06-06-2012, 06:02 PM

I already had slotted holes cut through the table under the switch throw bars so the next step was to align the pin with the hole in the switch throw and screw the bell crank to the bottom of the table. I put a #8 flat washer on both sides of the bell crank to give a little clearance for the line and the rubber band. I then stretched the rubber band enough that the points were held firm against the normal position stock rail and screwed a 1 inch drywall screw into the bottom of the layout in the right location to hold that tension.

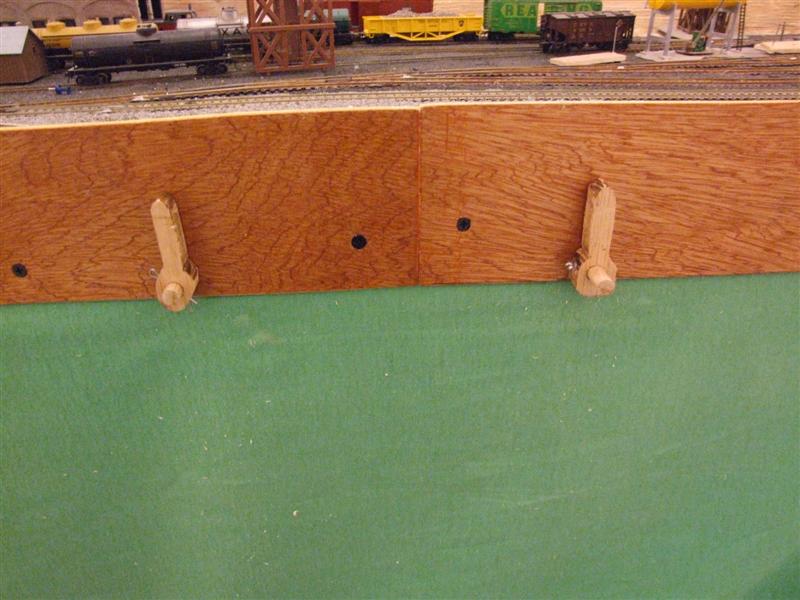

The next step was a 9/16 staple driven loosely into the bottom of the table directly over the place where the dowel rod will come through the fascia. Thread the fishing line through the staple and tie it through the center hole in the dowel rod. (you don't have to worry about the length of the line as long as it is long enough.) Now drill a tight 3/8 in hole through the fascia.( I used a forstner bit). Place a cotter pin through the hole that will serve as stop to keep the dowel from pulling clear through the hole. Wind the dowel clockwise until the points start to move, then unwind a hair until the normal position points are snug against the stock rail. Hold the dowel firmly in this position from the back side and place the lever on the dowel. (I put mine on facing 12 o'clock) Drill from the 4 o'clock position to the 10 o'clock position and insert a short cotter pin to hold it in place. Now if it is set right the switch should go to diverging with the lever approximately 90 degrees, the beauty being you don't have an absolute stop on the lever so you can turn the dowel until the switch points are snug.

I have two switches completed, and parts made to do 50 more. Cost for each switch is less than $.60 for material.

Cheap Charlie...

The next step was a 9/16 staple driven loosely into the bottom of the table directly over the place where the dowel rod will come through the fascia. Thread the fishing line through the staple and tie it through the center hole in the dowel rod. (you don't have to worry about the length of the line as long as it is long enough.) Now drill a tight 3/8 in hole through the fascia.( I used a forstner bit). Place a cotter pin through the hole that will serve as stop to keep the dowel from pulling clear through the hole. Wind the dowel clockwise until the points start to move, then unwind a hair until the normal position points are snug against the stock rail. Hold the dowel firmly in this position from the back side and place the lever on the dowel. (I put mine on facing 12 o'clock) Drill from the 4 o'clock position to the 10 o'clock position and insert a short cotter pin to hold it in place. Now if it is set right the switch should go to diverging with the lever approximately 90 degrees, the beauty being you don't have an absolute stop on the lever so you can turn the dowel until the switch points are snug.

I have two switches completed, and parts made to do 50 more. Cost for each switch is less than $.60 for material.

Cheap Charlie...