07-28-2010, 06:47 PM

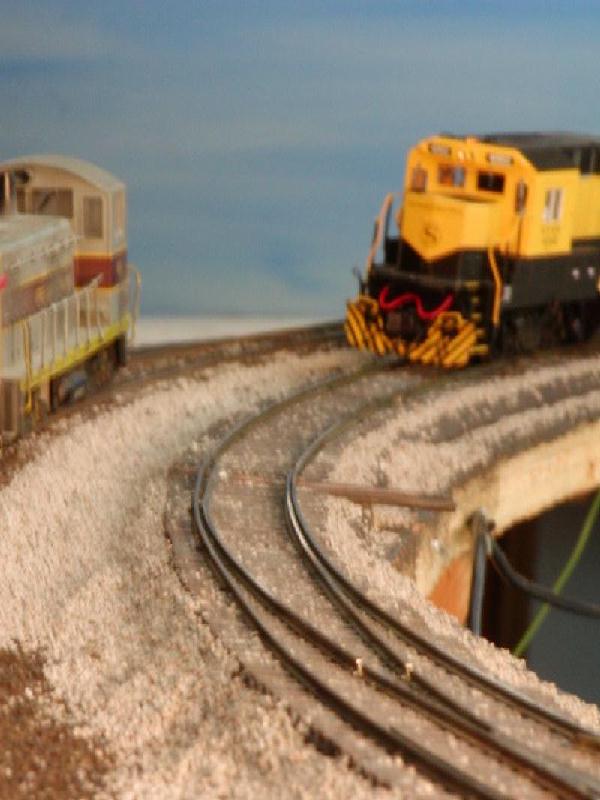

A couple weeks ago I finally started a reconstruction project I had known should be done for some years but couldn't bring myself to tackle. I have a turn back curve which I superelevated, which I've done successfully in the past. I must've miscalculated and not caught it, because the final result was just too much. Here are a couple pics, they show how a train looks in the curve. The first one is terribly out of focus, sorry. But it shows a key turnout well. This turnout was built because I wanted a passing siding turnout within reach of the end of the peninsula (why is another story!). I also wanted no interruption to the 30" radius turn back curve. So I used lathe to mark the routes for a track on a 2 inch center to merge with the 30" radius. Believe it or not, most trains went thru both routes really smoothly. You did notice I said most. I first noticed that certain brass locos would short at multiple places along the curve. One I noticed the pilot hitting the outside rail. Others must have been in the valve gear or brake hanger. Then I found that coal hoppers went thru smoothly empty, but when I added loads, those cast ones that tend to make cars top heavy caused them to tip over, creating an environmental disaster! Luckily I was ready for it, no trains were injured in the making of this story. The second pic shows a switcher on the Garfield branch waiting for a train to pass. The turnout in the distance connects teh branch to the main. It also was built to maintain a constant 30" radius to the main line, while the branch departs from the outside of the curve. The superelevation here made the laying of ties for the branch side of the turnout interesting, as I wanted the superelevation on the branch to end as quickly as possible. You can see that in the pic. Well, rework is in process, and I'll show some progress pics soon.