02-06-2010, 11:59 AM

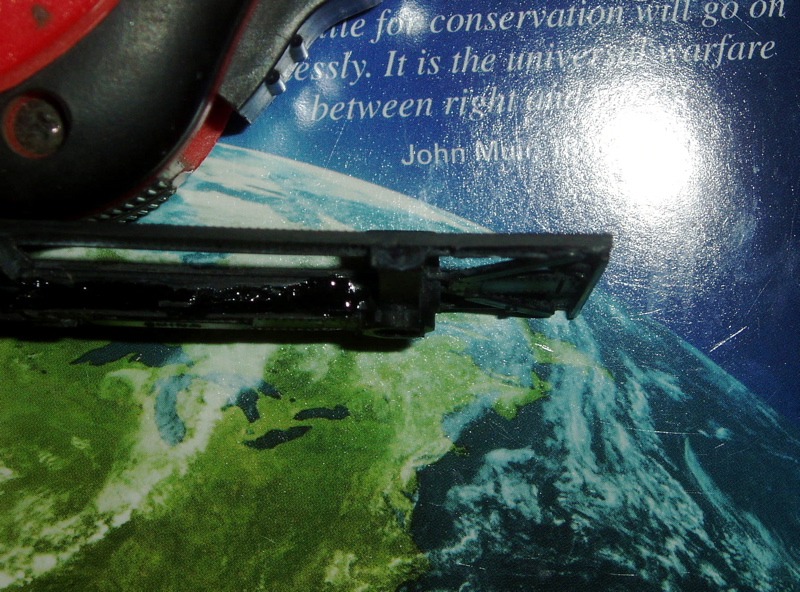

If you notice in the prototype photo above, the frame is thicker between the bolster and the end of the car. The frame also appears to have a flange on the top and bottom that protrudes slightly out from the inner "webbing". If you look at the photograph of my model frame, the frame is the same thickness towards the end. I assume the model designer kept the edges thinner to allow for the swing of the truck-mounted coupler.

I will need to build up the ends of the frame in order to be more prototypically accurate, and in order to have the frame thick enough to support body mounted couplers. The frame is very thin and flimsy. I actually had to glue the two pieces back together in order for it to be stiff enough to file and sand on. I will build up the ends of the frame by either laminating two pieces of styrene to represent the web and the bottom flange, or by gluing one thicker piece of styrene to the end, and filing out the center "web".

I will need to build up the ends of the frame in order to be more prototypically accurate, and in order to have the frame thick enough to support body mounted couplers. The frame is very thin and flimsy. I actually had to glue the two pieces back together in order for it to be stiff enough to file and sand on. I will build up the ends of the frame by either laminating two pieces of styrene to represent the web and the bottom flange, or by gluing one thicker piece of styrene to the end, and filing out the center "web".

--

Kevin

Check out my Shapeways creations!

3-d printed items in HO/HOn3 and more!

<!-- m --><a class="postlink" href="https://www.shapeways.com/shops/kevin-s-model-train-detail-parts">https://www.shapeways.com/shops/kevin-s ... tail-parts</a><!-- m -->

Kevin

Check out my Shapeways creations!

3-d printed items in HO/HOn3 and more!

<!-- m --><a class="postlink" href="https://www.shapeways.com/shops/kevin-s-model-train-detail-parts">https://www.shapeways.com/shops/kevin-s ... tail-parts</a><!-- m -->