If the detail part has a mounting pin, drill the boiler casting to accept it, and if the fit of the pin in the hole is fairly tight, use ca to affix it permanently. If the fit is a bit sloppy, epoxy would be a better choice.

For parts with no mounting pin, you can drill the back of the part to accept a piece of wire - music wire or brass will work, and use a wire size appropriate to the size of the detail.

Where there are pipes running to details, drill the detail part to accept the proper diameter of pipe

before mounting the detail part. Usually, such parts have a depression in the casting wherever a pipe is to be attached, but drilling it deeper will allow a much stronger joint. Keep in mind, too, that prototype pipe sizes are for the

inside diameter (somebody wasn't aware of that, and that's why all of the piping on the Proto 0-6-0s and 0-8-0s was undersize)

.

I like to solder the pipes to the details where possible and with some care and some tape, the parts can be temporarily placed where they're supposed to go, then the pipe bent to suit. If you've drilled out the holes as suggested, and cleaned the wire used for forming the pipes (drag the wire through some fine sandpaper before making the bends), all you need to do is add a little flux to the areas to be joined, and a quick touch with some solder and a hot iron will make the joints easily. You can then remove the details with the pipes connected and apply epoxy to the mounting holes and re-install the details. If you're using ca, no need to remove the details...simply place some ca on the tip of your X-Acto, and then touch that to the area wher the mounting pin enters the boiler. The reason for doing the soldering before permanently affixing the details is that excessive heat can weaken or break bonds made with ca or epoxy. Naturally, if you don't care to solder, the pipes can be attached with ca or epoxy, as long as you've drilled out the holes as suggested.

Because the material used for cast boilers is often difficult to drill, I save my modelling drill bits for friendlier material, and use regular drill bits for this work - anything from 1/16" and larger. Drill a suitable such hole where it's needed, then apply some solvent-type cement to a piece of styrene rod (or some sprue material left-over from a plastic kit) slightly larger in diameter than the hole - about .004"-or-so works well. Allow the solvent to soften the plastic a bit (re-coat if necessary), then jam it into the hole 'til it bottoms-out. Let the plastic re-harden, then trim off the excess and sand the area smooth. You now have a nice easy spot to drill a model-sized hole, suitable for wire-type pin mounts, without wrecking another small and expensive bit.

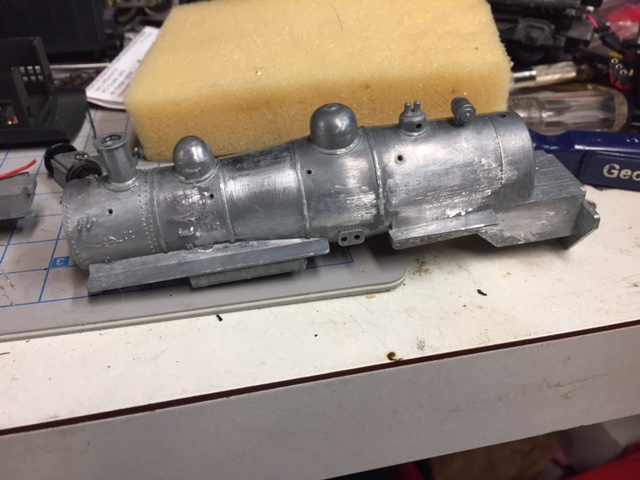

Here's a Proto USRA 0-8-0, re-done to match its prototype as seen in a photo....

![[Image: NewcrewsfortheGrandValley021.jpg]](http://i23.photobucket.com/albums/b399/doctorwayne/Get%20a%20load%20of%20this/NewcrewsfortheGrandValley021.jpg)

These locos have cast boilers...

![[Image: 033.jpg]](http://i23.photobucket.com/albums/b399/doctorwayne/Erie%20Northshore%20Ten-Wheelers/033.jpg)

...and there's a thread

HERE showing the build, including details.

Wayne

![[Image: s-l225.jpg]](https://thumbs.ebaystatic.com/images/g/MYUAAOSw7ThUpCxg/s-l225.jpg)

![[Image: 2-8-0-1303-at-Enid-Oklahoma-on-February-13-1938.jpg]](http://frisco.org/mainline/wp-content/uploads/2015/02/2-8-0-1303-at-Enid-Oklahoma-on-February-13-1938.jpg)

![[Image: s-l225.jpg]](https://thumbs.ebaystatic.com/images/g/MYUAAOSw7ThUpCxg/s-l225.jpg)

![[Image: 2-8-0-1303-at-Enid-Oklahoma-on-February-13-1938.jpg]](http://frisco.org/mainline/wp-content/uploads/2015/02/2-8-0-1303-at-Enid-Oklahoma-on-February-13-1938.jpg)

.

.

![[Image: NewcrewsfortheGrandValley021.jpg]](http://i23.photobucket.com/albums/b399/doctorwayne/Get%20a%20load%20of%20this/NewcrewsfortheGrandValley021.jpg)

![[Image: 033.jpg]](http://i23.photobucket.com/albums/b399/doctorwayne/Erie%20Northshore%20Ten-Wheelers/033.jpg)

![[Image: dsc01028z81l.jpg]](http://abload.de/img/dsc01028z81l.jpg)

![[Image: IMG_0273_zps2yaef65w.jpg]](http://i1081.photobucket.com/albums/j358/bowser0227/IMG_0273_zps2yaef65w.jpg)