Posts: 992

Threads: 63

Joined: Mar 2015

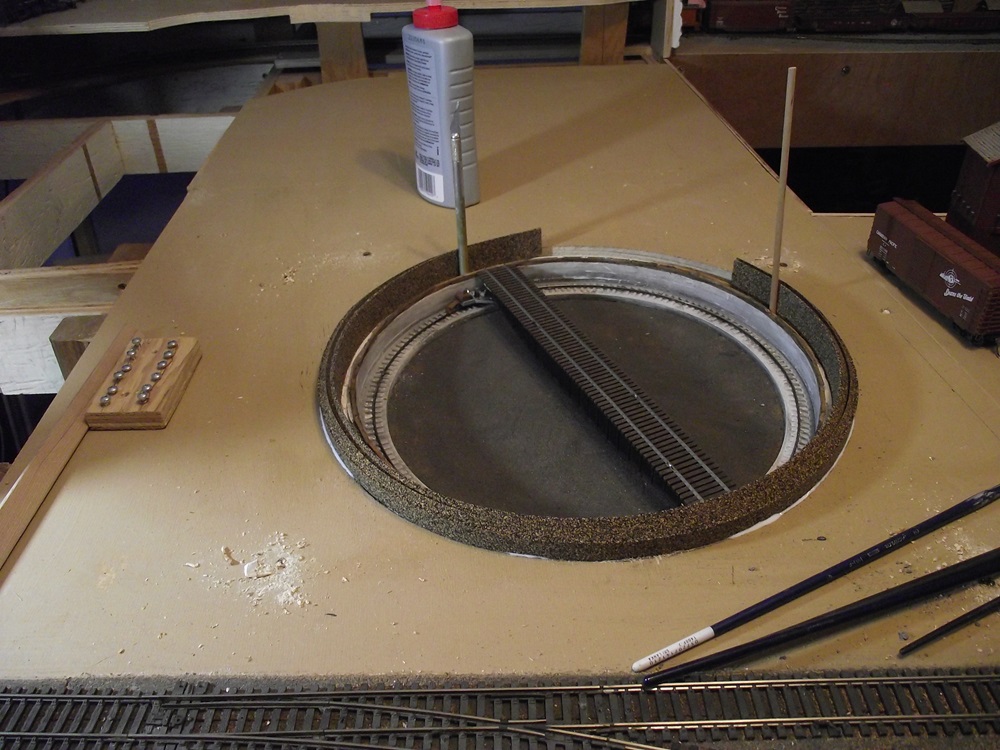

I got the turntable backfor the second time. My friend added a pickup wiper to the one end:

Not quite as un-noticable as one might hope but it does the electrical pickup job. My friend made a video of it in action:

Glen’s Diamond Scale H.O. Turntable - YouTube

The test car on the turntable has a light in it that will stay on as the table rotates.

Posts: 1,310

Threads: 34

Joined: Mar 2009

Looks great and is running smoothly.

Matt

Conrail's Blairsville Cutoff - A Fictitious Alternative Route Over The Allegheny Mountains From Blairsville, Pa to Cresson, Pa

Milepost 363.8 to Milepost 338.9

Posts: 992

Threads: 63

Joined: Mar 2015

Thanks Matt.

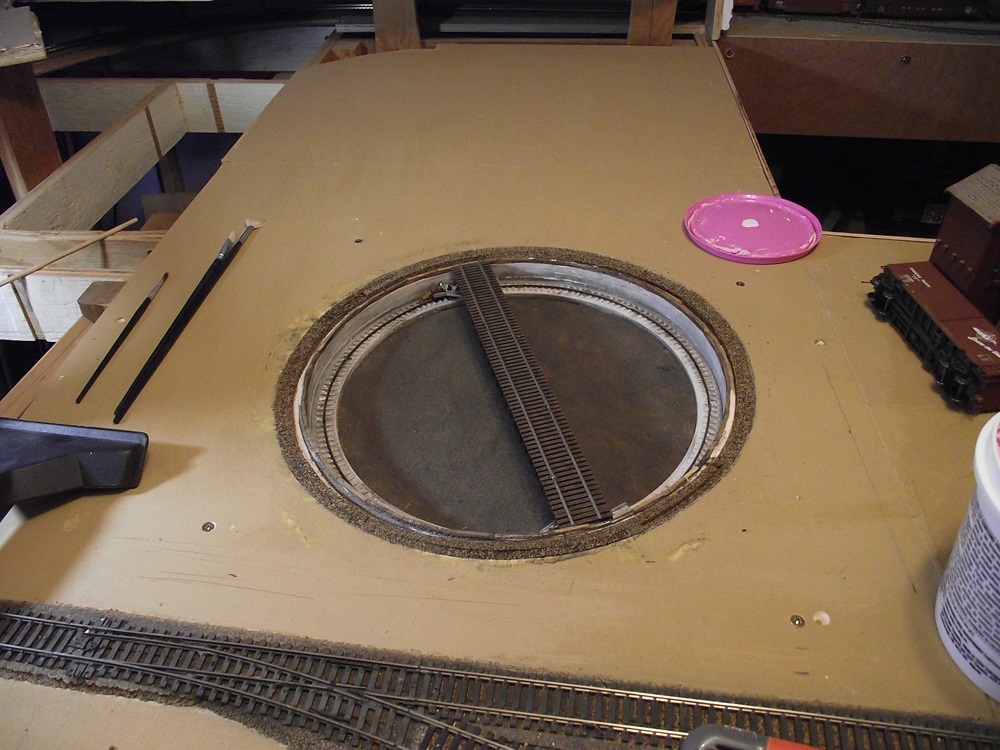

My friend came over today and we installed the turntable on the layout:

He held it under the layout while I drilled and screwed from the top a screw at each corner, going through the spacer blocks makes for a solid platform.After it was installed I checked my measurements and my 3/4" spacers did the trick. The bridge track will be level with any code 70/83 track that it connects with.

Now the next challenge is to fill the gap around the turntabe pit. There is about 5/8"gap that's 1/4" deep. I'm thinking of gluing cut down cork roadbed to fill, sanding to flush and then filling any other gaps with some wall filler. I'm trying to keep the fix as mess-free as possible so anything liquid is out.

Another item on the way is the control module for the turntable motor. I found a neat device on Abay and it should be here in the next couple weeks. (coming from China)

Posts: 1,310

Threads: 34

Joined: Mar 2009

You're Welcome. Looking good and nice to see you got it installed. I may not have enough experience but I agree with you on how to fill it in. I'm sure they are other ways but that seems to be the easiest.

Matt

Conrail's Blairsville Cutoff - A Fictitious Alternative Route Over The Allegheny Mountains From Blairsville, Pa to Cresson, Pa

Milepost 363.8 to Milepost 338.9

Posts: 992

Threads: 63

Joined: Mar 2015

I'm not sure if it was the easiest but it's pretty close to how it was mounted in it's previous home.

I did get the gap filled today:

I ran the cork twice inside the gap on it's edge (I wasn't sure if it would flex around an 11" diameter witout breaking) and glued it in place.

Then I trimed it down flush with the layout and used some of the scraps to fill the larger gaps that were left.

When that had all dried, I used some spackle to fill in an spaces that the cork didn't. Don't worry about the pink, this stuff turns white when it's dry so you know when it's okay to sand.

Posts: 1,310

Threads: 34

Joined: Mar 2009

Looks great. I see you went with the cork roadbed.

Matt

Conrail's Blairsville Cutoff - A Fictitious Alternative Route Over The Allegheny Mountains From Blairsville, Pa to Cresson, Pa

Milepost 363.8 to Milepost 338.9

Posts: 992

Threads: 63

Joined: Mar 2015

Thanks Matt.

I finished off fitting the turntable in

It took 3 fills and sandings to get the space around the turntable finished for painting. I brushed some tan paint on to blend all the sanded spackle in. I'm still waiting for the control module for the turntable and until I can turn to bridge I can't lay track and get a proper alignment. In the meantime, I'll continue to work on the enginehouse project.

Posts: 1,310

Threads: 34

Joined: Mar 2009

You're Welcome. That looks great glen. Can't wait to see this area finished.

Matt

Conrail's Blairsville Cutoff - A Fictitious Alternative Route Over The Allegheny Mountains From Blairsville, Pa to Cresson, Pa

Milepost 363.8 to Milepost 338.9

Posts: 267

Threads: 12

Joined: Dec 2008

Fantastic progress from scratch, in such a (relative) short time Glen, even hand-laying some track to boot.

And I am impressed with the simplicity of the brilliant little terminal block you made, genius. Will be interested to see more as you develop your layout.

Jack

LIFE....

..... Abandon the search for truth

Look for a good fantasy

Posts: 992

Threads: 63

Joined: Mar 2015

Thank you. I haven't been working on the layout for the past months because I've got the enginehouse under construction. When that is done I can continue to finish up the trackwork on the engine facility.

Posts: 992

Threads: 63

Joined: Mar 2015

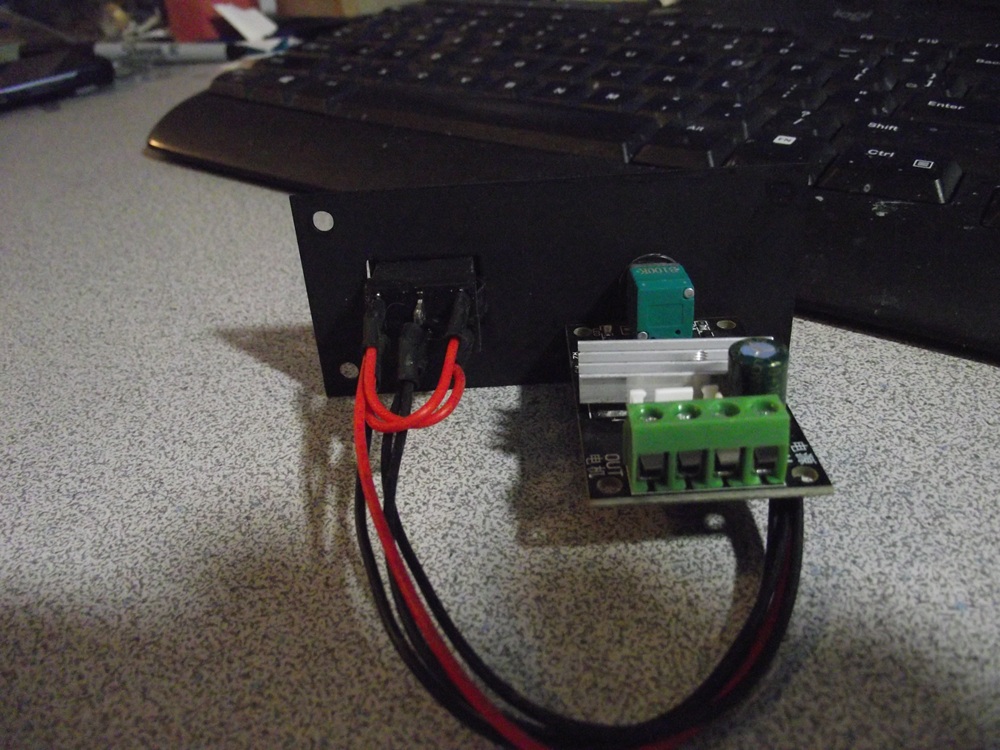

Now that the enginehouse is pretty much finished, I can focus on installing it on the layout. Before that I need to power the turntable so I can line up the tracks. I needed a controller that was small, easy to install and came with a reversing switch.

I found this DC motor controller on Ebay. It's a Pulse Width Modulated unit with a reversing switch included. It can be bought for about 20$ with shipping.

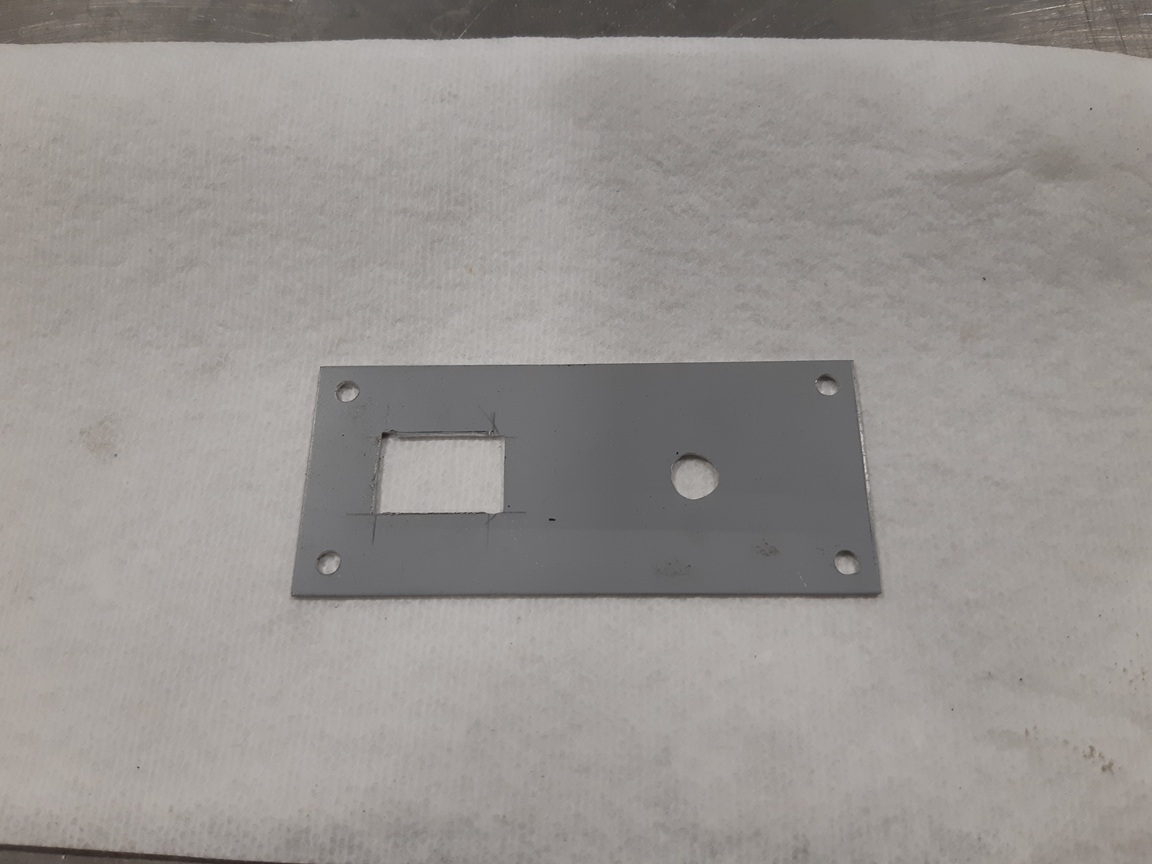

I made a mounting plate for it from a small piece of aluminum sheet.

Painted black and with the controller installed. The controller is input polarity specific, so it might take a couple tries before getting it right. I used a small 12 volt transformer to power it.

I cut a hole in the fascia and it slipped right in. I choose to place it inside the pit, close to the turntable/engine facility so you can eyeball lining up the tracks.

Posts: 1,222

Threads: 18

Joined: Jun 2022

Well done, Glen! Can't wait to see the engine house in place.