03-12-2012, 10:51 AM

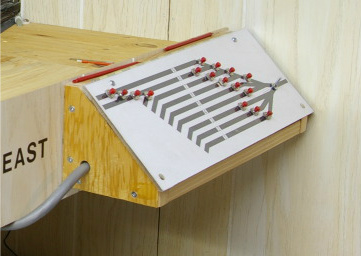

I used 1/8th inch Masonite for some of my panels, with computer printouts for the diagram. A club member works in an architects office and he designed and printed them for me. He made a revers copy also for the back side of the panel to make it easier to see whats what when the lid is open. The paper was glued to the Masonite with spray adhesive and a sheet of clear plastic was placed over the top. The plastic was salvaged from a plastic box lid and is held in place by the upper hinge screws and two rivets in the lower corners. I then drilled the holes for the push buttons using a 1/4 inch forstner bit in a drill press. This panel is 5x15 inches in size and the push buttons are at leased 3/4 of an inch on center or better for finger clearance. The box as fastened to the layout by two bolts with wing nuts, and electrical connection is made though a Jones Plug. This way it can be quickly removed if necessary. I also like to include a terminal strip so that wires can be disconnected for testing purposes in case of problem. Hopefully this may be of help.

Robert

Modeling the Canadian National prairie region in 1959.

Modeling the Canadian National prairie region in 1959.