Not sure if I'll use it as roadbed or add a layer of N-scale cork as actual roadbed. I may use the cork under the main line and leave it out under the sidings. We'll see when I get to that stage. I'll be using plenty of foam for scenery. At this layout height it won't take much to screen a train from view...which has got me thinking more about a staging track or two... :geek:

As I mentioned in an earlier post, unless I receive a sudden windfall of hobby cash, this will be a slow and steady process. That's fine since there's plenty to do (like lighting) that won't cost anything since I already have it. I've already got the lumber for the other side of the room as well. I am very thankful that I have a regular hobby stipend as part of the family budget (well, it's mad money to spend however I like, I just choose to spend it on trains, usually!)

All that to say, don't look for any major updates (beyond more benchwork) any time too soon... :| In the mean time, I'm helping my 5 year old convert all of his (nee mine) N scale equipment from rapido to knuckle couplers. This too is a slow and steady process but so very worthwhile. It's all part of the evolution from toddler with toy trains to kiddo with model trains.

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 1,229

Threads: 23

Joined: Dec 2008

I should add, also, that this is the longest single section of benchwork I'll have to make. The other side will be in two sections, each 5' long or so, that will be bolted together and probably not undone unless absolutely necessary.

There was a great article in an issue of Model Railroader back in the 60's by Bruce Chubb about his Sunset Valley back in the early days. He constructed it in very much the same way for several years. Basically it was planned in sections long before there was a basement home. Constructed at his father-in-law's home (who subsequently became a modeler himself) the sections were eventually 'assembled' in their more permanent location once the home was ready. Benchwork, track, and I think even some scenery was done before they were moved into place.

I'm not sure I'll be able to do that with these sections should we move, but we'll see. Hopefully we'll be in this house for a long time to come, at least until the kids are in high school or beyond.

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 1,897

Threads: 40

Joined: Dec 2008

It looks good, Galen. I think the only thing I would add to the frame would be to take some left over scraps of 1x3 or 1x4 what ever you are using and make some cleats to bolt solidly into the shelf brackets and the frame to make sure nothing moves if bumped or in case of earth quake, although I don't know if you are in an area with earth quake faults or not.

Posts: 1,229

Threads: 23

Joined: Dec 2008

Russ - if we have any serious quakes it means the mountain (Rainier) is waking up! In that case, I'm not sure what'd become of the layout, our house, neighborhood, etc. We may be above any mud flows but would still be in range of pyroclastic flows, possibly, or shock waves from the explosion. That's assuming it erupts to the NW...hopefully it'll blow to the south when it does, and I believe it's long overdue, geologically.

I will be driving a couple screws up through holes in the brackets once the major construction is complete and the leveling finished. Of course, track will be laid by then, so it's still a ways off. For now it's just resting comfortably on the brackets.

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 335

Threads: 27

Joined: Dec 2008

ocalicreek Wrote:NO L-girders with risers here. This, I believe, is cheaper by far and the more useful choice for this layout. L-girder has it's place, granted, but in this case basic box frame and ply construction will suffice and be far simpler. At the risk of being labled a luddite, I even cut the lumber with a hand saw  hock: but I did use a power drill for assembly. hock: but I did use a power drill for assembly.

Hi Galen;

Two comments - first, your hand cut timber is impressive! I can get a nice cut on occasion with a handsaw, but invariably, the dimension is wrong. If the dimension is right, the cut isn't straight. This is one of those things where repetition (i.e. practice) makes a big difference.

Second is more general. I used L-girder on parts of the layout that I recently disassembled (197 Track Nails thread), and really liked the flexibility. But it's a very deep system - even without risers, mine was about 7 inches deep; 1x4 girders, 1x2 (on side) for the L part of the girder and 1x3 joists on top of that. I'll be exploring a more compact system for the coming layout, and a grid like yours is one of the ideas I'm considering.

Matt

Matt Goodman

Columbus, Ohio

Posts: 1,229

Threads: 23

Joined: Dec 2008

Matt - you're right, L-girder is tall! I believe it can be a useful system, as I've seen on many layouts in person and online, when the best use is made of the flexibility. Box frame or butt joint takes a bit more planning, perhaps, so that you don't put a turnout throw over a cross brace, whereas with L girder you just move a joist as necessary to avoid such things.

What frustrates me about L-girder, although not necessarily the system itself, is how it's used in the construction of beginner layouts. A Kalmbach video from the 80's with Wayne Wesolowski shows how to build a 4'x6' beginner layout using L-girder. They do a great job assembling girders and leg units, then adding the joists across the girders. Finally they plunk a sheet of plywood down on the whole thing. WHAT? Why go to all the trouble of L girder construction if you're not going to use risers and cookie cutter roadbed in order to take full advantage of the depth?

Granted, they do cut a water feature into one side and need to shift a joist, but I get the impression this wasn't planned. The whole thing looks a little slap dash at first. But a table-top layout doesn't need L-girder. IMO, it will gain more strength from a box frame a la the good 'ole Atlas plan book method.

I'm going to be working on the track plan tonight, and will hopefully get something scanned and posted. My printer/scanner has been acting up so we'll see how much frustration I want to endure to get it done, or else I'll have to do it tomorrow at work.

As for the cutting, well, most modelers can use a scale rule and some even use a caliper to cut very precise lengths of scale lumber. Yet somehow we get into trouble cutting actual 1x4s. Go figure. Measure 10 cut 1.

Thanks for the good feedback!

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 1,229

Threads: 23

Joined: Dec 2008

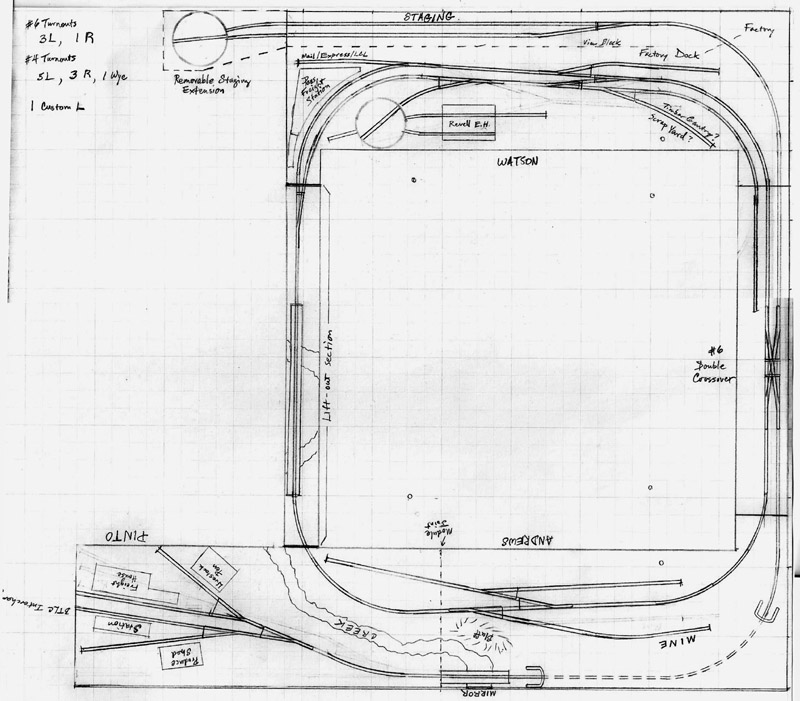

Here is the current (and hopefully final) plan for the bonus room shelf layout. There are things to adjust, of course, but I'd like to say this is 95% of the way there.

What sent me down this line of thinking was eliminating the double track main line loops. I mentioned before the interest generated when one train has to meet and pass another, vs. watching two circle endlessly. I went back and reread Frank Ellison's 'Art of Model Railroading' and sure enough, that's where I had seen that mentioned before.

Along those lines I began thinking also about making this a more specific branchline setting, operationally. The previous plan had no staging to speak of apart from a single hidden track. Adding a second was feasible, but why? The rest of the road didn't make sense with additional staging.

SO I set out to create a longer mainline run, as much as possible, without looping around too many times. I'm not a big fan of imagining distance by making laps. That just doesn't fly somehow. I'll allow other contrivances, but that one just stretches too far I guess.

Follow the route on the plan from Staging to Pinto, via Andrews and Watson. Staging is where this branch meets the mainline (or where this shortline meets the class one?). During 'op sessions' the double crossover is set to cross over. When I want to just let a train run I'll set it for the straight routes, but I won't need to constantly throw these turnouts during an operating session. It's as if it doesn't exist when operating 'normally', and is just a convenient way to route the main.

Trains travel from staging, [over the crossover], through the little mountain burg of Andrews, past the creek and over the bridge on the removable section to arrive in Watson. There the road engine is cut off and serviced. A smaller engine (most likely a tank engine or geared engine) breaks down the train and shoves the necessary cars [through the crossover], up a slight grade through the tunnel to the little town of Pinto. Here is the interchange connection with the Big Tujunga Lumber Company that provides a good bit of the traffic for the branchline.

Passenger service runs from staging to Watson and back, with express service and mail being switched out at Watson and forwarded on to Pinto daily. Passengers must disembark their short heavyweight coaches at Watson and board the antique open platform shorty cars for the trip to Pinto, if the volume warrants that. Otherwise it may be a special ride in Maggie, the drover's caboose!

I had thought about having the end of the branch be at Pinto, but I chose not to for a couple reasons. One was the lack of space at Pinto. Trying to squeeze in a turntable and runaround (I don't like turntables AS runarounds) and interchange with the BTLC and industries and some semblance of mountain scenery just wasn't happening no matter how hard I squeezed. Also the engine change at Watson allowed for more interesting operation as it created more jobs to do and a place to keep a couple locos on the layout. Had I kept the turntable at Pinto I would not have had any kind of engine shed or roundhouse, most likely.

I'll post more detailed pictures of each half of the layout with more explanation of each in a separate post.

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 1,229

Threads: 23

Joined: Dec 2008

The staging yard consternated me for some time, as I couldn't fathom a way to turn engines on the layout. Then it hit me and I thought, well, why not make a turntable (functional, not fancy) and have it fold down out of the way when not in use? So that's what I've drawn. It may not even be an actual turntable, but maybe an open fiddle yard with a loco cassette that you simply detach and slide around. It's not set in stone yet, but the concept is there.

Watson is named for my second son (middle name) and my wife's side of the family (grammy's maiden name). Watson will be a small urban outpost in the blue ridge mountains, more 'town' than city. The enginehouse is a Revell kit and will house the motive power for the run to Pinto and maybe a shifter for working the trains that arrive in Watson. There will be some sort of coaling facility, sand and water, of course and possibly the Woodland Scenics 'Caboose Sand and Coal' diorama that I built some time ago, for servicing the road's crummies (another task to add op fun).

The staging tracks will be hidden by a steep bank/retaining wall, common in appalachia, with the town on the (removable) hillside above. Where the staging track enters the visible layout, the track will pass between and beneath buildings in a factory complex. The bulk of the factory will be in the corner, with the loading zone on the short siding where it says 'factory dock'. This may be the 'Appalachian Confectioners Co.", makers of fine fudge, and assorted sweets.

There will be one other 'industrial' siding and it's a toss up between a scrap yard and a timber gantry. The long siding is for storing and sorting the cars to/from Pinto. This will be a shifting job to be done before the local freight arrives so that all the crew has to do is swap a cut out of the train for the one on the siding, then sort them before heading up the hill.

The turnout at the passenger depot will most likely have to be hand laid. It seemed a good place to squeeze in one more sure spot for express/baggage/lcl freight to give the switch crew more work to do when the passenger train is in town. The passenger job will most likely arrive behind either my Penn Line Atlantic or Aristo/New One 4-6-0, both high-drivered engines, and both in need of serious rebuilding.

Oh, and I decided to place the runaround turnout on the removable bridge section in order to gain good passing siding length. That turnout, plus three others all on this side, comprise the 4, #6 turnouts on the layout (besides the #6 double crossover, essentially one unit).

Up next, Andrews & Pinto.

Galen

I may not be a rivet counter, but I sure do like rivets!

|

hock: but I did use a power drill for assembly.

hock: but I did use a power drill for assembly.