Posts: 1,682

Threads: 101

Joined: Dec 2011

Today's progress include a new cab roof and a few cab details. There's still some fine work and details to add, but this is going in the right direction and definitely looks like an early 20th locomotive.

![[Image: IMG_1378b_zpsxoznghja.jpg]](http://i603.photobucket.com/albums/tt111/sailormatlac/Hedley%20Junction/IMG_1378b_zpsxoznghja.jpg)

I also completed the boiler straps. However, I found out the lower running board means I'll have to add boiler bands under the locomotive weight/lowe boiler. I'm not sure if it will look good once painted as Russian iron. No, adding low running board on a Bachmann 2-8-0 is not an easy task. They are attached to the plastic shell AND metal weight. Not a good thing when you want to keep the shell removable. I'll have to come up with a practical solution about that. Also, the steam pipes out of the cylinders will have to go away.

I also started to cut running boards to length and carved the turret with a large drill bit. Safety valves will be added later.

The next step is to complete the boiler once for all, pre-drill all the appliance holes and make removable pipings. It won't be easy, but at least piping is minimal. I gave a few thoughts about the pilot and the scratchbuilding way is the best in term of time, price and results. Some parts including a new air pump, headligh and spoked pilot wheels are ordered. Unfortunately, I have now idea when I'll get them. At least, they won't prevent me from completing the model and they can easily be added later on.

Matt

Posts: 1,682

Threads: 101

Joined: Dec 2011

The GTR 719 is progressing little by little. Recent work includes modifying the cylinders, sculpting and detailing the turret and adding cab roof hatches.

![[Image: IMG_1387b.jpg]](https://3.bp.blogspot.com/-NzuG8ut-_5U/V5YtWxanO9I/AAAAAAAAC5k/WJyZfwX843g_jrPhkJwkGg4O6LluWS1bACEw/s1600/IMG_1387b.jpg)

GTR 719 was built as a compound locomotive. I was required to remove the steam pipes out of the cylinder and replace them by square boxes made out of laminated styrene filed to size. Small steps with rounded corners were added on top of the boxes just like the prototype. Before gluing the boxes, I filed the cylinder tops flat. This way, I didn't have to adapt the boxe profile to the cylinder radius, which could have been tricky and not easy to glue. Archer anti-skid thread pattern decals will be added later on top of the steps and lubricator pipes too.

![[Image: IMG_1381b.jpg]](https://1.bp.blogspot.com/-TIv2IORSkio/V5YtmI1Ia4I/AAAAAAAAC5g/5rEBebniz9keITV2EZg43gLAXe4vRAnjwCEw/s1600/IMG_1381b.jpg)

The steam turret is made of a Roundhouse sand dome from a 0-6-0T shell. I extended it with Magic Sculpt putty filed to size then glued with putty onto the boiler. When everything was dried, I drilled a small pilot hole on top and carefully using a larger drill bit by hand, I hollowed the interior.

![[Image: IMG_1379b.jpg]](https://2.bp.blogspot.com/-MTSwtcgMbH8/V5YtVjzb9bI/AAAAAAAAC5I/XMDQqWO4hg0AZv8TcWN1BK54Rt-hhwwHACLcB/s1600/IMG_1379b.jpg)

A flat floor for the turret inside was made out of 0.5 mm styrene. Safety valves taken from a Bachmann 4-4-0 shell and one salvaged from the 2-8-0 shell where glued following the prototype.

![[Image: IMG_1383b.jpg]](https://4.bp.blogspot.com/-ggrLQKgzOiA/V5YtWL0OJuI/AAAAAAAAC5M/6bmMcIUxvdACdzsy_7_tbB0MAFlMONidACEw/s1600/IMG_1383b.jpg)

The new cab roof got a putty job to smooth rough parts. New roof hatches are being build from styrene sheet. The hatches aren't yet glued, what you see are the side extensions that will be later filed down a little bit to the correct height.

![[Image: IMG_1385b.jpg]](https://4.bp.blogspot.com/-GAnW9FNhKXA/V5YtWl0GA8I/AAAAAAAAC5Y/xRYrcHzkZhgQ-qZhXBec20QPQ4Z1BT-FgCEw/s1600/IMG_1385b.jpg)

Completing the running boards and drilling mounting holes in the boiler are among my next challenges. A tedious sand job to smooth out the surfaces before painting will be also required.

![[Image: IMG_1388b.jpg]](https://1.bp.blogspot.com/-yuEBDpRPoWM/V5YtYuBaMCI/AAAAAAAAC5k/UH7okxJ8a5YXghEQqydicc8DXs-2hYVkwCEw/s1600/IMG_1388b.jpg)

I'm really pleased to see the Bachmann stock model morphing into something completely different.

Matt

Posts: 2,959

Threads: 158

Joined: Dec 2008

Nice work so far!

--

Kevin

Check out my Shapeways creations!

3-d printed items in HO/HOn3 and more!

<!-- m --><a class="postlink" href="https://www.shapeways.com/shops/kevin-s-model-train-detail-parts">https://www.shapeways.com/shops/kevin-s ... tail-parts</a><!-- m -->

Posts: 1,682

Threads: 101

Joined: Dec 2011

The biggest problem you will encounter while kitbashing a Bachmann 2-8-0 is related to the running board height. If they are mounted lowe, i.e. flush with the cab bottom, there will be lower than the boiler shell.

![[Image: IMG_1412b.jpg]](https://1.bp.blogspot.com/--LSqk6kq1EE/V5iW_OC6ujI/AAAAAAAAC6s/KUk4gKz6CD0c58HwJCUsva21iSQFn1EGQCLcB/s1600/IMG_1412b.jpg)

This is a double issue. First, the Bachmann boiler is made a a plastic shell and a pair metal weights. You'll will see the seam between both part and slots for mounting screws. Also, the weights are undetailed (no boiler straps, etc.).

![[Image: IMG_1417b.jpg]](https://4.bp.blogspot.com/-y4SlidaaDr0/V5iW-RZedHI/AAAAAAAAC6o/CDvbLQenNGsmCC7dwNpAcIYBjs5qLv1bQCLcB/s1600/IMG_1417b.jpg)

The second problem is related to mounting the running boards. You need them to be sturdy enough to survive normal handling conditions and to be locatedd in a such fashion they won't be nuisance when dismantling the locomotive for maintenance. This means you have to mount the running boards on an incomplete shell and this is the big challenge.

![[Image: IMG_1418b.jpg]](https://2.bp.blogspot.com/-k_035lCAGHw/V5iW_Sod5MI/AAAAAAAAC6w/EOgShn-55bcqpKQqbCcF6Ji_UGGyXioiwCLcB/s1600/IMG_1418b.jpg)

After discussing the problem with Doctorwayne, we came up sith a set of different solutions. I decided to use one of them and will explain how it works. I suspect this is a solution similar to the one Marty McGuirk and Iain Rice came up in a 1999 MR article which unfortunately I couldn't locate at the local model railway association library.

![[Image: IMG_1419b.jpg]](https://2.bp.blogspot.com/-a_I4TLAVqTQ/V5iXAnJH3pI/AAAAAAAAC60/36u_SA4FmJEZdLpqw8eUpxuoRl0eBHXIwCLcB/s1600/IMG_1419b.jpg)

The basic idea is to simply extend the plastic shell as low as the running boards will be mounted. It means adding extra styrene sheet at the bottom of the shell. However, this simplistic solution require you to mill the metal weights to remove a equivalent amount of metal. In my case, 2 mm thick of styrene must be added to the boiler. This is exactly the thicknees of the metal weights walls encasing the motor.

![[Image: IMG_1430b.jpg]](https://4.bp.blogspot.com/-yKxs9NSTsso/V5iX4X6dOaI/AAAAAAAAC7I/auU0DSJp08gnjxSISPnTIZEt3CvRRfnXQCLcB/s1600/IMG_1430b.jpg)

Milling the frame took about 90 minutes using unspecialized tools like a tool grinder, a Dremel sanding drum and a large flat file to finish the work.

![[Image: IMG_1425b.jpg]](https://4.bp.blogspot.com/-GTmjfocTMN4/V5iXCHVaahI/AAAAAAAAC68/7lJ0CMmEIJoOeJTZfvIVtLsSPcBhiIdgQCLcB/s1600/IMG_1425b.jpg)

When done, styrene sheets were laminated against the boiler and left to dry overnight. At this point, the metal weights slide easily inside the shell as it should be. It must be noted you must mill the weights on all their height to make sure it will be possible to insert it. You also need to mill it up to the fron too.

![[Image: IMG_1429b.jpg]](https://2.bp.blogspot.com/-DdVospHfIDM/V5iXBdM_GjI/AAAAAAAAC64/nQWN_vCdidwDzPeOofwgQa5WdlQbe2QiwCLcB/s1600/IMG_1429b.jpg)

To attach the running boards, small brackets will be pinned and cemented into the new shell extentions. Brass wire, music wire or phosphore bronze wire can be used: choose a material that will be strong enough to keep its shape under normal handling conditions. The new running boards will be them glued on the brackets, exactly just like the real prototypes. If wanted, the running board could be made out of brass and soldered on the bracket to make a single and sturdy assembly.

![[Image: IMG_1432b.jpg]](https://1.bp.blogspot.com/-xDAXVxsxdaY/V5iXC3UCGyI/AAAAAAAAC7A/_4WMW--jCjcgehwR7au2sCKMTjCqVwUUwCLcB/s1600/IMG_1432b.jpg)

Matt

Posts: 5,859

Threads: 175

Joined: Dec 2008

That's looking good, Matt, as is your work on the low pressure cylinder.

Wayne

Posts: 1,682

Threads: 101

Joined: Dec 2011

doctorwayne Wrote:That's looking good, Matt, as is your work on the low pressure cylinder.

Wayne

More on the LP cylinder later.

BTW, could it be possible to change the thread name to "HO Grand Trunk 2-8-0 (Class D2)"?

Best regards,

Matt

Posts: 1,682

Threads: 101

Joined: Dec 2011

Question: for a 1907 locomotive, would the boiler straps be in brass or Russian iron?

Here is an update with the extended boiler and new straps made of tape. The other styrene straps were sanded down to make them thinner and more prototypical.

![[Image: IMG_1436b_zps9vysxfiu.jpg]](http://i603.photobucket.com/albums/tt111/sailormatlac/Hedley%20Junction/IMG_1436b_zps9vysxfiu.jpg)

Matt

Posts: 5,859

Threads: 175

Joined: Dec 2008

sailormatlac Wrote:....BTW, could it be possible to change the thread name to "HO Grand Trunk 2-8-0 (Class D2)"?

Done!

sailormatlac Wrote:Question: for a 1907 locomotive, would the boiler straps be in brass or Russian iron?....

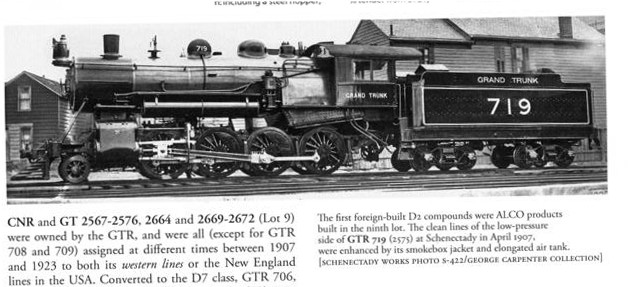

A picture of GT 719 (either posted in this thread, or one of the ones which I sent to you), shows a boiler that doesn't appear to be painted, but rather a version of Russian iron, and the boiler bands appear to be lighter in colour - possibly brass. On that locomotive, the smokebox is lagged (sheathed) and appears to be painted, as seen below. The photo is dated 1907.

Wayne

Posts: 1,682

Threads: 101

Joined: Dec 2011

Thank you Wayne!

I did some work on the locomotive today by spraying the model with black primer to see if there was any obvious defects on the shell. So far, it is better than I thought and touch up will be minimal.

My next challenge was installing inspection and clean out plugs. I had two choices: buy expensive brass parts that don't look like the prototype and are oversized or make them myself. I went with the Red Green's second option as you can guess.

I made the plugs with a combination of holes and 0.040" styrene rod. I first drilled a small pilot hole in the shell of same diameter as the rod.

![[Image: IMG_1438b.jpg]](https://2.bp.blogspot.com/-ty4yKL0rja4/V5pVBYXOxUI/AAAAAAAAC7o/a6nAbzKoKRQyr-enFtfFHCPbD9jWcanCwCEw/s1600/IMG_1438b.jpg)

Then, using a 5/64" drill bit, I enlarged the hole surperficially to create a small recess in the boiler jacket.

![[Image: IMG_1439b.jpg]](https://1.bp.blogspot.com/-00sCfdWKx0o/V5pVBxKHbaI/AAAAAAAAC7o/Wfp3zbdb0LUi-A5dLHGIYya9Vb9PGzBRACEw/s1600/IMG_1439b.jpg)

Finally, a piece of styrene rod was glued into the small hole. The rod was extending from the surface and was later cut flush with the boiler using a X-Acto blade.

![[Image: IMG_1440b.jpg]](https://4.bp.blogspot.com/-R6_udYvoHcA/V5pVBrKgMCI/AAAAAAAAC7o/f8hDGSvojB4LH555dZZZYJCxsgbpuT4HQCEw/s1600/IMG_1440b.jpg)

Sure, it lacks the typical rim around the plug, but on many older pictures, it is almost undiscernable. If one would want to make more detailed plugs, I would advise to make the parts independantly, then drill the boiler and insert the plugs. The plugs could be made out of a sprue or a styrene rod with a diameter slightly larger than the largest drilling bit used to shape the plug. Follow my original instruction and you will soon have cheap and easy to install inspection plugs.

![[Image: IMG_1444b.jpg]](https://1.bp.blogspot.com/-xGv3Fog7wjY/V5pW6mlsHqI/AAAAAAAAC7w/VPUfsloq6hU7eGxyzvzIrElWeNNBMVXnwCLcB/s1600/IMG_1444b.jpg)

To be noted, I also drilled the stanchions mounting holes according to the prototype and enlarged the cab windows. There are still a few holes to drill and running boards to mount.

Matt

Posts: 229

Threads: 6

Joined: Aug 2014

Hi,

Fantastic Work. Looking Great.

Regards,Chris

Posts: 1,682

Threads: 101

Joined: Dec 2011

Twist Wrote:Hi,

Fantastic Work. Looking Great.

Regards,Chris

Thanks Chris. If Canada Post don't go on strike too quickly, I should get parts to complete the locomotive.

Matt

Posts: 891

Threads: 56

Joined: Mar 2015

This is some impressive work, Matt. I like how you made the steam turret.

I'm also hoping that the Canada Post strike doesn't happen, I'll be needing to order some things soon as well.

|

![[Image: IMG_1378b_zpsxoznghja.jpg]](http://i603.photobucket.com/albums/tt111/sailormatlac/Hedley%20Junction/IMG_1378b_zpsxoznghja.jpg)

![[Image: IMG_1378b_zpsxoznghja.jpg]](http://i603.photobucket.com/albums/tt111/sailormatlac/Hedley%20Junction/IMG_1378b_zpsxoznghja.jpg)

![[Image: IMG_1387b.jpg]](https://3.bp.blogspot.com/-NzuG8ut-_5U/V5YtWxanO9I/AAAAAAAAC5k/WJyZfwX843g_jrPhkJwkGg4O6LluWS1bACEw/s1600/IMG_1387b.jpg)

![[Image: IMG_1381b.jpg]](https://1.bp.blogspot.com/-TIv2IORSkio/V5YtmI1Ia4I/AAAAAAAAC5g/5rEBebniz9keITV2EZg43gLAXe4vRAnjwCEw/s1600/IMG_1381b.jpg)

![[Image: IMG_1379b.jpg]](https://2.bp.blogspot.com/-MTSwtcgMbH8/V5YtVjzb9bI/AAAAAAAAC5I/XMDQqWO4hg0AZv8TcWN1BK54Rt-hhwwHACLcB/s1600/IMG_1379b.jpg)

![[Image: IMG_1383b.jpg]](https://4.bp.blogspot.com/-ggrLQKgzOiA/V5YtWL0OJuI/AAAAAAAAC5M/6bmMcIUxvdACdzsy_7_tbB0MAFlMONidACEw/s1600/IMG_1383b.jpg)

![[Image: IMG_1385b.jpg]](https://4.bp.blogspot.com/-GAnW9FNhKXA/V5YtWl0GA8I/AAAAAAAAC5Y/xRYrcHzkZhgQ-qZhXBec20QPQ4Z1BT-FgCEw/s1600/IMG_1385b.jpg)

![[Image: IMG_1388b.jpg]](https://1.bp.blogspot.com/-yuEBDpRPoWM/V5YtYuBaMCI/AAAAAAAAC5k/UH7okxJ8a5YXghEQqydicc8DXs-2hYVkwCEw/s1600/IMG_1388b.jpg)

![[Image: IMG_1412b.jpg]](https://1.bp.blogspot.com/--LSqk6kq1EE/V5iW_OC6ujI/AAAAAAAAC6s/KUk4gKz6CD0c58HwJCUsva21iSQFn1EGQCLcB/s1600/IMG_1412b.jpg)

![[Image: IMG_1417b.jpg]](https://4.bp.blogspot.com/-y4SlidaaDr0/V5iW-RZedHI/AAAAAAAAC6o/CDvbLQenNGsmCC7dwNpAcIYBjs5qLv1bQCLcB/s1600/IMG_1417b.jpg)

![[Image: IMG_1418b.jpg]](https://2.bp.blogspot.com/-k_035lCAGHw/V5iW_Sod5MI/AAAAAAAAC6w/EOgShn-55bcqpKQqbCcF6Ji_UGGyXioiwCLcB/s1600/IMG_1418b.jpg)

![[Image: IMG_1419b.jpg]](https://2.bp.blogspot.com/-a_I4TLAVqTQ/V5iXAnJH3pI/AAAAAAAAC60/36u_SA4FmJEZdLpqw8eUpxuoRl0eBHXIwCLcB/s1600/IMG_1419b.jpg)

![[Image: IMG_1430b.jpg]](https://4.bp.blogspot.com/-yKxs9NSTsso/V5iX4X6dOaI/AAAAAAAAC7I/auU0DSJp08gnjxSISPnTIZEt3CvRRfnXQCLcB/s1600/IMG_1430b.jpg)

![[Image: IMG_1425b.jpg]](https://4.bp.blogspot.com/-GTmjfocTMN4/V5iXCHVaahI/AAAAAAAAC68/7lJ0CMmEIJoOeJTZfvIVtLsSPcBhiIdgQCLcB/s1600/IMG_1425b.jpg)

![[Image: IMG_1429b.jpg]](https://2.bp.blogspot.com/-DdVospHfIDM/V5iXBdM_GjI/AAAAAAAAC64/nQWN_vCdidwDzPeOofwgQa5WdlQbe2QiwCLcB/s1600/IMG_1429b.jpg)

![[Image: IMG_1432b.jpg]](https://1.bp.blogspot.com/-xDAXVxsxdaY/V5iXC3UCGyI/AAAAAAAAC7A/_4WMW--jCjcgehwR7au2sCKMTjCqVwUUwCLcB/s1600/IMG_1432b.jpg)

![[Image: IMG_1436b_zps9vysxfiu.jpg]](http://i603.photobucket.com/albums/tt111/sailormatlac/Hedley%20Junction/IMG_1436b_zps9vysxfiu.jpg)

![[Image: IMG_1438b.jpg]](https://2.bp.blogspot.com/-ty4yKL0rja4/V5pVBYXOxUI/AAAAAAAAC7o/a6nAbzKoKRQyr-enFtfFHCPbD9jWcanCwCEw/s1600/IMG_1438b.jpg)

![[Image: IMG_1439b.jpg]](https://1.bp.blogspot.com/-00sCfdWKx0o/V5pVBxKHbaI/AAAAAAAAC7o/Wfp3zbdb0LUi-A5dLHGIYya9Vb9PGzBRACEw/s1600/IMG_1439b.jpg)

![[Image: IMG_1440b.jpg]](https://4.bp.blogspot.com/-R6_udYvoHcA/V5pVBrKgMCI/AAAAAAAAC7o/f8hDGSvojB4LH555dZZZYJCxsgbpuT4HQCEw/s1600/IMG_1440b.jpg)

![[Image: IMG_1444b.jpg]](https://1.bp.blogspot.com/-xGv3Fog7wjY/V5pW6mlsHqI/AAAAAAAAC7w/VPUfsloq6hU7eGxyzvzIrElWeNNBMVXnwCLcB/s1600/IMG_1444b.jpg)