Posts: 1,263

Threads: 45

Joined: Feb 2010

Mike Kieran Wrote:Actually, a food processor would add ingredients to the food like preservatives, corn syrup, fillers, etc. Justin has a point, just an incorrect example as well as Lance Mindheim's example. While they may distribute these foods, the foods are actually processed at a central location. The averagae chicken nugget has only 50% chicken meat in it. Guess what the rest of it is. Hint - it comes in in covered hoppers and tank cars. Mike;

We are of course talking about two different types of industries here. Guess I should have made the point clearer. The type of facility that I currently have on my layout does not actually process any foods, but is simply the distributor of various food products and food service items. But it still has a good variety of freight car types that would be spotted there. In that regard, the term "food processor" would not be correct.

For an example of a facility that is actually a "food processor"; take your chicken nuggets (Please!). A company like Tyson would, at one facility, process the chickens (even raise them near the plant) , add preservatives and what other ingredients they include (do we really want to know?) then package and ship out the finished product to distribution centers. Same thing with the example of the soup plant, all the ingredients of the various soups would be "processed" at the plant and then the finished product shipped out. These would be large facilities too.

Those are some interesting examples that you and Larry are suggesting for possible model railroad industries and could be something to model on an ISL type layout. Will have to spend a little time looking around on Google/Bing and see if I can find some examples of those types of facilities or perhaps you or Larry can point me to some.

Ed

"Friends don't let friends build Timesavers"

Posts: 1,897

Threads: 40

Joined: Dec 2008

I think that typically a "food processor" or a canary would be located in a location relatively near their "raw material" source. Example-Tyson foods is located in Arkansas near the chicken ranches. Can goods can be shipped all over the country by rail since it really isn't considered perishable. Fresh meats are shipped in refrigerated trailers more often I think because it is somewhat perishable, and may not be delivered quickly enough by rail. Frozen foods are often delivered great distances by rail because if kept frozen they are also not considered perishable. Fresh produce is shipped on rail only when it can go directly from port to port without having the cars switched around through a lot of yards.

On the other hand a food distributor like Sysco sells fresh produce, fresh meat, fresh seafood, as well as institutional sizes of canned goods, and cases of frozen french fries and other frozen products. They also handle fresh bread and bakery products, I think. Before I retired, our biggest customer was Sysco. They had a service agreement with our company that required us to have a mechanic working at their location on their reefers daily and I did a lot of service calls for reefers that quit working while delivering product as well as call outs to reefers that were parked at customer's location for food storage. I think the warehouse in Walnut, Ca had about 600 refrigerated trailers. They had another 120 trailers in San Diego that our San Diego shop took care of. In addition they had warehouses in Phoenix and Las Vegas that would take care of customers in the Eastern part of So California. I don't think they even had rail service to any warehouse in So. Cal., but that doesn't mean that they would not have rail service on the East Coast.

Posts: 612

Threads: 10

Joined: Feb 2011

By the way Ed, please forgive my belated, wishing you a  and may you have many a good year ahead to indulge your love of trains.

Thanks once again for taking the time recently to drive to Effingham and take those photos of the EFRR for everyone. Very much appreciated as every view helps and everytime photo is viewed something more can be noted.

Mark

Fake It till you Make It, then Fake It some More

Posts: 1,263

Threads: 45

Joined: Feb 2010

Russ Bellinis Wrote:On the other hand a food distributor like Sysco sells fresh produce, fresh meat, fresh seafood, as well as institutional sizes of canned goods, and cases of frozen french fries and other frozen products. (...) No substitute for first hand information Russ! Sysco appears to have far more locations in my part of the country and I've looked at a lot of them on Bing/Google. Some are and some aren't rail served and as you pointed out, many of their facilities are really large. They have a large distribution facility nearby in Louisville and you guessed it - no rail service, although it is located in a large CSX served industrial park. On the other hand I've looked at some of their facilities in other locations not far from here that are rail served.

There are many other such companies in my area performing the same service and again, some may be rail served and some strictly truck served. Examples: Gordon Food Service, Sherwood Food Distributors, Laurel Grocery Company and many more. So I have a wide range of prototype facilities (and company names) that I could base my "Food Distribution Facility" on.

There used to be a rail served food distributor called Institutional Jobbers (based out of Knoxville, TN) nearby and a relative worked there in the warehouse section. I toured the facility with him one evening. On that particular night they had a box car load of various Kellogg cereal's that they were unloading and stocking in the warehouse as they also picked and filled orders for delivery by trucks. He told me that they would get a refrigerator load of meat or poultry now and then along with other assorted commodities, but of course the majority of products came in by truck. We also had a Hardee's distribution facility right here in town that received french fries in reefers, but no other commodities. Just two examples and it all depends on what the facility is and what they actually receive/ship by rail.

As you stated, actual "food processing" facilities seem to be located close to their material source and everything pertaining to the "processing" is handled in one location. These days, so many products that are produced (food and otherwise) often get their raw materials in by rail, but ship nothing out by rail and for many reasons. Delivery times being the biggest consideration.

In Owensboro, KY, we have the one and only Ragu' sauce plant in the US (located on Ragu' Drive naturally) and it is rail served, although I'm not sure what commodities they may be receiving. Track runs inside their structure, so Google aerial and street views aren't much help. Just guessing, I assume that tomato paste might be a logical commodity since tomatoes, although grown around here, don't seem to be a cash crop in that part of the state. But I could wrong about that part. Were I interested in perhaps modeling this facility, then I'd certainly try and find out what sort of rail service they do get and what commodities, rather than just guess or dream up commodities.

A previous posting about soup plants got me interested in looking for such facilities, so right now, I'm looking for locations of Campbell Soup plants to see what sort of rail service they may or may not have. I believe that Campbell Soup started in Brakie's part of the country in Napoleon, Ohio, so perhaps he's actually seen it. It's really not something that I'm interested in including on the layout, but it's more a matter of getting information. Always interested in a possible industry to include on the layout, and at the same time educating myself about what they may or may not ship/receive by rail. UPDATE: See this thread http://www.the-gauge.net/forum/viewtopic...=24&t=4868

As I mentioned in my previous posting; any time some one suggests such and such an industry, I'd sure like to see examples to get a better idea of what they do ship/receive by rail. Always open to interesting subjects.

Hey there Mark! Thank's very much for the birthday wishes. As for it being late - no big deal. I more or less stopped observing birthdays some time ago as I realized that I was getting closer to the end then the beginning LOL.

I sure hope the health issues sort themselves out in the next few weeks, as it is still preventing me from doing a lot of things on the layout that I want to do. As for the trip to Effingham, I really enjoyed going by there again and seeing what had changed, etc. It was a shame that I didn't have time to hang around and perhaps actually get to photograph or video them working. It's one neat little operation! Hope that perhaps one day in the near future, you'll get the chance to visit Effingham yourself. Long haul from AU to Central Illinois USA.

Ed

"Friends don't let friends build Timesavers"

Posts: 2,269

Threads: 181

Joined: Dec 2008

I recommend "How It's Made" and "How Do They Do That?" on television as a great source of information on what arrives at various plants and how it is delivered.

Although the "How It's Made" series is produced in Canada, the basic info seems to be consistent across the board and it's interesting to see the various ingredients or raw materials arrive and depart during the manufacturing process.

A modeler might also consider that even though the prototype factory isn't using trains, yours can if you wish.

Posts: 3,262

Threads: 115

Joined: Dec 2008

MM:A modeler might also consider that even though the prototype factory isn't using trains, yours can if you wish.

-------------------------------

I've done that several times over the years and even my planned Slate Creek has a industry that is rail served instead of truck served like the its prototype.

Larry

Engineman

Summerset Ry

Make Safety your first thought, Not your last! Safety First!

Posts: 1,263

Threads: 45

Joined: Feb 2010

That's the nice thing about model railroads (freelance especially). We can have a rail served industry that really isn't rail served. We can find a prototype industry that no longer has rail service and on our layouts, have them using it again. As long as it's believable and interesting - it's our choice.

You can find all sorts of interesting prototypes (with or without rail service) to base your industries on. You see an interesting or unusual structure, spend a little time finding out what they do at that industry and then you can build your structure based on it or come up with your own unique design then determine what sort of rail traffic they might receive and go with it. So many things you can do in this hobby! No wonder some of us can't ever settle on one thing!

Ed

"Friends don't let friends build Timesavers"

Posts: 2,269

Threads: 181

Joined: Dec 2008

FCIN Wrote:So many things you can do in this hobby! No wonder some of us can't ever settle on one thing!

Maybe that's because for many of us the creation part is the most fun!

Posts: 1,263

Threads: 45

Joined: Feb 2010

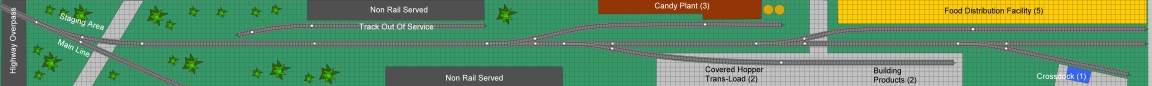

Since I'm still playing around some with slight track plan variations of my original plan(s); just for the fun of it, I drew up a track plan based on Lance Mindheim's Palmetto Spur track plan, but expanded to fit my bench work:

Even though I'm not that wild about having a long trans-load track on the layout, it does have possibilities and can include some interesting mini-scenes. Plenty of interesting ideas in the Industries Along The Rails topic section.

The deceptively simple track plan provides plenty of operation; just take a look at alcanman's Palmetto Spur layout http://www.the-gauge.net/forum/viewtopic...=46&t=4317 and what he's done with that plan.

Main features on my version of this plan are the two large industries: Food Distribution Facility that spots up to 5 cars and the Candy Plant that can spot up to 3 cars. The trans-load track can handle up to 4 cars for various off-line customers, such as building products, a feed/fertilizer dealer unloading covered hoppers with a portable conveyor and the small crossdock structure where car loads of beer and other miscellaneous commodities might be unloaded. In spite of only having the 3 tracks, the plan still provides destinations for all my equipment types.

I've included the switch leading off the main track to the spur and would stage the train as though it had just entered the spur. This gives a definitive start to the industrial spur, rather than just have the spur end under the highway overpass. Also have a couple of non rail served structures and one out of service track to one of them just to model what you often see around industrial spurs these days.

Since right now, I have a lot of the track off the bench work where I've been playing around with variations of my original plan(s), I may just throw this down today and operate it some to see how it works out. I'd still prefer to have at least one more separate track/industry in many ways, but if this keeps me busy, who knows. If not, then I'll go back to one of the other plans, once I can settle on what industry to place where on those plans.

I'm gradually getting some of my energy back and am getting the urge to start doing something for real, even if it ends up being a simpler track track than I originally envisioned. Had to go get another x-ray of my chest and more blood work done this morning. Man am I sick of being stuck with needles! Go back to the surgeon that installed my DCC decoder next week and if everything is looking and working okay, THEN maybe I can really get going. I'm really wanting to start construction of the food distribution building too, so it may be time to order those large sheets of .060 styrene.

Ed

"Friends don't let friends build Timesavers"

Posts: 1,291

Threads: 64

Joined: May 2011

Hey Ed, a simple track plan means less headaches. A simple transload/team track along the front is a great way to reduce those headaches. I liked the earlier plan, but putting structures along the front edge can be a hassle that some don't have the time or energy for.

When the doc puts your decoder in, ask for one with DCC & Sound so that you can really screw with people's heads.

Mike Kieran

Port Able Lines

" If the world were perfect, it wouldn't be " - Yogi Berra.

Posts: 1,263

Threads: 45

Joined: Feb 2010

Mike Kieran Wrote:Hey Ed, a simple track plan means less headaches. A simple transload/team track along the front is a great way to reduce those headaches. I liked the earlier plan, but putting structures along the front edge can be a hassle that some don't have the time or energy for. Howdy Mike!

I've been doing a lot of self analyzing about just how much to include on my layout as far as industries/tracks. So am actually laying this stretched version of the Palmetto Spur track plan right now. As long as it provides for valid destinations for all my cars (which it does) and has enough switching to keep me busy for 45 minutes to an hour with a typical session, then simpler may be better.

I do like a couple of the earlier plans, even with the industries on the front edge of the plan, but were they weren't so much of a problem with simple structure mockups, adding roof details, etc., might have ended up being a problem. Any way, I'll try this out for a while and see what I think about it.

Mike Kieran Wrote:When the doc puts your decoder in, ask for one with DCC & Sound so that you can really screw with people's heads.  Well according to the wife, I did get a decoder with sound installed - at least when I get upset about something! I guess when I go to see the surgeon next week, he'll test the decoder out and make any necessary changes to the various CV's. After they installed it at the hospital, a representative from the manufacturer did come by the next morning and do a simple slow speed/fast speed test of it, but there are probably some other settings that could be fine tuned. I was told that in "no time at all" I'd feel 10 years younger. I'm still waiting for that!

Ed

"Friends don't let friends build Timesavers"

Posts: 701

Threads: 27

Joined: Mar 2010

Ed, I think this may be my favorite plan, three industries will provide more than enough operation.

Justin Miller

Modeling the Lebanon Industrial Railway (LIRY)

Posts: 1,263

Threads: 45

Joined: Feb 2010

Operated the latest test revision tonight and it took 55 minutes to place and pull 2 cars on each track and with no "time killing" at all, other than just operating at scale speeds. So operationally it's working out okay. In some ways, It is surprising that such a simple looking track arrangement can provide so much operation; although working 3 long tracks, reminds me a lot of switching the distilleries back in the good old days, and that was quite time consuming.

I did adjust the number of car spots at the food distribution facility (5 rather than 6) and the candy plant (3 rather than 4) as it was a better car spot ratio to structure size.

After operating it, I'm wondering if perhaps I should add one more track back on the plan and place the crossdock on a separate track and split the trans-load track at the street crossing, with building products unloading on one side of the street (perhaps in a fenced in area) and covered hoppers being trans-loaded to trucks on the other side. Like this:

Not sure that it would really add much operation wise, but I'm not sure that I like the really long trans-load track as it is on the current test plan. Just seems like adding the other short angled track, fills in the right hand side of the plan a little better.

Still experimenting, so I'll operate it a bit more and see what develops.

Ed

"Friends don't let friends build Timesavers"

Posts: 701

Threads: 27

Joined: Mar 2010

Ed, I would make the new track be the the building products, and then put the crossdock back on the team track.

Justin Miller

Modeling the Lebanon Industrial Railway (LIRY)

Posts: 1,291

Threads: 64

Joined: May 2011

Ed, I would just leave the crossdock where you had it on the October 11 plan. or put it between the covered hopper transload and the building products to visually break up a long siding.

Mike Kieran

Port Able Lines

" If the world were perfect, it wouldn't be " - Yogi Berra.

|

and may you have many a good year ahead to indulge your love of trains.

and may you have many a good year ahead to indulge your love of trains.