11-20-2021, 09:59 AM

Thought I would share another project I'd doing for another modeler. On Vancouver Island Canadian Forest Products (Canfor) had a logging railway line and used modified SW1200 engines.

CANFOR Englewood Logging Division 303 (trainweb.org)

The large box in front of the cab is the EMD installed dynamic brakes. They also added extra air tanks on the hood due to the steep grades these units ran over.

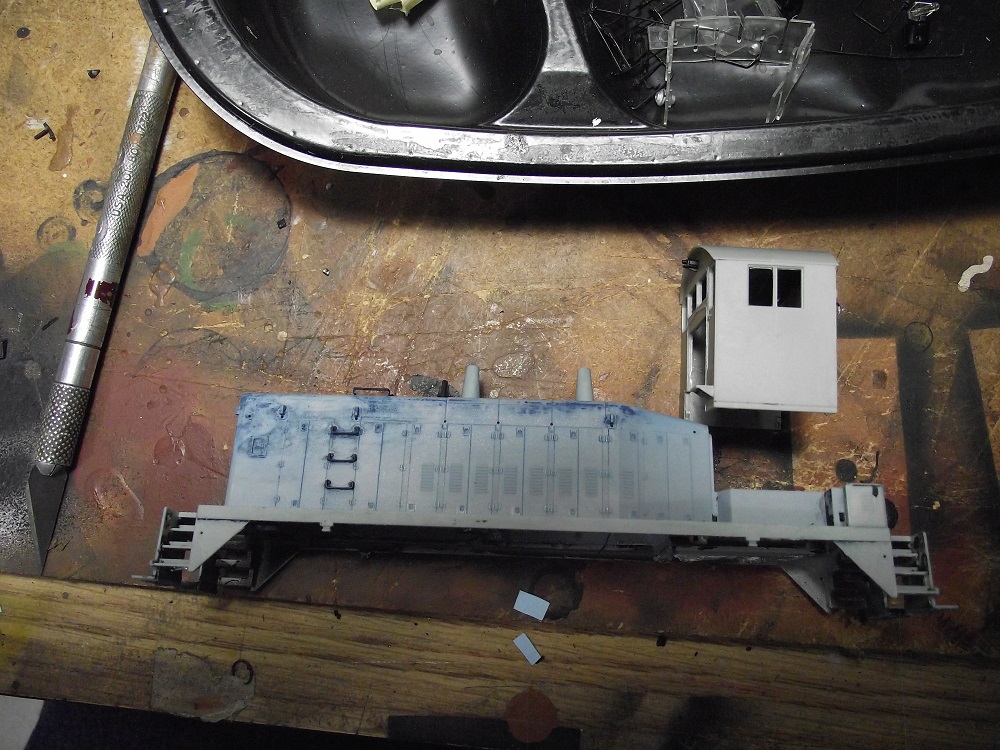

The fellow that want this model started with a Proto2000 engine but didn't really know how to modify the shell.

To make the 'box' he simply made it out of cardboard and white glued it to the shell. This is how I got the model.

I was able to remove the box and strip the shell. Then came the modifications.

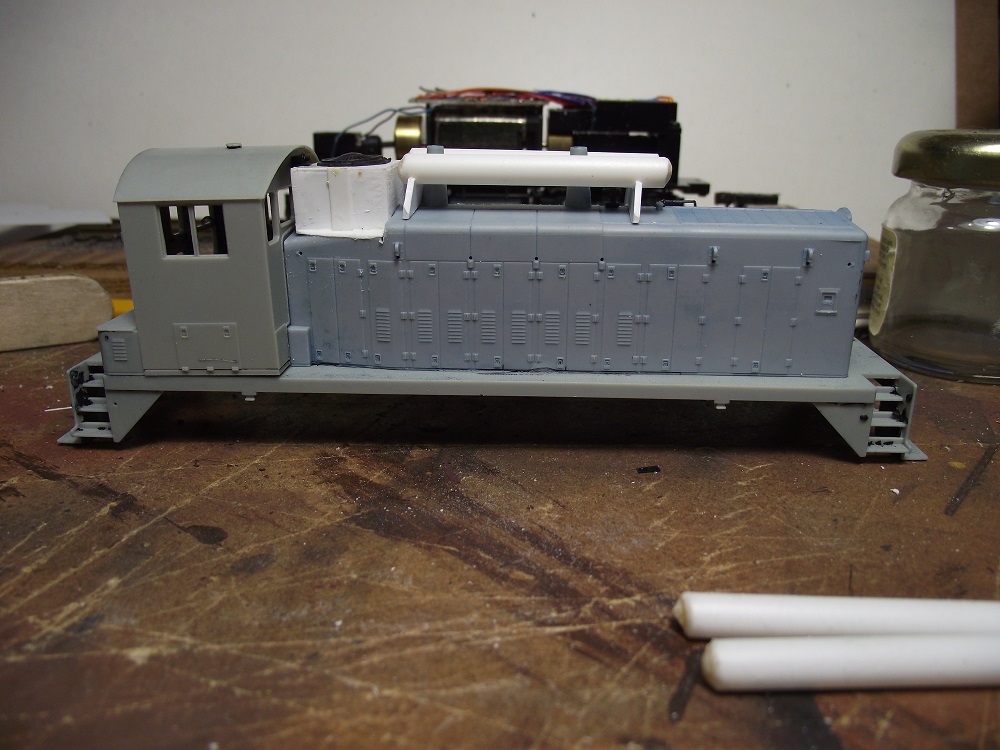

I made a new dynamic brake box out of sheet styrene and a 36" fan I got for an old F-unit shell. I also had to cut the hood down to accommodate the new 'box' this had to be done very carefully as the original circuit board lies just under the hood.

I should also note that I'm building a representation of the Canfor engine, not an exact replica. I'm guessing most of the parts dimensions by studying the photos that I have found.

Then I had to fabricate the air tanks and their mounts. The tanks are styrene tubing, filled with putty. I sanded the ends round. I had a bit of a challenge with the mounts as the tanks straddle the exhaust tanks and the top of the hood is slightly round. I made a card pattern, followed by a styrene master.

Now you may wonder why four tanks and mounts? Well another modeler saw the project and now I'm building a second unit. It was just easier to build all the parts at the same time.

Ready for paint. The air tank assembly is just loose for now.

This is how it sits now, very yellow. It took 4 coats of Model master acrylic yellow to cover

CANFOR Englewood Logging Division 303 (trainweb.org)

The large box in front of the cab is the EMD installed dynamic brakes. They also added extra air tanks on the hood due to the steep grades these units ran over.

The fellow that want this model started with a Proto2000 engine but didn't really know how to modify the shell.

To make the 'box' he simply made it out of cardboard and white glued it to the shell. This is how I got the model.

I was able to remove the box and strip the shell. Then came the modifications.

I made a new dynamic brake box out of sheet styrene and a 36" fan I got for an old F-unit shell. I also had to cut the hood down to accommodate the new 'box' this had to be done very carefully as the original circuit board lies just under the hood.

I should also note that I'm building a representation of the Canfor engine, not an exact replica. I'm guessing most of the parts dimensions by studying the photos that I have found.

Then I had to fabricate the air tanks and their mounts. The tanks are styrene tubing, filled with putty. I sanded the ends round. I had a bit of a challenge with the mounts as the tanks straddle the exhaust tanks and the top of the hood is slightly round. I made a card pattern, followed by a styrene master.

Now you may wonder why four tanks and mounts? Well another modeler saw the project and now I'm building a second unit. It was just easier to build all the parts at the same time.

Ready for paint. The air tank assembly is just loose for now.

This is how it sits now, very yellow. It took 4 coats of Model master acrylic yellow to cover