Posts: 380

Threads: 11

Joined: Sep 2010

Catt Wrote:Sounds like good customer service to me.  Are you going to attempt a repair?

Are you going to attempt a repair?

I might as well try... nothing to loose.

Posts: 28

Threads: 6

Joined: May 2014

Brakie Wrote:To bad one doesn't research his choice of industries before buying a single freight car.

True. I now have surplus bulkheads, 2-bay hoppers, corn syrup tankers, flour/grain hoppers and woodchip gons all because I changed LDEs in midstream. Oh well, maybe a non-proto transload can be worked in on the opposite side of the room.

Posts: 380

Threads: 11

Joined: Sep 2010

Posts: 612

Threads: 10

Joined: Feb 2011

Catt Wrote:Sounds like good customer service to me.  Are you going to attempt a repair?

Are you going to attempt a repair?

I'll second that comment.

Fixing the problem straight away, no hesitation, sending a new part via express. Excellent customer service. For the cost of a set of points and an express box she has retained a customer and prevented bad word of mouth or in this case bad word on the web, which can be far worse.

It would have been better if the problem had never occurred, but it has so, it needs fixing.

Good job Micro Engineering, now just investigate why it happened in the first place.

Mark

Fake It till you Make It, then Fake It some More

Posts: 2,418

Threads: 63

Joined: Dec 2008

Callum

You can always complicate your operating sessions by adding a bulkhead flat that doesn't go anywhere into the train. When your guest operators get complacent...

David

Moderato ma non troppo

Perth & Exeter Railway Company

Esquesing & Chinguacousy Radial Railway

In model railroading, there are between six and two hundred ways of performing a given task.

Most modellers can get two of them to work.

Posts: 380

Threads: 11

Joined: Sep 2010

I'm seriously thinking of using a new kind of support for the shelf of my shelf layout.

The last one was the standard section metal channel set on the wall (Brick) with the triangular steel arms that slot in. This time I want a seamless and very neat solution, a lot like Lance has been experimenting with. I found this which I think would worl well, the only change I would make is to leave out the bottom board (to allow access to wires) and then I would only use a 1/8th inch MDF or Masonite board on top, laminated to the 1 inch thick insulation board.

Posts: 612

Threads: 10

Joined: Feb 2011

Callum if you leave off the bottom board then the shelf will NOT be a Torsion Box design.

A torsion box design relies upon the two boards and the spacer timbers to achieve its strength, the most common torsion box you would be familiar with is a household hollow core door. A hollow core door is made up of the two outer panels, the edge timbers and a lock block where the door furniture is to be mounted, the rest of the inside of the door is filled with a cardboard webbing of the desired internal thickness which has been glued to the sides and the two outer skin boards. This is what creates the beam design to give the torsion box its strength in multiple directions.

You could build the above design, but modify it to include wiring holes through the spacing battens and also cut windows in the bottom board to facilitate running and mounting your wiring and other sub grade requirements.

I have made several torsion boxes at work, one being a work bench and the others being for a model train layout. The train layout was very flexible until I installed the bottom panel with its cut outs and then it began to stiffen up.

Hope this helps.

Mark

Fake It till you Make It, then Fake It some More

Posts: 380

Threads: 11

Joined: Sep 2010

Hi Mark,

Fully agree with you and after posting I've been thinking a lot and the idea of the Windows I the bottom are ideal. I was thinking of fairly small ones cut inbetween the cross members(with holes) and they only need to be 5 inches wide and line up with my central bus cable. I remember from my last layout my wiring was very neat and simple. My idea was to maybe not glue the bottom panel in but rather to fasten it with screws so I can always undo it in case I have a big sue but that may weaken it too much.

I want to try and keep the whole shelf thinner than 3inches, will have a 4 inch facia on it. The top hood will have a 5 or 6inch facia and might need to be as think as the lower one as the lights can be heavy, although I think I'm going to try god undercounter light this time.

Any suggestions o the type of timber to use for the clear and inner members?

Posts: 380

Threads: 11

Joined: Sep 2010

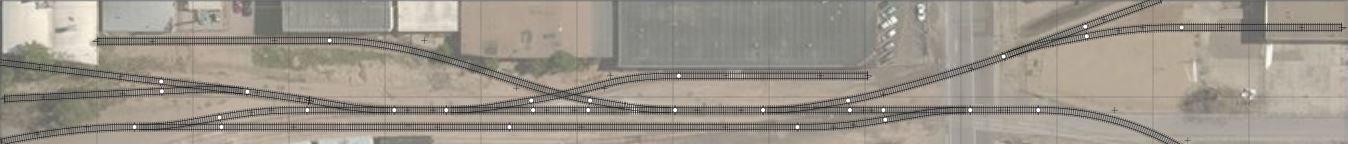

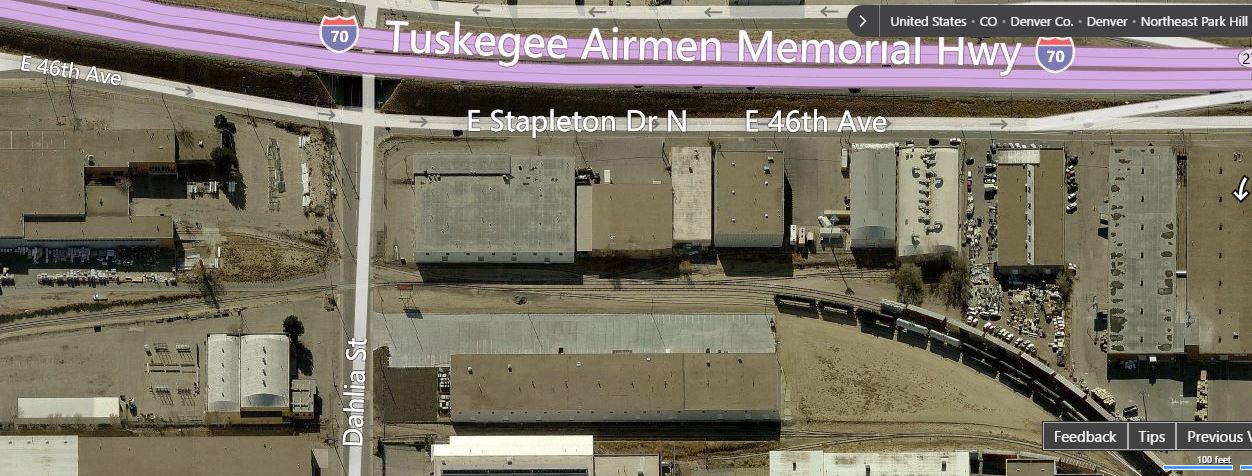

Been looking around on Bing and Google maps. Long time ago I found a Industrial Zone in Denver CO and they have some cool older areas with model size track arrangements.

Here is the birds eye from Bing:

I've taken an aerial snap of the southern side of the whole area (which could make a wonderful full room layout if you have the space) flipped it to suit my room and overlaid some track almost to scale. This has some compression in it but still retains the feel IMHO.

This is a bit longer than my room, over 14ft is needed to do it 1:1 as well as the shelf would need to be 24 inches deep but I can't go that deep...here it is on a 18 inch shelf with a little depth compression to save some space. Ideally I only want a 16 inch shelf but may be able to push.

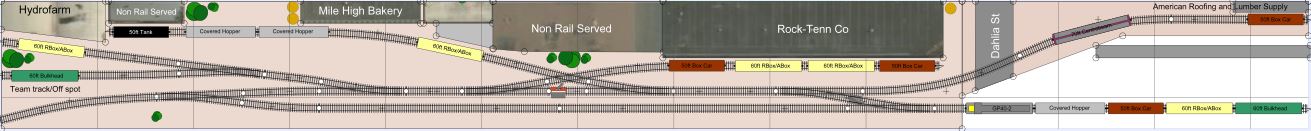

Its a cool idea for someone of they have 14-15ft and space for a 20inch odd shelf. I like the area and the buildings are old and not all just grey boxes. I'm going to work on it some more to see if I can arrange it to fit my space a little better without losing spots. If you look carefully on Google and Bing you will see all the buildings in the longer spur are/were rail served....points of you can spot the loading platform..

So far I have something like this on a 16 inch wide shelf but it needs work...and yes I know the track runs close to the front edge, could always put up a fence or clear perspex safety barrier 1 inch high. Even thought of lazer etching a chain link fence pattern into it for effect but haven't given that enough thought.

Posts: 180

Threads: 6

Joined: Feb 2013

Callum

You could always make a add on bit to fit the front, which would clamp on when your switching the layout, un clamped when not and store it on top of your lighting rig.

Ray

Posts: 380

Threads: 11

Joined: Sep 2010

long island jack Wrote:Callum

You could always make a add on bit to fit the front, which would clamp on when your switching the layout, un clamped when not and store it on top of your lighting rig.

Ray

Good idea Ray

Posts: 380

Threads: 11

Joined: Sep 2010

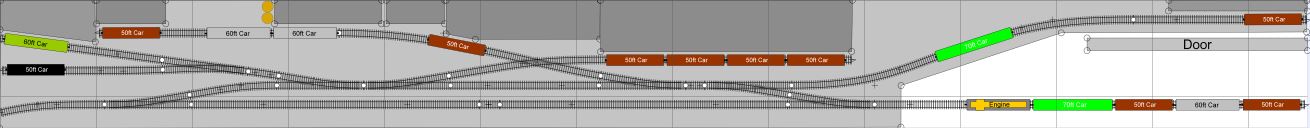

This is probable how I would arrange things for car spots, some of the rear buildings would have ceased rails service. I really enjoy this and its a lot more interesting than the Alpha Packaging branch/ISL. I think I've learnt now that I really would only want to build something based on a real area and try and model it exactly.

Posts: 11

Threads: 0

Joined: Dec 2015

You did that in Any rail, right? How do you show the car spots?

Sent from my Wileyfox Swift using Tapatalk

Posts: 380

Threads: 11

Joined: Sep 2010

Not sure what you mean, Anyrail doesn't do it for you if that's what you mean. I had to make objects (rolling stock) in Anyrail and then used those to indicate where I would place cars.

Posts: 11

Threads: 0

Joined: Dec 2015

That's what I meant, cheers

Sent from my Wileyfox Swift using Tapatalk

Are you going to attempt a repair?