04-07-2011, 03:04 PM

Dear All,

Following my recent disappointment with some scratchbuilt track and its Peco Code 75 replacement, and after subsequent consulatations with a couple of experienced UK forum members (thank you Dave Long and Jez), I have decided to opt for either Shinohara Code 70 or Peco Code 83.

Peco Code 83 is known to be more sympathetic to HO gauge wheelsets than its sibling 75, however, Code 70 is more appropriate for that industrial look I'm trying to create than the typically 'mainline' 83. Consideration has also been given to Proto 87 'Superfine' turnouts and Fast Tracks products, however, as my confidence has been somewhat knocked, I prefer to opt for the RTR stuff, if this layout is ever to progress!

Another factor has been cost, which has pretty much ruled out Fast Tracks for now, and lest I waste further money on unsuitable products, I've decided to 'back off a little' in attempt to stop my enthusiasm running away with me. One very good reason for this drawing of breath is that I await an update from Dave who has kindly offered to let me know the outcome of some provisionl tests with the Shinohara products..........when they eventually arrive.....although he's confident its imminent

Anyway, "what's the point of this post?" I may well here you ask, bearing in mind those of you who have dared....sorry.....'cared' to follow any of this half-baked nonsense to date.

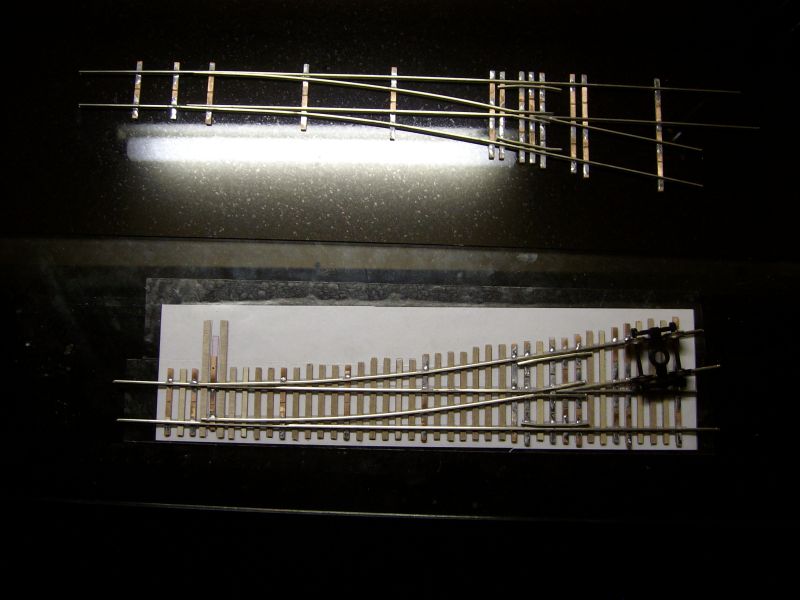

Well, I couldn't quite kill my blind enthusiasm whilst sitting twiddling my thumbs, so, armed with some offcuts of Peco Code 75 rail, sheets of tables and dimensions downloaded from the NMRA site, a vernier gauge, a couple of track templates courtesy of Fast Tracks' site and the old adage 'nothing ventured.....' echoing about the grey matter, I set about producing this:

(apologies for the poor quality of this one)

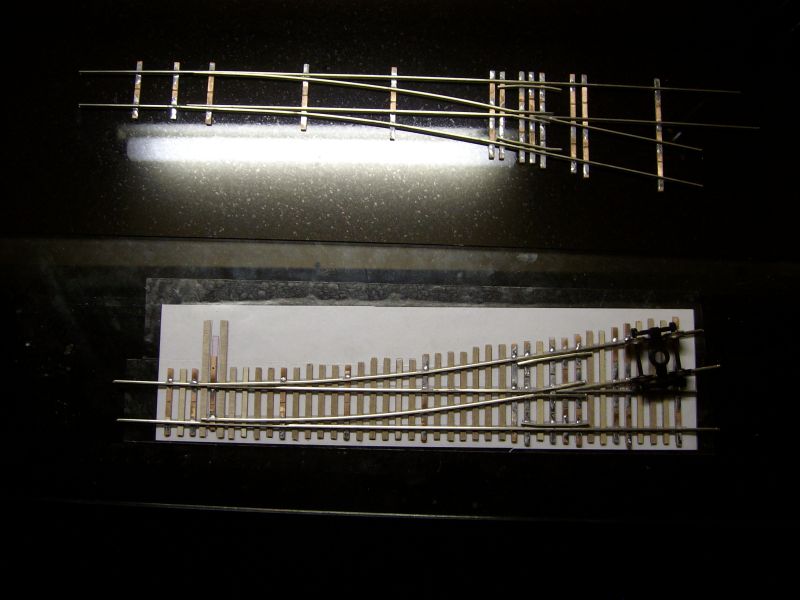

You can see the first I built at the top of the photo; okay, but not as good as the second, which is the one with full 'ties'.

The process was much improved and made a whole lot easier, after I thought about using a gauge to steady the rail against while soldering. A couple of off cuts of aluminium from a door plate (0.047" thick, one thousandth of an inch less than the standard I'd been using - although NMRA states a target of 0.044" for flangeway) purchased for the purpose of producing those excellent 'Heath Robinson' manual turnout controls fabricated by Kurt, came in useful here.

Probably the most laborious part of the construction has been the fabrication of the ties. I couldn't source any wood of suitable proportions locally so ended up laminating a couple of thin sheets of veneer type material that I had lying around in order to match the height of the PCB strips. I almost ended up losing the will to live!

It's not finished yet and I've still to wire it electrically for further testing, however, early signs are good: the truck you see flies through undaunted and although my sole loco has yet to traverse under its own steam, there doesn't appear to be any resistance due to loss of gauge and, reassuringly, no apparent 'wheel drop'.

I shall conduct some tests tomorrow and get back to you - although, if I don't, you'll know that this has also gone pear shaped and I've taken up the far simpler past time of placing ships in bottles

Regards for now,

Jonte

Following my recent disappointment with some scratchbuilt track and its Peco Code 75 replacement, and after subsequent consulatations with a couple of experienced UK forum members (thank you Dave Long and Jez), I have decided to opt for either Shinohara Code 70 or Peco Code 83.

Peco Code 83 is known to be more sympathetic to HO gauge wheelsets than its sibling 75, however, Code 70 is more appropriate for that industrial look I'm trying to create than the typically 'mainline' 83. Consideration has also been given to Proto 87 'Superfine' turnouts and Fast Tracks products, however, as my confidence has been somewhat knocked, I prefer to opt for the RTR stuff, if this layout is ever to progress!

Another factor has been cost, which has pretty much ruled out Fast Tracks for now, and lest I waste further money on unsuitable products, I've decided to 'back off a little' in attempt to stop my enthusiasm running away with me. One very good reason for this drawing of breath is that I await an update from Dave who has kindly offered to let me know the outcome of some provisionl tests with the Shinohara products..........when they eventually arrive.....although he's confident its imminent

Anyway, "what's the point of this post?" I may well here you ask, bearing in mind those of you who have dared....sorry.....'cared' to follow any of this half-baked nonsense to date.

Well, I couldn't quite kill my blind enthusiasm whilst sitting twiddling my thumbs, so, armed with some offcuts of Peco Code 75 rail, sheets of tables and dimensions downloaded from the NMRA site, a vernier gauge, a couple of track templates courtesy of Fast Tracks' site and the old adage 'nothing ventured.....' echoing about the grey matter, I set about producing this:

(apologies for the poor quality of this one)

You can see the first I built at the top of the photo; okay, but not as good as the second, which is the one with full 'ties'.

The process was much improved and made a whole lot easier, after I thought about using a gauge to steady the rail against while soldering. A couple of off cuts of aluminium from a door plate (0.047" thick, one thousandth of an inch less than the standard I'd been using - although NMRA states a target of 0.044" for flangeway) purchased for the purpose of producing those excellent 'Heath Robinson' manual turnout controls fabricated by Kurt, came in useful here.

Probably the most laborious part of the construction has been the fabrication of the ties. I couldn't source any wood of suitable proportions locally so ended up laminating a couple of thin sheets of veneer type material that I had lying around in order to match the height of the PCB strips. I almost ended up losing the will to live!

It's not finished yet and I've still to wire it electrically for further testing, however, early signs are good: the truck you see flies through undaunted and although my sole loco has yet to traverse under its own steam, there doesn't appear to be any resistance due to loss of gauge and, reassuringly, no apparent 'wheel drop'.

I shall conduct some tests tomorrow and get back to you - although, if I don't, you'll know that this has also gone pear shaped and I've taken up the far simpler past time of placing ships in bottles

Regards for now,

Jonte