Posts: 180

Threads: 6

Joined: Feb 2013

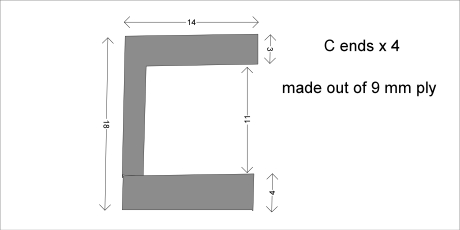

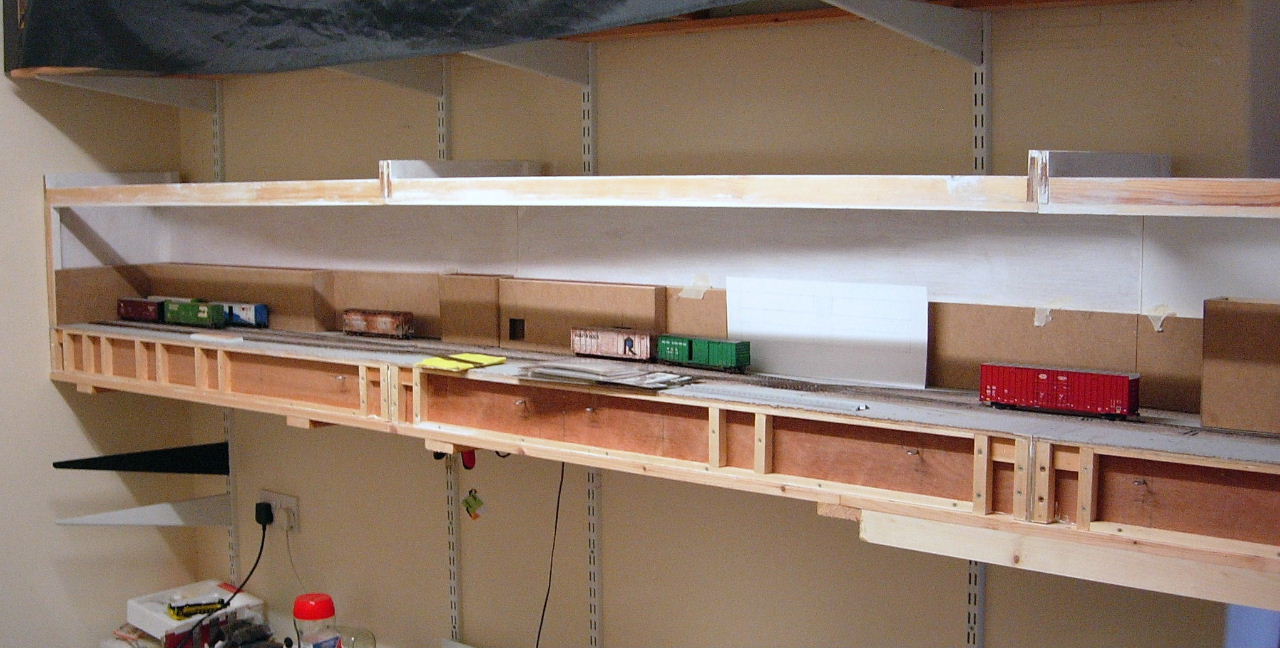

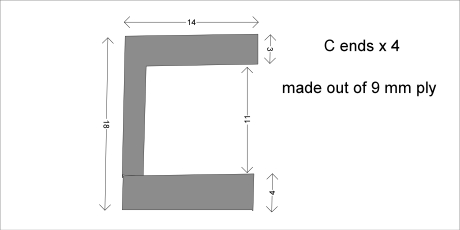

The layout is 12' x 14'' split into 3 x 48'' boards, construction is from 9mm ply for the main frames,6mm ply for the tops, the internal ends are built as a C shape, cut out of one piece of 9mm ply and support by 35 x 18 mm timber.

The front rail on all 3 boards is set back 18mm ,this is done so my point control is recessed (will be covered by 2mm MDF later), for ease of loading into my car, also there will be nothing for my operator to catch themselves on (got to think about H & S).

Ray

Posts: 180

Threads: 6

Joined: Feb 2013

Next job was to add the back boards which are 3mm ply supported by 35 x 18 mm timber.

the back board on board 3 has a hole cut out for access to the fiddle yard (in side the large building on the right of the plan)

next up was to give everything a coat of white primer.

Ray

Posts: 180

Threads: 6

Joined: Feb 2013

Posts: 99

Threads: 11

Joined: Jan 2010

That's looking very neat Ray

The more I look at the track plan the more it reminds me of an enlarged Haston

![[Image: 87e7ea25e7e7b90b52bf88a126cf9ee5.jpg]](http://images.tapatalk-cdn.com/15/12/18/87e7ea25e7e7b90b52bf88a126cf9ee5.jpg)

With a couple of extra points

Looking forward to seeing this

Will it be ready for TVNAM?

Nick needs more layouts for this year

Sent from my iPad using Tapatalk

Chris

England

Posts: 180

Threads: 6

Joined: Feb 2013

Are you saying I nicked you plan!!,now't like it and it's 6' longer

Not sure on TVNAM, still working on SWMBO, we fly on hols next day, would like to, always like to support him in some way.

Ray

Posts: 28

Threads: 6

Joined: May 2014

long island jack Wrote:[ATTACHMENT NOT FOUND]

Even the big boys do it, probably to save going to the nearest runround track!

Ray

BNSF here (western 'burbs of Chicago) runs locals (usually about 6-8 cars) with a GPxx-x on each end. Only one crew though AFAIK.

Posts: 180

Threads: 6

Joined: Feb 2013

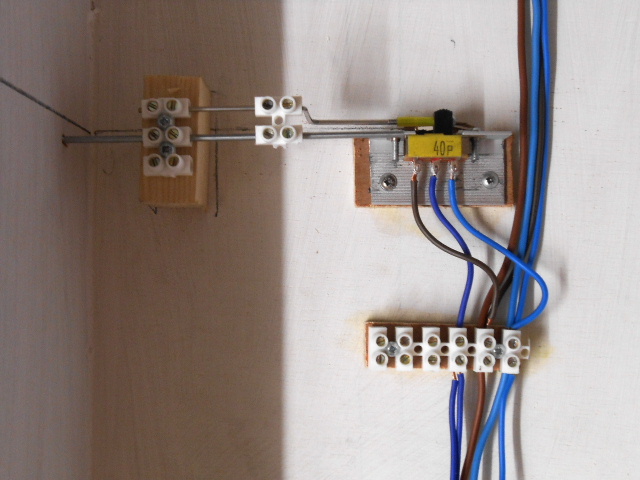

Once the track was secured, everything was wire up, point control is by a on-on slide switch, barbeque skewer and bike spokes .

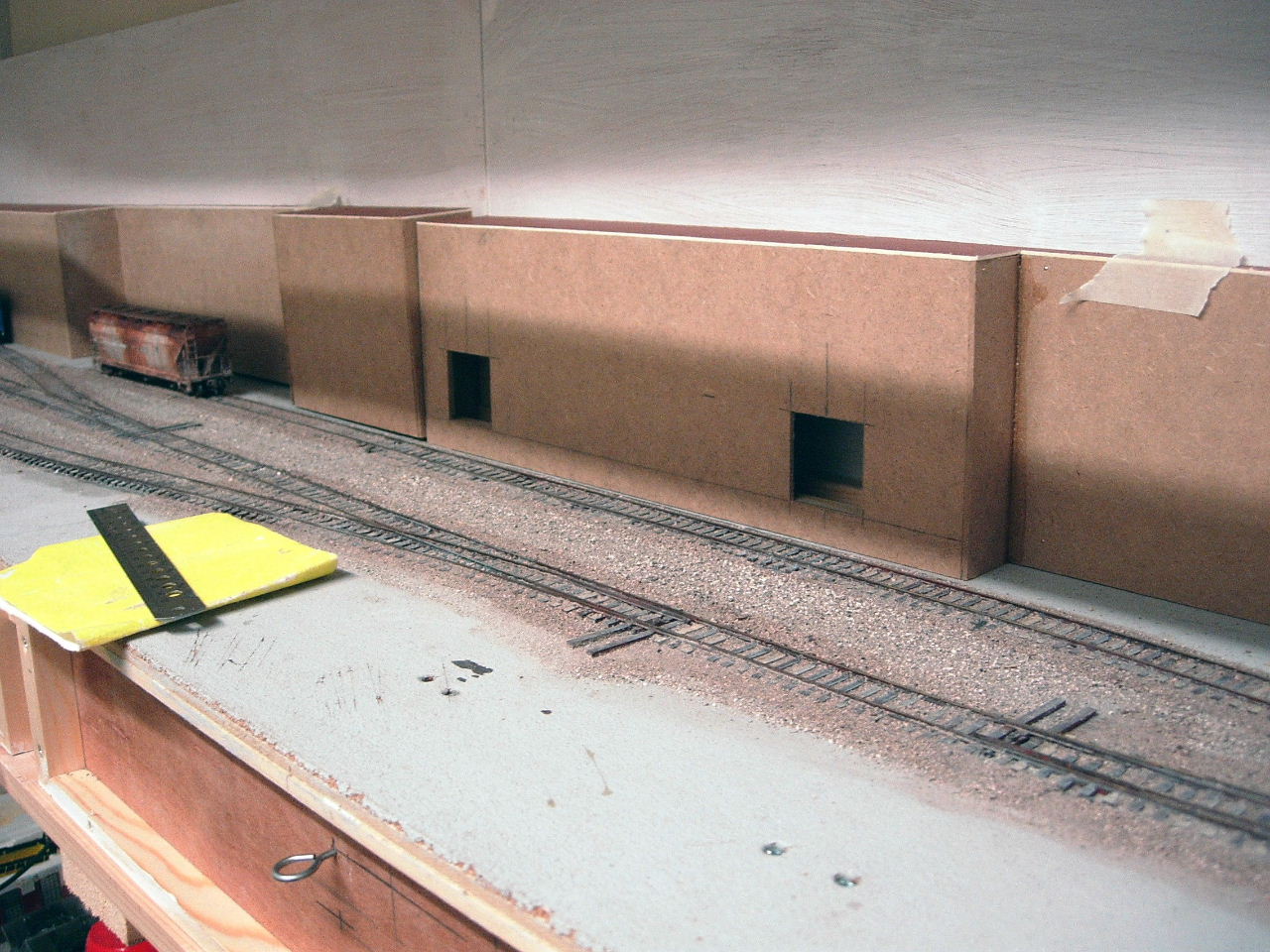

After thorough testing to make sure everything worked ok, it was on with the buildings, all made out of 2mm MDF and 10mm square timber, fixed on to 6 mm MDF bases

next job will be to clad these with plasticard

Ray

Posts: 899

Threads: 85

Joined: Jan 2012

long island jack Wrote:barbaque skewer and bike spokes . Very DIY  What are you using for ballast?

Posts: 180

Threads: 6

Joined: Feb 2013

Woodland Scenic fine ballast, which has been ground in a old coffee grinder

Ray

Posts: 180

Threads: 6

Joined: Feb 2013

Once I was happy with the formation of the building, i started to clad it with plastic, first was a 20 mm strip along the bottom made from 60 thou plasticard, this then had brick sheet butted on top, when this was all dry, vertical strips of 60 thou, were glued on to the rest of the building, then Wills metal siding is glued on top of the strips, then the trim is glued on the top edge and drip strip glued along the bottom edge.

it's bad to tell the detail with everything being white, but it's ok once painted

office block is made the same way.

Next job' paint and any concrete pads fitted.

Ray

Posts: 5,263

Threads: 195

Joined: Apr 2009

What is the reason to build the structures first from 2mm MDF and use the styrene as a cover only? Is that due to the extra strength and stability you need when traveling to exhibitions?

ps. I enjoyed that layout on RMWeb already and you are "guilty" of my last "shoebox" building and the end of my brick phase

Reinhard

Posts: 180

Threads: 6

Joined: Feb 2013

to add strength, as you say for exhibitions, some people may say its over engineered, again rule 1 applies.

glad the build gave you some inspiration for a change, though I don't think you need much persuading to change

Ray

Posts: 899

Threads: 85

Joined: Jan 2012

Looking good, can't wait to see it painted

Posts: 5,263

Threads: 195

Joined: Apr 2009

long island jack Wrote:..... some people may say its over engineered, ..... Not at all. Do you remember Gary from Houston? He used a solid wooden block to build his bank and he has a layout that will never move. I think it is not a bad thing if a solid kernel or wall like yours defines all right angles etc. and you can fully concentrate on the optical aspects. I think I would like to do it too if I had a stationary circular saw.

Reinhard

Posts: 180

Threads: 6

Joined: Feb 2013

I think I would like to do it too if I had a stationary circular saw.

I use a Sharpe knife and steel straight edge and patience

|

![[Image: 87e7ea25e7e7b90b52bf88a126cf9ee5.jpg]](http://images.tapatalk-cdn.com/15/12/18/87e7ea25e7e7b90b52bf88a126cf9ee5.jpg)

What are you using for ballast?

What are you using for ballast?