12-18-2010, 10:48 AM

I can't really work on the bridge until after new years " when I can take over the dinning room table again ". So until then I will keep my self occupied with a few other things that need attention. I will soon need to build a LOT of #4 switches, in order to mass produce them a little easier I built a jig for cutting and spacing the ties. I used the fast tracks jigs to make the armatures for the switches so my jigs are built around there dimensions.

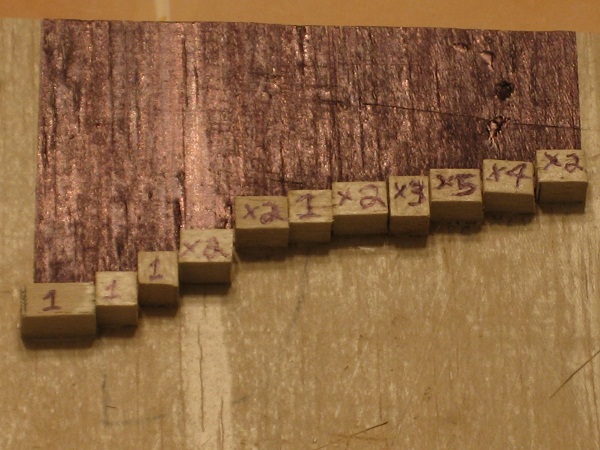

It's pretty simple. just some strip wood glued to a scrap of plywood. I painted it so that it would show up better for the photos.

It's pretty simple. just some strip wood glued to a scrap of plywood. I painted it so that it would show up better for the photos.

The top section is for sizing and marking the length of each tie, each step is also marked with a number that indicates how many to cut at each length. If I ever make another I will make sure that each step will hold the proper amount of ties for each length. It was something that I didn't think of until I used it for the first time.

If I ever make another I will make sure that each step will hold the proper amount of ties for each length. It was something that I didn't think of until I used it for the first time.

The top section is for sizing and marking the length of each tie, each step is also marked with a number that indicates how many to cut at each length.

My other car is a locomotive, ARHS restoration crew