Posts: 24

Threads: 8

Joined: Dec 2008

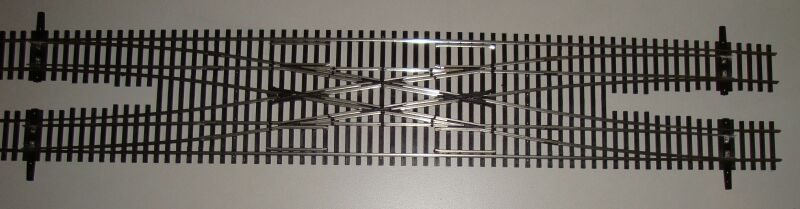

Well I am putting one of these on my layout.

I decided that it would only make sense for all four points to either make both tracks run straight though or all four set to make both tracks cross over.

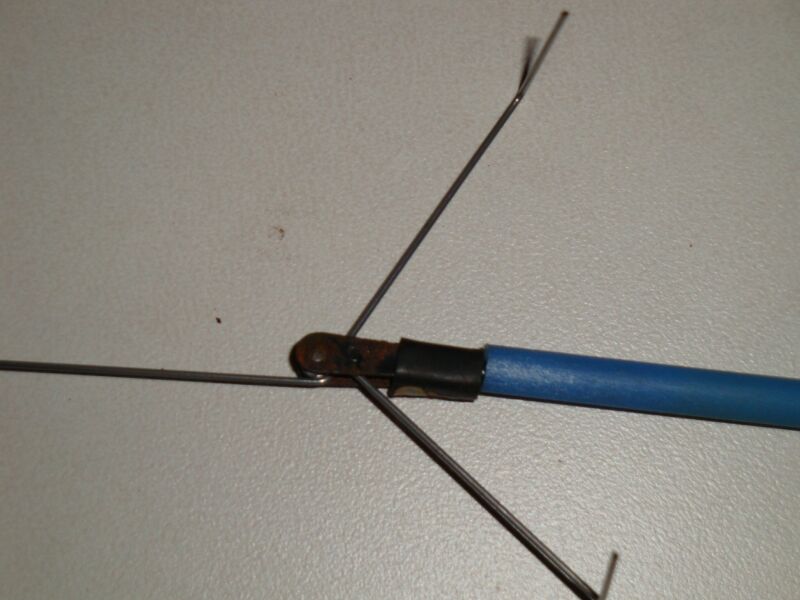

I experimented with some thin soft wire to see if I could move both points at one end.

This worked well, so next I bent some .032 piano wire to the same shape.

This one didn't work all that well. Pushing on the center of the bent wire took a lot of force to move from the closed (straight through) position to the open (cross over) position.

So I made the bent two pieces to make my shape. Each had a small loop at the center position.

Posts: 24

Threads: 8

Joined: Dec 2008

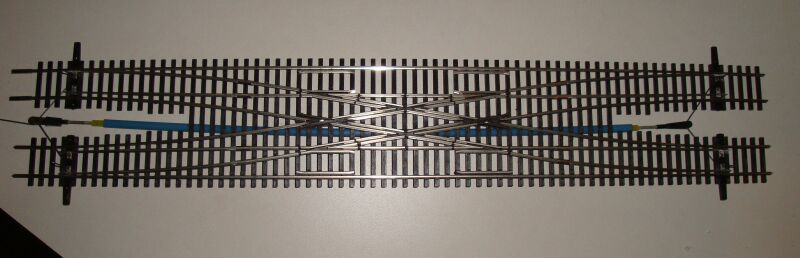

I had a "Gold N push Rod" from my RC airplane flying days, which I cut to the length of the turnout.

Each end has a clevis which I attached my two control wires to.

On the second end I extending one of the wires to allow controlling the turnouts.

The final assembly looks like this.

The rod slides very smoothly and requires about 1/4 inch of movement to throw all switches.

I will attach it under the plywood and cork that the turnout sets on.

Now the final part yet to be done is the motor to control this. Will a Tortoise machine give me the 1/4 inch of action?

Kent

Posts: 24

Threads: 8

Joined: Dec 2008

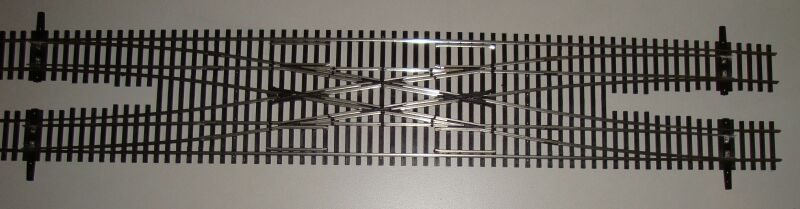

Here is what it looks like when it is under the turnout.

Posts: 315

Threads: 7

Joined: Jan 2009

thats pretty sweet

,i have never heard of a that pushrod before,even being in RC (although im into buggies).looking at those,your idea may end up on my layout also

.great job

--josh

Women may not find you handsome,but they'll atleast find you handy--Red Green

C&O ALL THE WAY--

![[Image: chessie.gif]](http://i573.photobucket.com/albums/ss172/joshwaddle614/chessie.gif)

Posts: 437

Threads: 24

Joined: Dec 2008

That is slick ! Great job of engineering

Loren

I got my first train when I was three,

put a hundred thousand miles on my knees.

Posts: 1,897

Threads: 40

Joined: Dec 2008

Kent, the Tortoise has a long bar that the linkage fastens to. By sliding the linkage along the bar you can adjust the throw. I don't think 1/4 inch is a problem.

Posts: 24

Threads: 8

Joined: Dec 2008

Russ Bellinis Wrote:Kent, the Tortoise has a long bar that the linkage fastens to. By sliding the linkage along the bar you can adjust the throw. I don't think 1/4 inch is a problem.

Great Russ, I'll report back after the final installation on the preformance.

Kent

Posts: 24

Threads: 8

Joined: Dec 2008

Well, I got my tortoise machines and started installing the linkage under the table. Ran into a problem right away. The linkage work OK when under the switch, but when I added the 1/2 plywood and the cork roadbed the linkage coming up through the layout now had do much slop in it.

The points would not always make correct contact with the rail.

So now I am working on using one switch machine on each end with much shorter linkage.

I'll post pictures if I get this working.

Kent

Posts: 1,897

Threads: 40

Joined: Dec 2008

I think you could use one Tortoise machine with 5 bell cranks. You would use one bell crank for each set of points and one to move all 4 with one Tortoise machine hooked up to it. It would take some design work to locate all of the bell cranks and I don't know if the extra bell cranks would end up costing as much or more than the Tortoise machines.

,i have never heard of a that pushrod before,even being in RC (although im into buggies).looking at those,your idea may end up on my layout also

,i have never heard of a that pushrod before,even being in RC (although im into buggies).looking at those,your idea may end up on my layout also  .great job

.great job ![[Image: chessie.gif]](http://i573.photobucket.com/albums/ss172/joshwaddle614/chessie.gif)