Posts: 296

Threads: 24

Joined: Dec 2008

Well, if someone mentions that they "...finally found my BASTER !" next Thanksgiving, don't complain if the bird tastes a little strange !  Most impressed with your progress and results, so far...and continue to learn NEW stuff...thanks. Also (correct me, if necessary), FUTURE is very water resistant, when dry, but (IIRC) soluble by ammonia, (per the label instructions ?)...helpful for changes later. I never tried a "wetting agent" - alcohol, detergent, etc. - mixed with the Future, to combat the "floaties", as I used it only as a coating. Bob C.

James Thurber - "It is better to know some of the questions than all of the answers."

Posts: 612

Threads: 10

Joined: Feb 2011

Makes notes to "Avoid Bob's place and any basted roast turkeys, especially at Thanksgiving time".

I consume enough glues and solvents at work as it is without extra helpings.

Mark

Fake It till you Make It, then Fake It some More

Posts: 335

Threads: 27

Joined: Dec 2008

Bob C Wrote:Well, if someone mentions that they "...finally found my BASTER !" next Thanksgiving, don't complain if the bird tastes a little strange !

No, Bob, You're thinking too big...

Fluesheet Wrote:Otherwise, application is similar - I used a device whose name completely escapes me right now (plastic, functions like an eyedropper)

It finally came (returned?) to me last night - PIPETTE!  Thanksgiving is safe.

Fluesheet Wrote:Today I'll be wetted water and dilute white glue to another section for comparison - I'm curious if my issues and successes were due to my application method, or the adhesive used.

Wetting and white glue were more successful, though messier, or better put, wetter. I"m not giving up on the acrylic floor wax yet, but I'm reminded just how well the white glue method works.

Matt Goodman

Columbus, Ohio

Posts: 335

Threads: 27

Joined: Dec 2008

Wetting update:

Earlier, I wrote:

Fluesheet Wrote:Today I'll be trying wetted water and dilute white glue to another section for comparison - I'm curious if my issues and successes were due to my application method, or the adhesive used.

Neither the adhesive or wetting solution used are the issue with "wetting" Smith and Son's ballast - at least in areas where there is a lot of dust. Acrylic floor wax, alcohol and wet water all have equally difficult times wicking in. This is unfortunate, because the dusty areas do the best job simulating broken down cinder ballast.

A couple of modifications to the initial ballasting do help:

- Putting down a foundation of Woodland Scenics cinder, then adding Smith and Son's cinders on top or

- mixing WS and S&S cinder.

Both combinations drain liquids - and therefore wet - better than straight S&S ballast.

This image shows the mixed WS / S&S ballast:

![[Image: p660217084-4.jpg]](http://goodman312.zenfolio.com/img/v20/p660217084-4.jpg)

I've also found that adding the wetting solution or floor wax from the edges of the ballast and letting it wick into the center helps. Once the ballast shows signs of wetting between the rails, it's much easier to continue the wetting from the top. Hopefully that makes sense.

Adhesive update:

The acrylic floor wax is becoming my favorite adhesive from an application standpoint.

- It's "self wetting"

- Wetting / gluing is a one step process.

- No concerns about soaking surrounding materials during a wetting step.

- It sets very solidly

The disadvantage is it'll leave a bit of a shine if it gets on top of the ties (especially noticeable if only a portion of the tie is shiny - a shine is not noticeable in the ballast). I plan to kill that with a light airbrushing of dust.

But before I progress with the floor wax, I want to give Woodland Scenics Scenic Cement and diluted acrylic matte medium a try as an adhesive.

Matt Goodman

Columbus, Ohio

Posts: 335

Threads: 27

Joined: Dec 2008

In the prototype, ballast has to occasionally be cleaned so that it will continue to drain effectively. In the steam era (at least in the early thirties), the A.R.E.A. recommended that this be done anywhere from every year to once every eight years. If traffic was heavy, the ballast material was of a type that broke down easily and if the cargo dropped a lot of dust while in transit (such as coal loads), the frequency was on the short end.

For example, the A.R.E.A recommended the following cleaning schedule for stone ballast (considered the best ballast material):

- In terminal at intervals of one to three years

- In heavy traffic lines at intervals of three to five years

- In light traffic lines at intervals of five to eight years

Cleaning was becoming mechanized to some degree by the late twenties, but a lot remained manual. The manual process was to use pick and shovel to pull the ballast out between the ties down to a specified depth, then shake it through a ballast fork (like a pitch fork, but with narrower openings between the tines).

All of the above is background for a single photo...  Given the issues I've had with fouled ballast, I detailed two of the Preiser brothers to clean the worst spots. They are demonstrating the manual process here:

![[Image: p810708485-4.jpg]](http://goodman312.zenfolio.com/img/v20/p810708485-4.jpg)

Matt Goodman

Columbus, Ohio

Posts: 88

Threads: 1

Joined: Oct 2010

That rail joiner and fish plate detail looks really good! Your track info is very timely. I was just looking at a picture of some lonely worker in a terminal yard de-mucking between ties. Layout's looking great.

Posts: 3,262

Threads: 115

Joined: Dec 2008

Matt,Great job on the track..Looks like a urban industrial branch instead of a main line.

Larry

Engineman

Summerset Ry

Make Safety your first thought, Not your last! Safety First!

Posts: 1,797

Threads: 81

Joined: Dec 2008

That looks really awesome. Love the last photo, its a great detail to add.

Posts: 335

Threads: 27

Joined: Dec 2008

Thanks for the comments, guys. The ballast cleaning photo is my favorite posed photo so far. It turned out better up close than from my squinty-eyed paint-application distance of three feet! (how often does that happen?  )

Brakie, thanks for the industrial track compliment. I'm going to try to break the cinders down some more to give it a finer look. I'm trying to simulate something like this (although in the thirties, there would be more cinder and less vegetation in the right of way):

![[Image: p828676870-3.jpg]](http://goodman312.zenfolio.com/img/v16/p828676870-3.jpg)

Matt Goodman

Columbus, Ohio

Posts: 1,229

Threads: 23

Joined: Dec 2008

Something to consider - when I was watching a modern balast cleaning mechanized rail operation I was perplexed to discover that 'cleaned' balast actually looks dirtier than 'dirty' balast. The reason being is that rain washes grit and silt down from the rails & ties down through the balast to the bottom of the balast pile. The real danger of dirty balast is that it sets up hard like brick as that silt is compacted, heated, dried, etc. Silty soil, as anyone who has ever slipped on wet clay-soil ground knows, can be slippery. Balasted track resting on a hard-pan of silt can slide right off out of alignment or worse the next time a heavy train passes over after a good rain shower.

So after the balast is cleaned, it actually takes on a dirty look. All the silt and grit is stirred up (and in the case of the mechanized cleaning train removed and sent by conveyor into hopper cars) and becomes visible again until a few good rains wash it away again. I've never seen this modeled before, but most of our mainline balast looks way too 'dirty', that is, bright grey or white or pink without a hint of dust or grime other than locomotive drips. Sidings weren't cleaned as often as the mainline since speeds and loading was restricted.

Hope this helps,

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 335

Threads: 27

Joined: Dec 2008

Thanks for the comment Galen - good points all. Poor ballast or roadbed conditions could also lead to pumping ties - that would also be interesting to model.

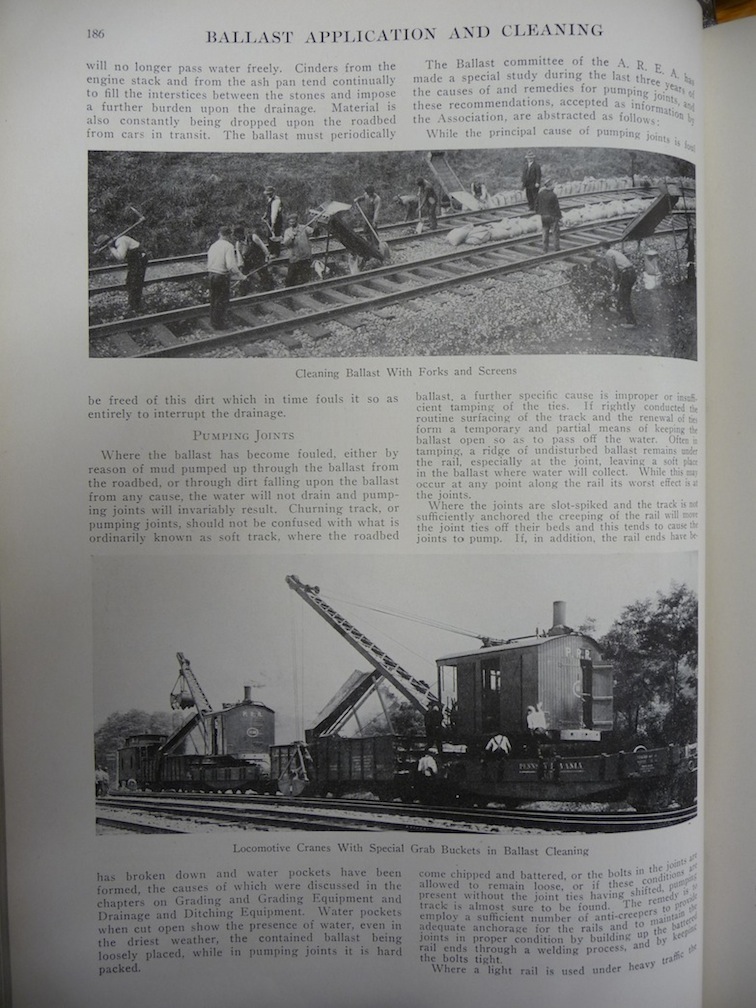

I'm getting some of my inspiration from a 1929 maintenance cyclopedia, which has some great photos of then-current maintenance tools and processes. I've attached a photo of one of the Cyclopedia's pages showing an example of manual ballast cleaning. The lower photo shows a much more mechanized operation, and there are other machines of various complexity pictured on subsequent pages. Pumping ties are described in the text.

Matt Goodman

Columbus, Ohio

Posts: 335

Threads: 27

Joined: Dec 2008

It's been awhile since I've posted, and there have been some changes.

First, a bit of scenery - static grass was pictured in an earlier post.

Here I was experimenting with getting some grass between the rails as in a little used spur. I used a static grass applicator and applied diluted white glue in a very targeted location. It worked, but I don't care for the look; the grass is too monochromatic and looks too "nice". It's also too tall. This is what I call "failing fast": experiment, look at the result, then use what was learned on a subsequent attempt. Committing to a large area would have taken longer and been a bigger failure.

![[Image: p734038408-2.jpg]](http://goodman312.zenfolio.com/img/s3/v25/p734038408-2.jpg)

Full sized photo click here (about 1mb):

Next I wanted to put on some bushes to fill the space on the right end where the "main" track curves gently back to the center. I was picturing a scene from the engine service area back in the 70's on the Hocking Valley Scenic Railway. There were always lots of bushes there - and cinder roadways.

I used Woodland Scenics ground foam for the bushes, then applied some Flock and Turf Scenic Texture from Scenic Express between the bushes. I also sprinkled a bit on the bushes themselves. I made a bit of a mess, but generally liked the look and the view down the cinder road. Not perfect, but a good lesson. Later I got the bright idea to put some static grass on top of the whole shebang - that was a bust; hairy bushes were the result.  Note: I have cleaned up the mess on the road since the photo was taken - I'll just pretend there was a severe windstorm the night before for these photos...

![[Image: p1001772110-2.jpg]](http://goodman312.zenfolio.com/img/s3/v26/p1001772110-2.jpg)

Full sized photo here

Overall scene angle:

![[Image: p678161247-2.jpg]](http://goodman312.zenfolio.com/img/s3/v23/p678161247-2.jpg)

Full sized photo here

Matt Goodman

Columbus, Ohio

Posts: 335

Threads: 27

Joined: Dec 2008

Hmm - seems I can't edit posts anymore, or I've gone blind.

The post above needs three edits - a correction, a clarification and an additional photo. Has this been changed?

Thanks

Matt Goodman

Columbus, Ohio

Posts: 335

Threads: 27

Joined: Dec 2008

Quick and easy texturing of painted ties:

After I painted the entire layout, I was slightly disappointed to see that the wood grain detail cast into the CVT strips had been covered. I think this was a combination of one two many coats of paint applied, and a "powder coat" look from the acryllic paint drying before hitting the ties.

In any case, I improved the look with a wire brush rubbed lengthwise along the ties.

Before treatment - flat, smooth look:

![[Image: p796762175-3.jpg]](http://goodman312.zenfolio.com/img/s10/v18/p796762175-3.jpg)

Wire brush:

![[Image: p672059905-2.jpg]](http://goodman312.zenfolio.com/img/s1/v22/p672059905-2.jpg)

After treatment - a bit of "pseudo grain". I wasn't worried about damage to the rail as I ended up brush painting most of the rail to differentiate it from the ties:

![[Image: p686262513-3.jpg]](http://goodman312.zenfolio.com/img/s3/v26/p686262513-3.jpg)

Full sized images here, here and here

Matt Goodman

Columbus, Ohio

Posts: 335

Threads: 27

Joined: Dec 2008

It seems I can't edit a post anymore - the one two posts before this needs some correction. Have I got blind??

Matt Goodman

Columbus, Ohio

|

Most impressed with your progress and results, so far...and continue to learn NEW stuff...thanks. Also (correct me, if necessary), FUTURE is very water resistant, when dry, but (IIRC) soluble by ammonia, (per the label instructions ?)...helpful for changes later. I never tried a "wetting agent" - alcohol, detergent, etc. - mixed with the Future, to combat the "floaties", as I used it only as a coating. Bob C.

Most impressed with your progress and results, so far...and continue to learn NEW stuff...thanks. Also (correct me, if necessary), FUTURE is very water resistant, when dry, but (IIRC) soluble by ammonia, (per the label instructions ?)...helpful for changes later. I never tried a "wetting agent" - alcohol, detergent, etc. - mixed with the Future, to combat the "floaties", as I used it only as a coating. Bob C.

Most impressed with your progress and results, so far...and continue to learn NEW stuff...thanks. Also (correct me, if necessary), FUTURE is very water resistant, when dry, but (IIRC) soluble by ammonia, (per the label instructions ?)...helpful for changes later. I never tried a "wetting agent" - alcohol, detergent, etc. - mixed with the Future, to combat the "floaties", as I used it only as a coating. Bob C.

Most impressed with your progress and results, so far...and continue to learn NEW stuff...thanks. Also (correct me, if necessary), FUTURE is very water resistant, when dry, but (IIRC) soluble by ammonia, (per the label instructions ?)...helpful for changes later. I never tried a "wetting agent" - alcohol, detergent, etc. - mixed with the Future, to combat the "floaties", as I used it only as a coating. Bob C.

Thanksgiving is safe.

Thanksgiving is safe.![[Image: p660217084-4.jpg]](http://goodman312.zenfolio.com/img/v20/p660217084-4.jpg)

![[Image: p810708485-4.jpg]](http://goodman312.zenfolio.com/img/v20/p810708485-4.jpg)

![[Image: p828676870-3.jpg]](http://goodman312.zenfolio.com/img/v16/p828676870-3.jpg)

![[Image: p734038408-2.jpg]](http://goodman312.zenfolio.com/img/s3/v25/p734038408-2.jpg)

Note: I have cleaned up the mess on the road since the photo was taken - I'll just pretend there was a severe windstorm the night before for these photos...

Note: I have cleaned up the mess on the road since the photo was taken - I'll just pretend there was a severe windstorm the night before for these photos...![[Image: p1001772110-2.jpg]](http://goodman312.zenfolio.com/img/s3/v26/p1001772110-2.jpg)

![[Image: p678161247-2.jpg]](http://goodman312.zenfolio.com/img/s3/v23/p678161247-2.jpg)

![[Image: p796762175-3.jpg]](http://goodman312.zenfolio.com/img/s10/v18/p796762175-3.jpg)

![[Image: p672059905-2.jpg]](http://goodman312.zenfolio.com/img/s1/v22/p672059905-2.jpg)

![[Image: p686262513-3.jpg]](http://goodman312.zenfolio.com/img/s3/v26/p686262513-3.jpg)